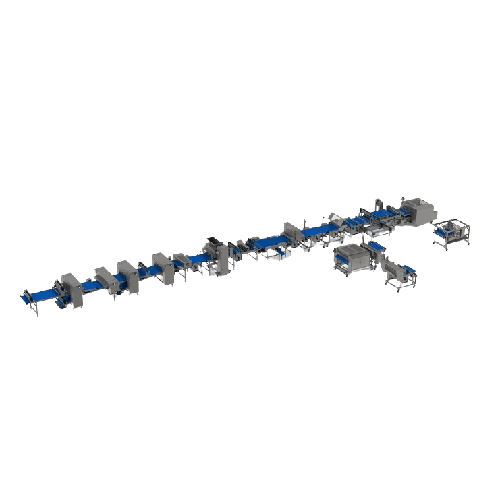

Universal pastry production line for industrial baking

Optimize your bakery operations with a versatile line capable of producing a wide range of pastries, from Danish to cheese biscuits, enhancing efficiency through automated shaping, depositing, and decorating processes.

Automates Shaping and Forming of Pastry Products

Rademaker’s Industrial Universal Pastry Make-Up Line is a sophisticated solution tailored for high-speed automation in pastry production, ideal for industrial and midsize bakeries. This equipment excels in precision forming and shaping of laminated dough into a variety of pastries, such as Danish pastries, croissants, and cookie snacks. Featuring a modular design, it accommodates continuous production processes with integrated depositing, laminating, cutting, decorating, and proofing steps.

The line supports multiple dough types with flexible shaping options, enhancing its versatility across applications like bread, flatbreads, pizza, and more. Capable of handling mid to industrial-scale volumes, it optimizes throughput while maintaining superior product quality and weight consistency. Its automated tool assistant simplifies operations, ensuring quick changeovers and minimal downtime. Engineered for hygiene, it complies with GMA and EHEDG standards, featuring FDA-approved materials for easy, safe cleaning.

Designed for seamless integration, the line is PLC-controlled with options for remote monitoring, enhancing operational efficiency and energy savings. As a customizable solution, it supports various working widths and tool configurations, ensuring it meets specific production requirements while providing reliable support and maintenance options.

Benefits

- Enhances production efficiency with automated high-speed processes and rapid changeovers.

- Reduces labor costs through user-friendly tool assistant and intuitive controls.

- Ensures superior hygiene with GMA and EHEDG-compliant design and FDA-approved materials.

- Optimizes energy usage, contributing to lower operational costs.

- Offers exceptional versatility, accommodating a wide range of pastry products and production scales.

- Applications

- Pie, Snacks, Bread, Flatbreads, Pizza, Croissants, Quiche, Pastries

- End products

- Palmier, Cookie snacks, Cheese biscuits, Maple pecan, Coffee bread, Snack, Apple turnover, Danish pastry, Twisted swirl, Twisted sticks, Swirl, Pain-au-choc

- Steps before

- Dough preparation, Dough mixing, Dough fermentation, Lamination

- Steps after

- Proofing, Freezing, Baking, Tray loading, Cooling

- Input ingredients

- laminated dough, mono-production dough, multi-production dough, egg yolk, water, fruit, cheese

- Output ingredients

- twisted swirl, Danish pastry, coffee bread, pain-au-choc, apple turnover, snack swirl, cookie snacks, palmier, twisted sticks, cheese biscuits, maple pecan

- Market info

- Rademaker is known for its expertise in manufacturing industrial bakery equipment, offering engineered-to-order solutions. They have a strong reputation for innovative, high-quality machines designed for efficiency and reliability in food production.

- Working widths

- 600 mm | 800 mm | 1, 000 mm | 1, 200 mm | 1, 400 mm | 1, 600 mm

- Operating costs

- Extremely low

- Capacity

- Midsized to industrial volumes

- Automation

- Automatic operations with fast and easy change-over

- Dough types

- Variety of dough types including laminated

- Product types

- Wide variety (Twisted swirl, Danish pastry, Coffee bread, etc.)

- Material usage

- Flour consumption reduced to minimum

- Product quality

- Highest product quality

- Shaping methods

- Different shaping methods available

- Change-over

- Quick and easy change-over

- Design

- Hygienic and modular design

- Hygienic standards

- Compliant with GMA and EHEDG recommendations

- Machine surface

- Excellent finishing

- Frame design

- Rounded frames with minimized hinges, bolts

- Materials

- FDA approved materials

- Accessibility

- Improved accessibility for cleaning and inspection

- Cleaning

- Easy cleaning without reducing safety

- Automation level

- Fully automated

- Changeover time

- Quick and easy

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- Low operating costs

- Working Widths

- 600 mm | 800 mm | 1, 000 mm | 1, 200 mm | 1, 400 mm | 1, 600 mm

- Footprint

- Modular Design

- Construction Material

- FDA Approved Materials

- Design Features

- Open Design, Rounded Frames

- Surface Finish

- Excellent Machine Surface Finishing

- Discharge Method

- Automatic Transfer to Proofer, Freezer, or Baking Trays

- Control Panel Type

- Operator Panel with Tool Assistant

- Working Widths

- 600 mm | 800 mm | 1, 000 mm | 1, 200 mm | 1, 400 mm | 1, 600 mm