High-throughput tube transfer system for lab automation

Streamline laboratory workflows by automating high-throughput tube transfer, enhancing precision and consistency while significantly minimizing manual intervention and the risk of cross-contamination.

Automates Liquid Transfer and Sample Processing

The PurePrep TTR from LabTIE is a high-throughput tube transfer system designed to optimize liquid handling in biotechnology and clinical diagnostics labs. It features a dual-arm design capable of processing up to 320 samples per hour, utilizing air displacement for precise liquid transfer from tubes to deep well microtiter plates. This system is specifically engineered to handle varying tube sizes and includes automated de-capping and barcode scanning, ensuring efficient tracking and reducing manual labor. The PurePrep TTR is ideal for applications in nucleic acid handling and high-throughput screening, producing end-products like DNA extraction kits and RNA sequencing libraries. Its LIMS compatibility enhances workflow integration, while its automation capabilities eliminate the potential for contamination and reduce operator intervention. Designed with a focus on customization and versatility, it comes equipped with adjustable racks and robotic pipette tips, making it a vital tool in high-volume laboratories.

Benefits

- Increases sample processing efficiency, reducing hands-on time by automating liquid transfers.

- Minimizes contamination risk through seamless integration of automated de-capping and barcode scanning.

- Enhances operational flexibility with adjustable sample racks for various tube sizes.

- Ensures accurate and reliable sample tracking with its LIMS-compatible design.

- Supports uninterrupted workflow with the ability to resume runs after interruptions like power failures.

- Applications

- Drug discovery, Proteomics, Liquid transfer, Sample processing, Laboratory automation, Biotechnology labs, Genomics, High-throughput screening, Nucleic acid handling, Clinical diagnostics

- End products

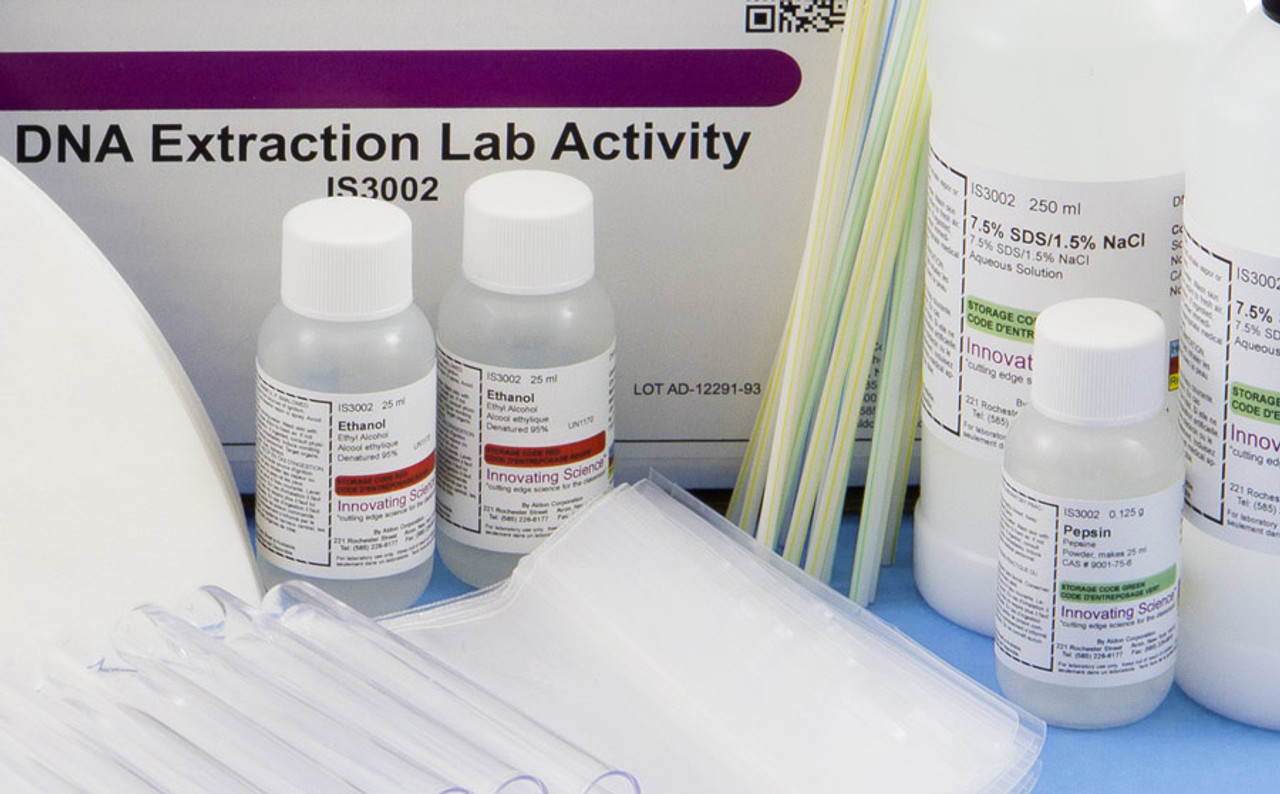

- High-throughput assay plates, Recombinant protein samples, Rna sequencing libraries, Dna extraction kits, Pharmacogenomics assays, Viral load test reagents, Diagnostic test kits

- Steps before

- Sample Collection, Transport, Labeling, Sample Preparation

- Steps after

- Analysis, Data Entry, Storage

- Input ingredients

- tubes, swabs, samples, PurePrep TL+ samples

- Output ingredients

- deep well microtiter plates, processed samples, disposed robotic pipette tips

- Market info

- Molgen is known for manufacturing customized engineered-to-order (ETO) equipment, specializing in tailored solutions for complex industrial needs. Their expertise lies in innovative engineering, delivering high-quality, precise, and reliable machinery that meets specific client requirements.

- Samples per hour

- 320

- Power Supply

- 400 VAC 3P+N+Pe 16A CEE form, 16A

- Width

- 170 cm

- Depth

- 107 cm

- Height

- 203 cm

- Weight

- 550 kg

- Automation

- LIMS-compatible

- Accuracy

- High accuracy via air displacement

- Volume control

- Unlimited

- Used Pipette Tips Disposal

- Automatic

- Working mechanism

- Air displacement pipetting

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous processing

- Integrated steps

- Tube de-capping, Barcode scanning, Sample tracking

- Sample tracking

- LIMS-compatible with barcode scanning

- Cross-contamination control

- Swirling pipette motion

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CE marking

- Yes

- FDA compliance

- Yes

- LIMS compatibility

- Yes

- Machine footprint

- Width

- Weight

- 550 kg

- Sample capacity

- 320 samples per hour

- Adjustable sample rack

- Yes, T-Rack with adjustable height

- Tube compatibility

- Various tube sizes

- Pipette Tips

- Robotic Disposable

- Integrated Barcode Scanner

- Yes

- T-Rack Adjustability

- Adjustable height for various tube sizes

- Processing Capacity

- Up to 320 samples per hour

- Pipetting Arm Design

- Dual-arm with swirl motion

- Tube Size Compatibility

- Customizable for various tube sizes

- Air Displacement Pipetting

- Enabled