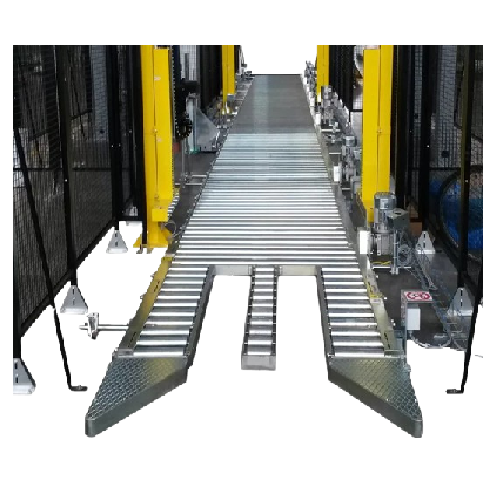

Pallet handling system

Streamline your production line with advanced pallet handling solutions that efficiently automate conveying, rotating, and stacking processes, ensuring seamless integration and enhanced operational flow.

Conveys, Rotates, Transfers, and Stacks Pallets

Designed by Robopac, the Pallet Handling Systems offer robust solutions for efficient conveying and automated pallet management. These systems feature motorized and chain conveyors, 90° rotating tables, and pallet stackers to streamline movement and storage of products like bottled water, canned goods, and paper rolls. Efficiently handling up to high-speed needs, the equipment seamlessly integrates into existing lines with PLC control for automation, and is customizable to suit specific packaging operations in the beverage, food, and paper industries. With low-energy consumption and options for corrosion-resistant materials, these systems are built for durability and compliance with industry standards, facilitating easy maintenance via optional CIP systems for hygiene-critical environments.

Benefits

- Enhances operational efficiency with automated pallet positioning and transfer.

- Supports high-speed production lines to increase output without manual intervention.

- Lowers energy consumption through optimized conveyor systems.

- Facilitates seamless integration into existing production setups with flexible customization.

- Complies with industry standards, ensuring safe use in various packaging environments.

- Applications

- Food, Personal care, Beverage, Tissue, Lubricants, Paper, Corrugated, Home

- End products

- Canned soups, Bottled water, Liquid detergents, Engine oil containers, Toilet paper rolls, Paper towels, Carbonated drinks, Packaged snacks, Shampoo bottles, Corrugated cardboard boxes

- Steps before

- Loading, Palletizing, Packing, Depalletizing

- Steps after

- Stretch Wrapping, Banding, Internal Logistics, Distribution

- Input ingredients

- palletized loads, wooden pallets, pallet feet, empty pallets

- Output ingredients

- reoriented pallets, stacked pallets, aligned pallets, elevated pallets

- Market info

- OCME, part of Aetna Group Italy, is renowned for manufacturing innovative, high-quality packaging and material handling solutions, including filling, palletizing, and conveying systems, with a strong reputation for reliability and technological advancement in industrial sectors.

- Motorized or Idle Roller Conveyors

- TPM version

- Chain Conveyors

- For palletized loads with crosswise slats

- Low Profile Conveyors

- Floor installation

- 90° Rotating Tables

- Roller or chain conveyor version

- 90° Rollers/Chains Transfer

- Modifies leading front

- Pallet Stacker

- Automatic overlap

- Empty Pallet Magazine

- Motorized

- Pallet Elevators

- Height changing capability

- Pallet Aligner Device

- Pneumatic

- Conveyor Type

- Motorized/Idle Roller, Chain, Low Profile

- Rotation Capability

- 90° Rotating Table

- Pallet Transfer Method

- 90° Rollers/Chains Transfer

- Pallet Overlap System

- Automatic Pallet Stacker

- Pallet Alignment

- Pneumatic Aligner Device

- Empty Pallet Management

- Motorized Empty Pallet Magazine

- Pallet Handling Customization

- Automation for Custom Requirements

- Height Adjustment

- Pallet Elevators

- Material Flow Direction

- Leading Front Adjustment

- Labor Efficiency

- Visual Indicators with TPM Version

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customized based on requirements

- Handling system type

- Motorized/idle roller conveyors, chain conveyors

- Installation type

- Floor-mounted

- Loading/unloading method

- Transpallet compatible

- Roller Conveyor Type

- Motorized / Idle

- Chain Conveyor Application

- Special Applications

- Low Profile Conveyor Installation

- Floor Fitting

- 90° Rotating Table Conveyor Type

- Roller / Chain

- Pallet Elevator Loading

- Surface Shaped for Transpallet

- Visual Indicators

- TPM Version