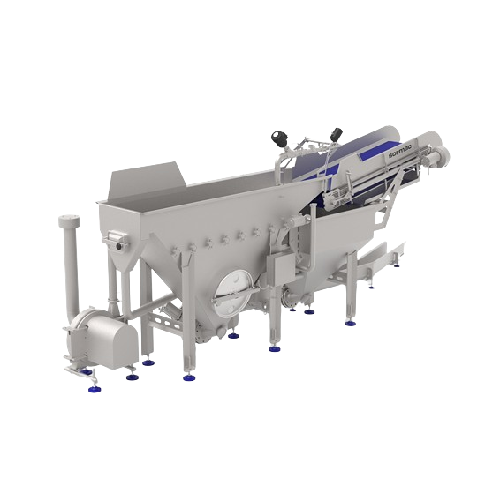

Leafy vegetable desander

Efficiently cleanse leafy vegetables by submerging and loosening sand, stones, and granules, ensuring your produce is free from impurities and ready for packaging.

Removes Sand and Stones from Leafy Vegetables

The Leafy Vegetable Desander BO from Sormac is expertly engineered to tackle the challenges of sand and stone contamination in leafy vegetable production. Utilizing a conical washer design, this system uses an integrated air-injection process, submerging produce to create turbulence that dislodges contaminants. The particles are then transported into a collection tank via spirals, ensuring efficient cleaning. With a capacity of up to 1,000 kg per hour, it is ideal for processing lamb’s lettuce, pre-washed salad bags, and other fresh produce. The outfeed belt, equipped with a spray bar, guarantees a final rinse, preparing your produce for subsequent processing stages. The large manhole opening facilitates easy maintenance and cleaning. Available options include longer outfeed belts and stainless steel motors, allowing customization for specific production requirements. This desander seamlessly integrates with existing lines, working well with washing flumes, centrifuges, and air drying tunnels to optimize processing efficiency in food, agricultural, and horticultural industries.

Benefits

- Ensures high purity produce by effectively removing sand and stones, reducing waste.

- Streamlines processes with continuous, automated operation, enhancing productivity.

- Facilitates easy maintenance with a large manhole opening, minimizing downtime.

- Customizable options allow seamless integration into various production lines.

- Enhances product quality by providing a final rinse, ensuring consistent cleanliness.

- Applications

- Salads, Leafy vegetables, Lamb’s lettuce

- End products

- Baby spinach containers, Ready-to-eat salad kits, Arugula clamshells, Packaged lamb’s lettuce, Pre-washed mixed salad bags, Spring mix salad, Mesclun salad packs, Kale salad blends, Organic spinach bags, Chopped salad mix

- Steps before

- Pre-washing, Sorting

- Steps after

- First washing stage, Dewatering, Air drying, Packing

- Input ingredients

- lamb's lettuce, leafy vegetables, small stones, clay granules, sand particles

- Output ingredients

- clean leafy vegetables, washed lamb's lettuce, separated sand, separated stones

- Market info

- Sormac is known for its expertise in manufacturing high-quality vegetable processing equipment, particularly peeling, washing, and slicing machines, with a strong reputation for innovation, reliability, and customer-focused solutions in the food processing industry.

- Capacity

- 1, 000 kg per hour (2, 200 lbs)

- Automation

- Air-injection system

- Cleaning method

- Large manhole opening for easy maintenance and cleaning

- Outfeed belt type

- Equipped with spray bar for rinsing

- Working mechanism

- Conveyor belt with air-injection system

- Integrated steps

- Submerging, turbulence, rinsing

- CIP/SIP

- Large manhole for manual cleaning

- Automation level

- Automatic with manual maintenance access

- Batch vs. continuous operation

- Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Sand particle size

- Small

- Produce type

- Lamb’s lettuce

- Footprint

- Compact

- Tank shape

- Conical base

- Feed method

- Belt transport

- Discharge method

- Outfeed conveyor

- Manhole opening

- Large

- Construction material

- Stainless steel

- Maintenance access

- Manhole opening

- Outfeed belt length

- Standard / Longer

- Motor type

- Stainless steel / Standard

- Spray bar type

- Standard / Customizable

- Waste screw conveyors

- Standard / Stainless steel motor