Industrial lye coating line for bakery products

Streamline your bakery operations with high-speed lye coating technology that ensures consistent and high-quality pretzel and croissant finishes.

Applies Lye Coating to Bakery Products

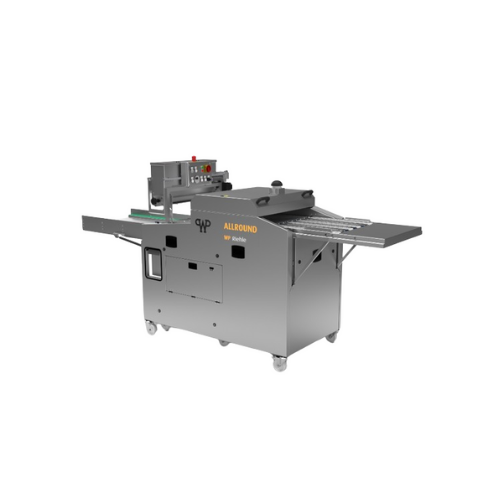

The Belaugungsanlage ALLROUND from WP Riehle is an automated lye coating machine designed for the efficient production of a range of bakery products, including pretzels, croissants, and pastries. It features a patent-pending lye shower and dual lye curtain to ensure optimal and consistent coating results, even at high processing speeds. This machine supports continuous operations and can process up to 400 trays per hour, making it ideal for large-scale production environments.

Utilizing an adjustable conveyor speed, the ALLROUND integrates seamlessly into existing bakery production lines, offering modular extension options such as an optional salt applicator and depositor band for clean processing. Its expansive 180-liter lye tank is equipped with a heating system to maintain temperature, improving coating quality while preventing cooling. The machine’s space-efficient design includes foldable input and output tables, enhancing operational flexibility in constrained spaces.

This system suits bakeries aiming to enhance throughput and coating uniformity, featuring decentralized control with sensor alerts for low lye levels and configurable options for different baking workflows. Engineered to withstand frequent use, it provides robust performance with minimal maintenance requirements, embodying WP Riehle’s commitment to quality and efficiency in food processing technology.

Benefits

- Increases production capacity with high-speed throughput of up to 400 trays per hour.

- Ensures consistent lye application with a patented dual lye curtain, enhancing product quality.

- Simplifies integration into existing lines with adjustable conveyor speeds and optional modules.

- Preserves energy efficiency by maintaining lye temperature with an advanced heating system.

- Minimizes operational footprint with space-saving, foldable table design for compact setups.

- Applications

- Breadsticks, Snack foods, Croissants, Pastries, Bakery products, Pretzels

- End products

- Croissant, Laugenbrötchen, Brezel, Laugenstange, Laugenkonfekt

- Steps before

- Dough Preparation, Dough Shaping

- Steps after

- Baking, Cooling, Packing

- Input ingredients

- dough, brine solution

- Output ingredients

- laugegebäcke, brezel, laugenbrötchen, laugenstange, croissant, laugenkonfekt

- Market info

- Capacity

- 1500-4000 pieces/day

- Speed

- Up to 400 trays/hour

- Laugentank Capacity

- 180 Liters

- Automation

- Automatic Laugen level sensor

- Heated Tank

- Temperature-adjustable to prevent temperature drop

- Adjustable Speed

- Yes

- Modular Features

- Optional Salzer and Ablegeband

- Space-saving Design

- Collapsible input and output tables

- Processing Speed

- 1500-4000 pieces per day

- Batch vs. Continuous Operation

- Continuous

- Adjustable Speed

- Yes

- Automation Level

- PLC-controlled

- Heating Control

- Adjustable

- Laugenbehälter Type

- Closed 180-liter tank

- Abrasion resistance

- High

- Biological compatibility

- Food-grade

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Density/particle size

- Variable

- Lye type

- NaOH / KOH

- Suitable products

- Brezel, Laugenbrötchen

- Machine footprint

- Compact, with foldable input and output tables

- Tank capacity

- 180 Liters

- Tank type

- Closed, with adjustable heating

- Feed method

- Conveyor system

- Discharge method

- Conveyor system

- Laugen system

- Patented Lauge shower and dual Lauge curtain

- Construction material

- Stainless steel

- Optional components

- Salzer with exchangeable containers, discharge belt

- Modular Options

- Optional Salzer with changeable containers

- Modular Options

- Optional Discharge Band

- Process Control

- Adjustable Running Speed

- Lye Temperature Control

- Adjustable heating

- Space Saving

- Foldable Input and Output Tables