Lye application system for pretzel production

Achieve precise lye application for pretzel pastries with high-speed capabilities, ensuring consistent surface treatment while maintaining production efficiency and quality.

Applies Lye and Sprinkles for Pretzel Production

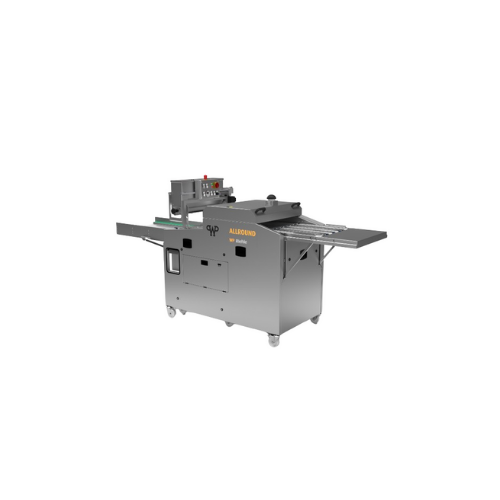

The ALLROUND Lye Application Machine from WP Riehle is engineered for bakeries and food production facilities focused on high-speed pretzel and lye-treated pastry production. This machine features a patented lye shower and double lye curtain to ensure precise and uniform lye distribution, even at high throughput rates. With a capacity to process up to 400 trays per hour, it integrates seamlessly into bakery lines for continuous operations.

The ALLROUND is equipped with an extendible 180-litre lye tank and adjustable heating system, guaranteeing consistent temperature and optimal lye application. Optional features, such as an interchangeable salter and unloading belt, offer flexibility in product changeovers and maintain clean baking trays, enhancing production efficiency.

Designed for ease of use, the machine includes advanced controls such as an adjustable throughput speed and a lye level sensor that signals when replenishment is needed. Its space-saving design allows for infeed and outfeed trays to fold down after use. Built with robust materials, the equipment is ideal for the demands of large-scale bakery and snack production environments, ensuring reliable operation and high-quality end products like pretzels, lye rolls, and Laugenstange.

Benefits

- Enhances production speed with the ability to process up to 400 trays per hour.

- Ensures consistent product quality with precise lye distribution and adjustable heating.

- Increases operational flexibility with interchangeable salters and unloading options.

- Saves space and facilitates convenient operation with foldable infeed and outfeed trays.

- Maintains efficient operations through real-time monitoring with a lye level sensor.

- Applications

- Baked goods, Pretzels, Lye-treated pastries

- End products

- Laugenstange, Croissants, Lye rolls, Laugenkonfekt

- Steps before

- Dough Preparation, Pretzel Shaping

- Steps after

- Baking, Cooling, Packaging

- Input ingredients

- pretzel dough, lye solution, sprinkling materials

- Output ingredients

- lye-coated pretzels, lye rolls, Laugenstange, croissant, Laugenkonfekt

- Market info

- Capacity

- 1500-4000 pieces daily

- Lye Tank Capacity

- 180 litres

- Throughput Speed

- Adjustable

- Hourly Tray Handling

- Up to 400 trays

- Automation

- Includes lye level sensor

- Temperature Control

- Adjustable heating

- Dropping Height

- Reduced in 2020 version

- Lye Application

- Patented lye shower and double lye curtain

- Working mechanism

- Patented lye shower and double lye curtain

- Integrated steps

- Lye application, salting, unloading

- Automation level

- Automatic with adjustable throughput speed

- Batch vs. continuous operation

- Continuous

- Changeover time

- Quick change with interchangeable containers

- Energy efficiency

- Adjustable heating to maintain lye temperature

- Cleaning method

- Manual foldable trays for space saving

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Compact

- Tank Size

- 180 L

- Tank Shape

- Closed leach tank

- Feed/Discharge Method

- Adjustable speed with unloading belt

- Extendible Tank

- Yes

- Control Panel Type

- Adjustable settings for speed and lye level

- Lye tank capacity

- 180-litre

- Lye shower type

- Patented double lye curtain

- Speed adjustment

- Adjustable throughput speed

- Optional salter

- Interchangeable containers

- Optional unloading belt

- Reduced drop height

- Heating adjustment

- Adjustable heating for stable lye temperature

- Sensor type

- Lye level sensor

- Tray management

- Foldable infeed and outfeed trays

- Speedy operation

- Separate control for infeed conveyor