Industrial shuttle for transporting heavy components

Optimize your production line with a shuttle that handles heavy vehicle components swiftly, enhancing workflow and minimizing downtime with high-speed, automated transport solutions.

Transports and Positions Automotive Components Rapidly

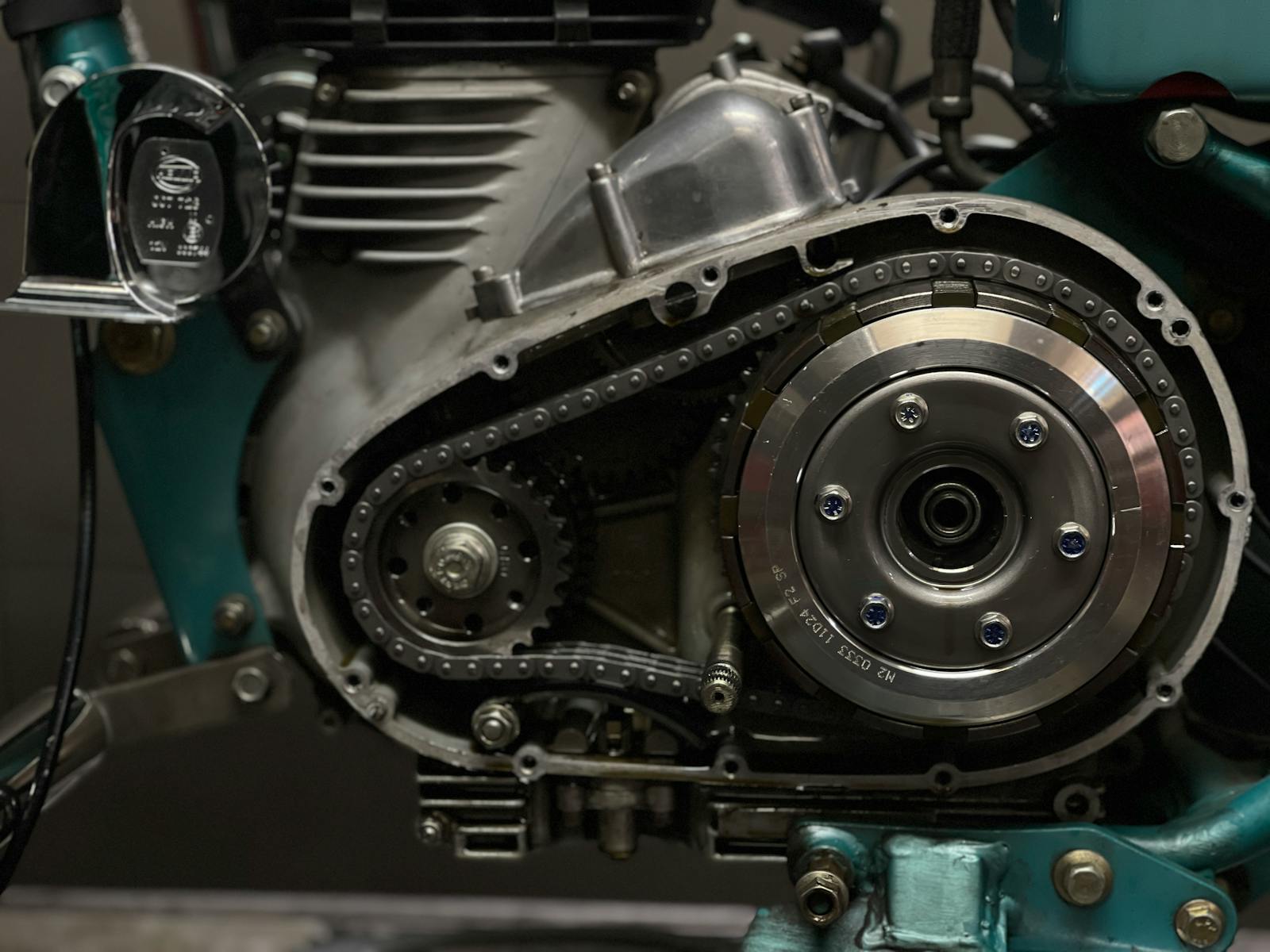

The KS Lift-and-Carry Shuttle from KUKA is engineered to optimize the transportation of automotive subassemblies and vehicle components. Designed with automotive manufacturers in mind, this shuttle system efficiently lifts, transports, and lowers chassis frames, car doors, engine blocks, and more, streamlining your production process. The modular system accommodates between four and ten stations and uses a single motor for cost-effective operation. With optimized motion profiles, customizable station spacing, and rapid transport speeds, the shuttle can swiftly integrate into high-speed, automated operations. Its robust design ensures longevity and minimal maintenance, making it a reliable addition to any automotive production line.

Benefits

- Increases production efficiency by swiftly moving components between stations.

- Minimizes operational costs with a single-motor design for lifting and lowering.

- Customizable station spacing adapts to specific production line requirements.

- Enhances line productivity with high-speed transport and rapid cycle times.

- Lowers maintenance needs and downtime with a straightforward, robust construction.

- Applications

- Vehicle components, Automotive subassemblies, Car bodies

- End products

- Body panels, Engine blocks, Car doors, Vehicle chassis, Wheel assemblies, Transmission cases, Chassis frames, Dashboard assemblies

- Steps before

- Body shop preparation, Subassembly arrangement, Component staging

- Steps after

- Assembly integration, Quality inspection, Final assembly

- Input ingredients

- individual subassemblies, entire car bodies, components

- Output ingredients

- subassemblies, car bodies, components

- Market info

- KUKA is renowned for its expertise in industrial robotics and automation solutions, specializing in providing advanced robotic systems for manufacturing, automotive, electronics, and logistics industries, with a reputation for innovation and quality in engineered-to-order equipment.

- Payload Capacity

- 500 kg

- Speed

- 3–6 seconds per traverse

- Lifting Time

- 2 seconds

- Lowering Time

- 2 seconds

- Station Variants

- 4 to 10 stations

- Operating Costs

- Low (single motor for lifting and lowering)

- Drive System

- Modular horizontal drive with one or two motors

- Design

- Compact, standardized components

- Motion Profiles

- Individually optimized

- Working mechanism

- Lift-and-Carry

- Integration steps

- 4 Key Steps (Pick, Transport, Lower, Return)

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- Automated

- Changeover time

- Minimal due to standardized components

- Energy efficiency

- Low, due to single motor usage

- Transport speed

- High traversing velocity

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Compact design for minimal obstructions

- Machine footprint

- Modular structure

- Discharge method

- Horizontal transport

- Lifting mechanism

- Lifting movement

- Payload capacity

- 500 kg

- Modular structure

- 4 to 10 stations

- Station spacing

- Variable according to customer's requirement

- Drive system

- One or two motors