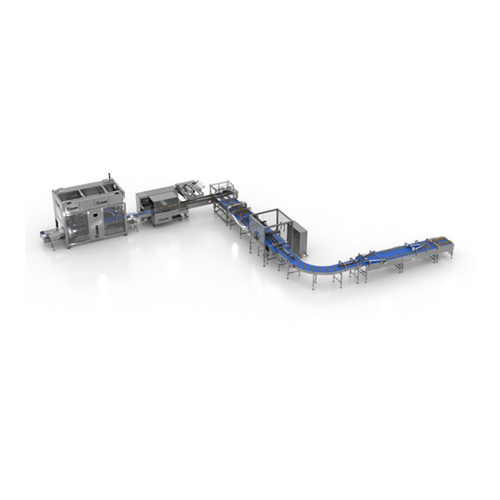

Automated packaging and case packing for soft bread & buns

Ensure consistent and high-speed packaging for your bakery goods with our solution that streamlines the packing, wrapping, and case packing process for soft bread and buns.

Wraps and Packs Soft Breads and Buns

The ULMA Flow Pack Machine is tailored for soft bread and bun packaging, delivering high-speed, fully automated performance. Utilizing a chicane system for product alignment and a double multiplier for distribution, this equipment ensures seamless operation from spiral cooler feed to horizontal wrapping. Ideal for hot dog, hamburger, and brioche buns, it supports MAP with aroma dispensing for optimal product freshness. Capable of integrating with upstream and downstream processes, it features intuitive case packing cells for flexible stacking patterns, all managed via a user-friendly HMI. This robust machine can achieve demanding production rates with single or double handler options, effectively meeting the needs of bakery producers and food manufacturers.

Benefits

- Enhances production efficiency by simplifying packing and wrapping processes for soft bread and buns.

- Lowers labor costs with intuitive, operator-friendly HMI for flexible case packing configurations.

- Maintains product freshness through MAP and aroma dispensing capabilities.

- Decreases start-up times with its single-block cell design for rapid deployment.

- Meets high output demands with scalable handler options to suit varying production speeds.

- Applications

- Buns, Soft bread, Bakery products

- End products

- Hamburger buns, Sandwich rolls, Sub rolls, Hot dog buns, Slider buns, Dinner rolls, Brioche buns

- Steps before

- Cooling, Product Alignment

- Steps after

- Box Packing, Configuration Viewing

- Input ingredients

- soft bread, buns

- Output ingredients

- packaged soft bread, packaged buns, boxed products

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation level

- Fully automated

- Product alignment system

- Chicane system

- Product distribution

- Double multiplier

- Feeder conveyor

- Artic horizontal wrapper

- Packaging capability

- MAP, aroma dispensing

- Case packing cell type

- Single-block, servo-driven handler

- Box pattern configuration

- Intuitive operation, HMI

- Handler type

- Single/double for speed

- Working mechanism

- Automated packaging and case packing

- Integrated steps

- Primary packaging with horizontal wrapping

- Automation level

- Flexible and configurable

- Changeover time

- Quick pattern change via HMI

- Batch vs. continuous operation

- Continuous operation

- Case packing system

- Servo-driven handler with configurable patterns

- Food-grade compatibility

- Yes

- Corrosion resistance

- Stainless Steel

- Abrasion resistance

- Moderate

- Cleanability

- High

- Biological compatibility

- Yes

- Feed method

- Spiral cooler feed

- Product alignment

- Chicane system

- Discharge method

- Grouping module and feeder conveyor

- Packing configuration

- Single or double handler

- Control panel type

- HMI with intuitive operation

- Control panel type

- Intuitive HMI

- Integration possibilities

- Single or double handler configuration

- Pattern programming

- Flexible and configurable box patterns

- Operation view

- Configuration viewable on HMI

- Start-up time customization

- Single-block cell reduces start-up times