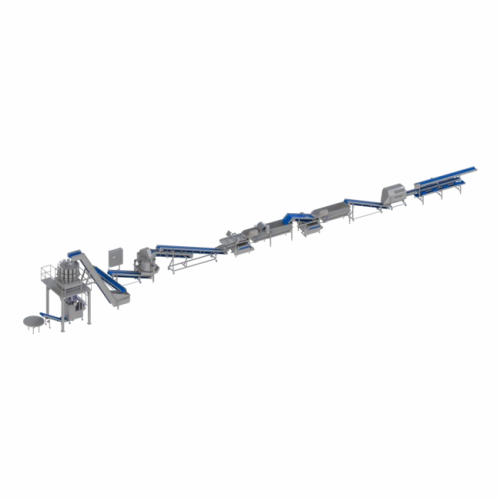

Lettuce processing and packaging line

Maximize throughput with seamless integration of trimming, cutting, washing, and packaging processes. Tailored for high-capacity salad and vegetable handling, this advanced line ensures consistent product quality and efficiency, reducing manual labor while enhancing production flow for leafy greens, fruits, and vegetables.

Processes and Packages Leafy Greens and Vegetables

The GS 20 belt cutting machine, part of KRONEN’s automated processing line, excels in high-volume handling of salads and vegetables. It integrates seamlessly with GEWA 4000 PLUS and GEWA 5000 PLUS washing systems to deliver precise cutting and thorough washing for products like pre-packaged salad mixes and ready-to-eat vegetable medleys. Thanks to its continuous throughput of up to 2,000 kg/h, this line efficiently manages various vegetables and fruits while preserving their quality. Equipped with a flexible conveyor system and the K650 drying unit, it supports both automatic and semi-automatic operations. The line’s hygienic design facilitates easy cleaning, ensuring minimal downtime. Additionally, customization options allow adaptation to specific production needs, making it suitable for diverse food processing environments.

Benefits

- Enhances production capacity with up to 2,000 kg/h throughput.

- Minimizes labor costs with semi-automatic and continuous operation.

- Ensures high product quality through gentle processing techniques.

- Simplifies cleaning processes with its hygienic and accessible design.

- Offers flexible integration and customization for diverse product lines.

- Applications

- Mixed lettuce, Salads, Rocket, Arugula, Fruits, Cabbage, Herbs, Vegetables, Baby leaf lettuce, Leafy vegetables, Carrots

- End products

- Ready-to-eat vegetable medleys, Prepared mixed lettuce bags, Diced carrots, Fruit salad mixes, Sliced fruits, Bagged arugula, Packaged baby leaf lettuce, Shredded cabbage, Chopped herbs, Pre-packaged salad mixes

- Steps before

- Harvesting, Inspection, Sorting

- Steps after

- Transport, Storage, Distribution

- Input ingredients

- lettuce, cabbage, carrots, whole lettuce leaves, mixed lettuce, arugula, rocket, baby leaf lettuce, fruits, herbs

- Output ingredients

- cut lettuce, cut cabbage, cut carrots, trimmed or segmented fruits, dried vegetables, packaged lettuce, packaged vegetables, packaged fruits, mixed lettuce

- Market info

- KRONEN is known for manufacturing industrial food processing equipment, specializing in washing, cutting, peeling, and packaging machinery, recognized for innovation, high quality, and efficiency in automated food processing solutions.

- Capacity

- up to 2, 500 kg/h

- Capacity - Iceberg Lettuce

- up to 1, 500 kg/h

- Capacity - Cabbage and Carrots

- up to 2, 000 kg/h

- Capacity - Arugula/Rocket and Baby Leaf Lettuce

- up to 350–400 kg/h

- Automation

- Automatic

- Loading Type

- Automatic / Semi-automatic

- Number of Personnel at Trimming Table

- 8 People

- Bag Width

- up to 350 mm

- Alternative Bag Width

- up to 500 mm with FLEX XL

- Automation level

- Semi-automatic / Fully automatic

- Batch vs. Continuous Operation

- Continuous

- Working Mechanism

- Automatic system for cutting, washing, drying, weighing, and packaging

- CIP/SIP

- CIP / Manual cleanability

- Cleaning Method

- Optimized for hygiene, ease of access for cleaning

- Energy Efficiency

- Optimized for high capacity production

- Integrated Steps

- Trimming, cutting, washing, drying, weighing, and packaging

- Changeover Time

- Minimal due to quick knife and component changes

- Handling Capacity

- Up to 2, 000 kg/h

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container Size and Shape

- Up to 350 mm width

- Container Type

- Lettuce and vegetables

- Container type

- Lettuce, vegetables, herbs

- Filling purpose

- Packaging of lettuce/vegetables

- Capacity

- up to 2, 000 kg/h

- Trimming table size

- 8 people

- Belt cutting machine type

- GS 20

- Conveyor belt type

- PLUS inclined conveyor belt

- Washing machine type

- GEWA 4000 PLUS / GEWA 5000 PLUS

- Drying system type

- K650 drying system

- Packaging machine type

- FLEX L packaging machine

- Bag width

- up to 350 mm

- Centrifuge diameter

- 650 mm

- Control panel type

- HMI touch screen

- Integration possibilities

- SMART line communication-enabled

- Inclined conveyor belt design

- Flexible design with/without cleats, variable dimensions

- Trimming table capacity

- 8 or 10-person configuration

- Washing machine output

- Vibration or dipping belt outfeed

- Packaging bag width

- Up to 350 mm or 500 mm with FLEX XL

- Packaging machine gas flushing

- MAP (Modified Atmosphere Packaging) option