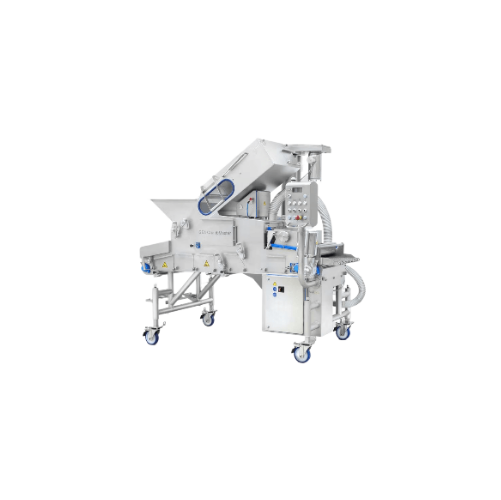

Crumb coating system for meat and poultry

Achieve uniform breading with minimal crumb loss and dust emission, enhancing product quality for high-speed operations and ensuring a cleaner work environment.

Applies and Maintains Consistent Crumb Coating

The GEA CrumbMaster Gen 2, engineered by GEA, revolutionizes crumb coating in food production lines. Specially designed to minimize crumb breakage and dust, it features an enclosed system that reduces dust by up to 90%, creating a cleaner work environment. Capable of handling diverse breadcrumbs, from fine to premium specialties, it ensures consistent application on products like breaded chicken nuggets and plant-based burgers. With a patented crumb divider, you can adjust the top and bottom crumb layers independently for precise coating. Its flexible design supports fast product changeovers with belt speeds up to 30m/min and widths from 400mm to 1000mm, catering to continuous, high-speed operations. The machine meets stringent global hygiene standards, featuring stainless steel components and a user-friendly cleaning system, ensuring minimal downtime and maintenance effort. Integrate effortlessly with existing lines, enhancing productivity while maintaining high-quality output.

Benefits

- Ensures consistent product coating with reduced crumb waste, enhancing final product quality.

- Creates a cleaner, safer work environment by reducing dust emissions by up to 90%.

- Facilitates quick product changeovers, minimizing production downtime.

- Supports diverse crumb types, offering flexibility for various product styles.

- Meets stringent hygiene standards, simplifying cleaning and maintenance tasks.

- Applications

- Seafood, Snacks, Meat-replacement products, Vegetables, Poultry, Red meat

- End products

- Soy-based chicken strips, Breaded pork cutlets, Cornflake-coated chicken, Plant-based burgers, Vegetable tempura, Breaded calamari rings, Onion rings, Breaded chicken nuggets, Fish sticks, Shrimp popcorn

- Steps before

- Pre-dusting, Battering

- Steps after

- Frying, Baking, Freezing, Packaging

- Input ingredients

- red meat, poultry, seafood, vegetables, meat-replacement products, breadcrumbs, fine crumbs, J-crumbs, premium crumbs, specialty breaders

- Output ingredients

- breaded red meat, breaded poultry, breaded seafood, breaded vegetables, breaded meat-replacement products, crumb-coated products, cornflake-coated products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Belt width

- 400/600/1000 mm

- Max. belt load

- 10 kg/lin m, 15 kg/lin m, 25 kg/lin m

- Min. product size

- 16 mm

- Max. free product space

- 70 mm

- Min. crumb volume

- 60 liter, 90 liter, 150 liter

- In-feed height

- 1060 ± 80 mm

- Out-feed height

- 1060 ± 80 mm

- Belt speed min/max

- 3 to 30 m/min

- Wire belt gap

- 2, 35 - 12, 7 mm (gap 10, 35 mm)

- Dimensions L x W x H

- 2635 x 1440 x 2315 mm, 2620 x 1140 x 2315 mm, 2620 x 1790 x 2315 mm

- Machine weight

- 580 kg, 690 kg, 1030 kg

- Working mechanism

- Crumb coating

- Integrated steps

- Crumb recirculation with blow-off control

- Cleaning method

- Easy access, fold-away panels, self-draining

- Dust reduction

- Enclosed design, up to 90% dust elimination

- Batch vs. continuous operation

- Inline continuous

- Changeover time

- Fast, in-line product changeover

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Cleanability

- Easy-to-clean design

- Density/particle size

- Handles fine to J-crumbs

- Belt width

- 400mm, 600mm, 1000mm

- In-feed height

- 1060 ± 80 mm

- Out-feed height

- 1060 ± 80 mm

- Dimensions (L x W x H)

- 2635 x 1440 x 2315 mm (varies with configuration)

- Machine weight

- 580 kg, 690 kg, 1030 kg

- Belt load capacity

- 10 kg/lin m, 15 kg/lin m, 25 kg/lin m

- Crumb size adjustment

- Independent top and bottom

- Belt width

- 400mm, 600mm, 1000mm

- Pressure roller adjustment

- Adjustable pressure

- Crumb composition adjustment

- Different top and bottom

- Crumb divider plates

- Exchangeable

- Tool-less exterior adjustment

- Available

- Cleaning accessibility

- Easy access fold-away panels

- Product changeover

- Fast, in-line