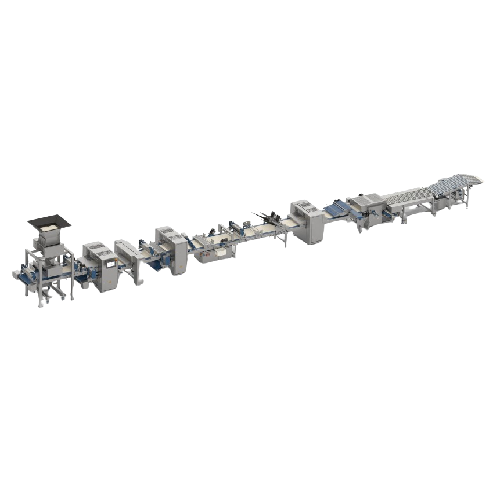

Donut production line for various shapes and sizes

Optimize your bakery’s output with precision-engineered dough processing, allowing for effortless production of a wide array of donut shapes and sizes, while maintaining consistent quality. Perfect for operations aiming to enhance efficiency and product variety.

Produces Diverse Donut Varieties Efficiently

The Radini Donut Production Line from Rademaker is tailored for industrial bakeries and food processing companies seeking precision and consistency in deep-fried goods. This line excels in producing a variety of donut shapes, including ring and heart-shaped products, thanks to its stress-free sheeting and shaping capabilities. Its fully automatic and continuous operation allows for a capacity of up to 1,200 kg of dough per hour, translating to approximately 13,900 ring donuts hourly.

Utilizing a sequence of sheeting, shaping, cutting, and rolling processes, the equipment offers flawless dough handling while quick-change tooling supports versatile shape alterations. Lightweight and ergonomic, the tooling ensures ease during changeovers. A reliable conveying system spreads and supports products for consistent quality and ready proofing.

Designed for semi-industrial scales, the Radini Line integrates seamlessly into existing bakery setups. It features intuitive controls and recipe-driven automation for seamless operation, guaranteeing uniform dough quality. Constructed with durable materials, it is optimized for energy efficiency and easy maintenance, making it an invaluable asset for high-volume donut production.

Benefits

- Enhances production efficiency with consistent, high-capacity output.

- Facilitates quick flavor and shape changes, minimizing downtime.

- Ensures consistent product quality through automated recipe control.

- Reduces manual labor with ergonomic, easy-change tooling design.

- Integrates effortlessly with semi-industrial bakery operations.

- Applications

- Buns, Bread, Croissants, Donuts, Pastries, Deep-fried products

- End products

- Long john's, Snowflake clusters, Square donuts, Heart-shaped deep-fried products, Ring donuts, Cinnamon rolls

- Steps before

- Mixing ingredients, Dough preparation

- Steps after

- Proofing, Deep-frying, Cooling, Packing

- Input ingredients

- dough, pre-sheeter raw dough, rework dough

- Output ingredients

- ring donuts, heart shaped deep-fried products, cinnamon rolls, square donuts, snowflake clusters, Long John's, custom designed shapes

- Market info

- Rademaker is known for its expertise in manufacturing industrial bakery equipment, offering engineered-to-order solutions. They have a strong reputation for innovative, high-quality machines designed for efficiency and reliability in food production.

- Working width

- 800 mm

- Capacity

- up to 1, 200 kg dough per hour

- Production capacity

- Circa 13, 900 ring donuts per hour

- Production capacity

- Circa 14, 000 heart shaped products per hour

- Automation

- Automatic recipe-driven in- and outfeed control

- Tool exchange

- Quick exchange setup

- Working mechanism

- Pre-sheeter to continuous dough sheet

- Integrated steps

- Sheeting, shaping, spreading, processing

- Automation level

- Automatic recipe driven in- and outfeed control

- Changeover time

- Quick exchange setup for tools

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Easy tool mounting/dismounting

- Capacity

- Up to 1, 200 kg dough per hour

- Cleanability

- Easy to clean design

- Working width

- 800 mm

- Machine throughput

- Circa 13, 900 ring donuts per hour

- Machine throughput

- Circa 14, 000 heart shaped products per hour

- Feed method

- Automatic in- and outfeed control

- Tooling changeover

- Quick exchange setup

- Control panel

- Intuitive controls with recipe memory

- Dough type compatibility

- Laminated and non-laminated dough

- Control panel type

- Intuitive controls

- Integration capabilities

- Automatic recipe-driven in- and outfeed control

- Product changeover

- Quick and easy exchange setup

- Tooling adaptability

- Mounting and dismounting ease