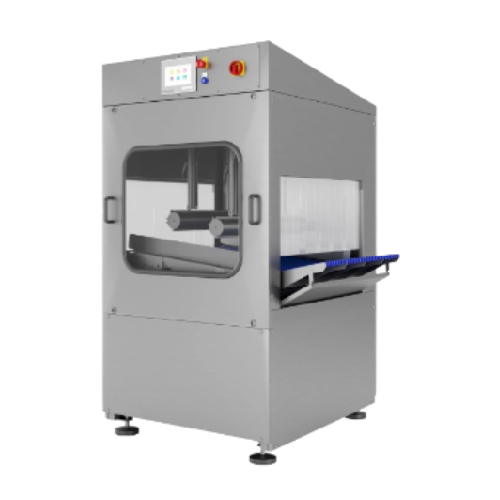

Stainless steel drying tunnel for packaging lines

Optimize your packaging line efficiency by ensuring products are thoroughly dried post-shrink wrapping, ready for seamless labeling and marking.

Dries Packaged Items Before Next Production Stage

The Drier 800 from Saccardo is an essential component of industrial packaging lines, specifically designed for the food, beverage, and packaging industries. This drying tunnel is strategically placed after shrink tunnels to remove moisture from products like snack bags, bottled beverages, and pre-packaged meals, ensuring they are label-ready. Featuring a robust stainless steel structure, it is powered by a single blower motor that supplies three air blades, enhancing drying efficiency. The integrated PLC touch screen control panel allows precise adjustments to the conveyor belt speed, accommodating varying product sizes up to 750 mm in length and 350 mm in height. Its stainless steel wide mesh conveyor ensures durability and smooth product handling. With a power consumption of approximately 8 kW and operation at 400V – 50Hz, the Drier 800 offers reliable performance while remaining energy efficient. This equipment is designed for easy sanitation and maintenance, contributing to uninterrupted production flow and adhering to stringent hygiene standards.

Benefits

- Enhances product quality by ensuring complete moisture removal, readying items for subsequent processes like labeling.

- Minimizes energy costs with a power-efficient design consuming approximately 8 kW.

- Reduces manual intervention and labor costs with a PLC-controlled touch screen interface.

- Maintains high throughput with continuous automatic operation, increasing productivity.

- Ensures easy cleaning and hygiene maintenance with its stainless steel construction.

- Applications

- Packaged beverages, Consumer goods, Packaging industry, Marking applications, Labeling applications, Packaged foods

- End products

- Snack bags, Bottled beverages, Printed packaging materials, Shrink-wrapped items, Label-ready jars, Pre-packaged meals, Canned goods

- Steps before

- Shrink Tunneling

- Steps after

- Labelling, Marking, Packaging

- Input ingredients

- products after shrink tunnel

- Output ingredients

- dried products

- Market info

- Starvac Systems is known for manufacturing high-quality vacuum systems and engineered solutions tailored to various industrial applications. They are reputed for their innovation, reliability, and technical expertise in delivering custom-engineered vacuum equipment.

- Overall dimensions

- 1482 x 1355 x 1910 (H) mm

- Max product length

- 750 mm

- Max product height

- 350 mm

- Power consumption

- ≈ 8 kw

- Voltage

- 400V - 50Hz

- Automation

- PLC-controlled

- Belt material

- Stainless steel mesh

- Conveyor belt speed

- Adjustable

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Easy sanitation and maintenance

- Conveyor speed adjustment

- Adjustable

- System integration

- Works with shrink tunnel

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 1482 x 1355 x 1910 mm

- Max product length

- 750 mm

- Max product height

- 350 mm

- Structure material

- Stainless steel

- Conveyor belt material

- Stainless steel with wide mesh

- Control panel

- Touch screen

- Conveyor belt speed

- Adjustable

- Control panel type

- Touch screen

- Integration possibilities

- PLC-controlled

- Adjustable conveyor belt speed

- Yes