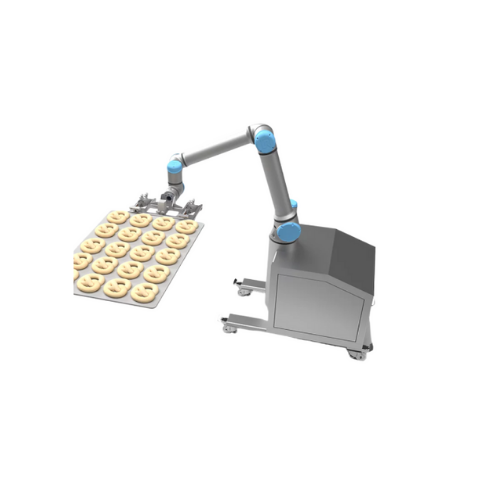

Robotic gripper arm for bakery tray and product handling

Optimize your bakery’s efficiency by automating repetitive tasks like tray handling and dough piece management, ensuring seamless operation even in staffing shortages.

Automates Tray and Product Handling in Bakeries

The WP Robot from WP Riehle revolutionizes bakery operations by automating labor-intensive processes such as tray handling and dough piece transport. This equipment excels with its modularity, allowing seamless integration into existing production lines. Designed to cater to bakeries, food manufacturers, and snack producers, it supports high-speed and continuous operations, effortlessly handling tasks across processing, packaging, and transport departments. The robots employ a versatile system of robotic grippers and suction attachments for efficient gripping, conveying, stacking, loading, unloading, and brushing. This flexibility is particularly beneficial for producing items like bread rolls, pretzels, croissants, and more. Additionally, WP Robot offers collaborative operation potential, minimizing floor space requirements without compromising safety. Constructed for durability, it addresses labor scarcity while maintaining processing consistency and reliability, making it an invaluable asset in modern food processing. Optional customization and engineering support ensure it meets specific production demands effectively.

Benefits

- Enhances productivity by automating repetitive tasks, reducing reliance on manual labor.

- Increases production line efficiency with seamless integration capabilities.

- Adapts to various product types through interchangeable grippers and suction attachments.

- Preserves operational space and ensures safety with collaborative robot functionality.

- Minimizes operational costs by addressing labor shortages with reliable automation.

- Applications

- Dough pieces, Baked goods, Trays, Proofing crates, Bakery products

- End products

- Baguettes, Bread rolls, Cookies, Muffins, Cinnamon rolls, Croissants, Pretzels, Danish pastries, Proofing crate components

- Steps before

- Dough preparation, Tray setup, Machine programming

- Steps after

- Baking, Cooling, Packing

- Input ingredients

- dough pieces, baking trays, proofing crates

- Output ingredients

- processed bakery products, empty baking trays, stacked products

- Market info

- Automation

- Automatic loading and unloading

- Robot Sizes

- Different sizes available

- Gripper Arm

- Exchangeable without tools

- Product Handling

- Suction attachment

- Load Capacity

- Varies depending on robot size

- Programming Options

- Multiple programmable uses

- Automation Level

- Fully automated processes

- Collaborative Use

- Space-saving application

- Application Flexibility

- Multiple application options

- Production Reliability

- High reliability

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Continuous

- Changeover time

- Quick, tool-free gripper exchange

- Cleaning method

- Manual

- Energy efficiency

- Space-saving design

- Space utilization

- Collaborative, minimal safety zone

- Flexibility

- Multiple application options and custom programs

- Reliability

- High, reduced manual intervention

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Task Suitability

- Handling, Feeding, Removing Trays, Dough Pieces

- Robot size

- Various sizes for different load capacities

- Gripper type

- Interchangeable, includes grippers and suction attachments

- Space requirement

- Space-saving design, collaborative use

- Footprint

- Compact, suitable for space-limited environments

- Material handling method

- Gripping and suction for trays and products

- Discharge method

- Automated loading and unloading

- Control panel type

- Touchscreen / Manual interface

- Gripper attachment

- Tool-free exchange

- Robot size options

- Various sizes based on load capacity

- Suction attachment

- For product handling

- Tool exchange

- Without tools

- Integration possibilities

- Compatible with multiple baking processes

- Automation levels

- Various programs can be stored