Vacuum conveyors

Connect directly with world-leading production technology suppliers of innovative vacuum conveyors

Vacuum conveying systems use a pressure gradient to move the product from the inlet to the outlet of a piped system. These systems use a vacuum generator at the delivery end of the pipe to create a vacuum that pulls the material through, unlike pneumatic conveying systems which use air compressors at the inlet to push the material. In addition to the vacuum generator, a basic vacuum conveying system consists of a pick-up nozzle, the conveying line, bends, diverter valves, and the receiver. Considerations for choosing a vacuum conveyor include the particle size of the product, length and complexity of the flow path, the desired flow rate, sensitivity of the product and dilute or dense phase operation. Vacuum systems are suitable for transporting powdered and granular materials for processing and filling operations in various industries.

What are you making?

Which vacuum conveyors technology do you need?

Vacuum conveyors for explosive and inert gas environments

Optimize the safe transfer of hybrid mixtures and fine powders...

Pharmaceutical vacuum conveyors for hygienic transport

Ensure contamination-free transport of sensitive pharmaceuticals a...

Continuous vacuum conveyors for material flow control

Ensure consistent material transfer and reduce downtime in your pro...

Dust-control sack tip station for industrial loading

Ensure seamless and safe unloading of powders with an integrated dus...

Green coffee conveyor for efficient coffee roasting operations

Effortlessly streamline your roasting process by automati...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Powder handling vacuum conveyor system

Streamline your material transfer with a versatile vacuum conveyor system that ensur...

Metal powder recovery system after 3d printing

Effectively reclaim and purify metal powders after 3D printing to enhance c...

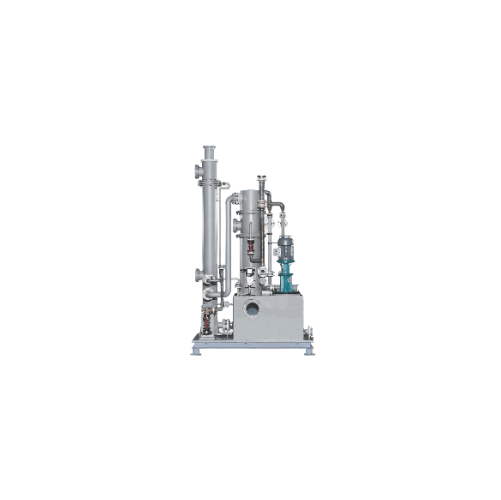

Vacuum deaeration with aroma recovery for juices

Eliminate oxygen from liquid foods to prevent oxidation while retaining v...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Dry scroll vacuum pumps for laboratories and manufacturing

Ensure a clean, oil-free environment with advanced dry scroll...

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

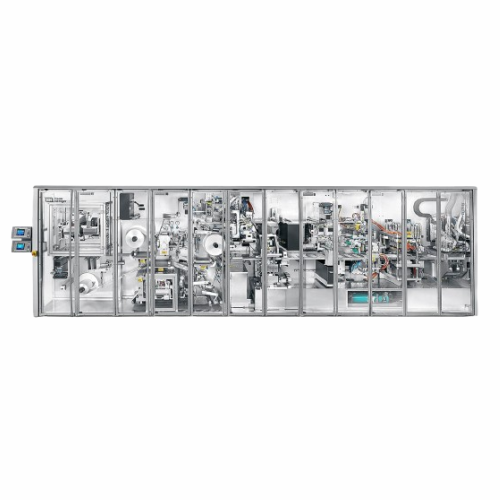

Automated capsule packaging system

Streamline your high-speed packaging operations with a system designed for precision fil...

Vacuum packaging system for food products

Optimize your packaging process with high-speed vacuum technology designed to pr...

Vacuum pressure macro dosing system for dry syrups

Ensure precise dosage and minimal powder spillage with a high-speed va...

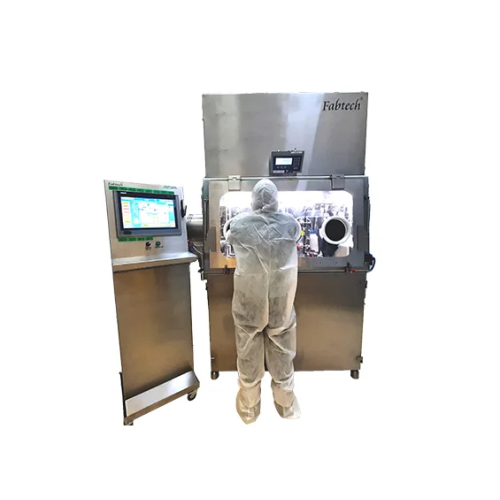

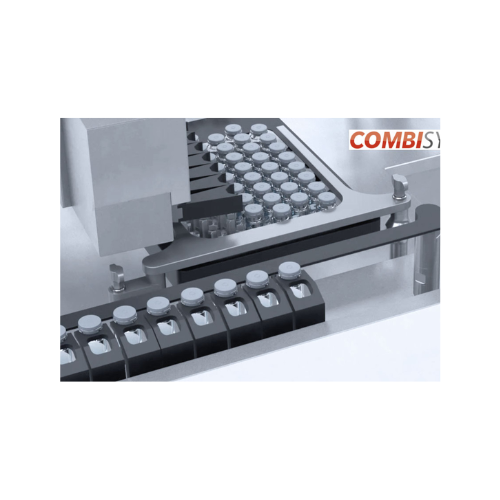

Micro-dosing system for pharmaceutical powders in vials

Ensure accurate aseptic dosing of sensitive pharmaceutical powder...

Vacuum filtration for sterile media and buffer preparation

Achieve reliable sterilization and filtration of cell culture...

Membrane filtration system for bioburden and water testing

Ensure accurate microbial detection and efficient filtration ...

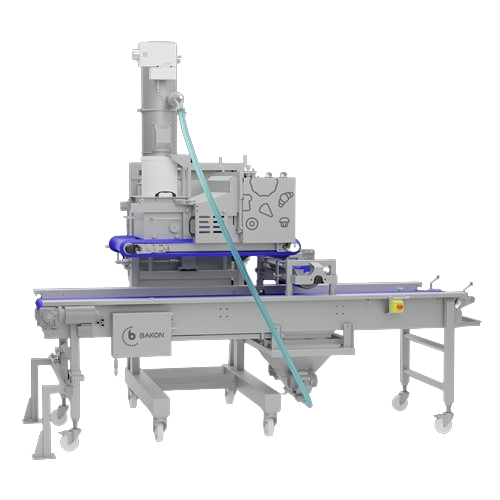

Flour applicator for convenience foods and snacks

Achieve uniformly coated products, such as chicken nuggets and fish fil...

Powder handling systems for battery production

Optimize your battery production with a versatile powder handling system th...

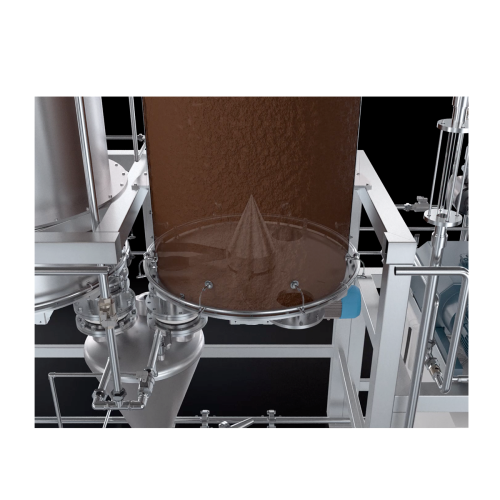

Powder dissolver for large liquid quantities

Achieve uniform powder blending swiftly with a vacuum-assisted system that pr...

Juice product deaerator

Ensure high-quality filling without foam formation through efficient deaeration, perfect for manufact...

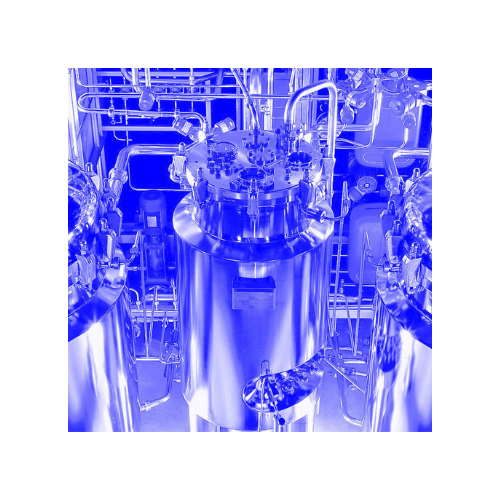

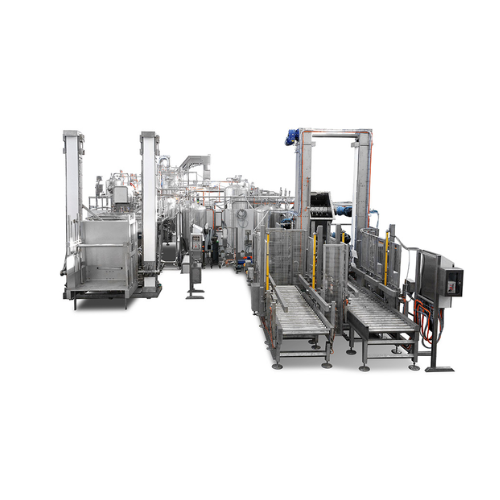

Sterile tank system for aseptic processing

Optimize your production with aseptic tank systems that ensure sterile storage ...

Dense phase vacuum conveying for fragile powders

Efficiently convey fragile powders without compromising their integrity, ...

25kg powder packaging system for sanitary applications

Achieve high accuracy and hygiene in powder packaging with a syste...

Sanitary bulk bag filling system

Streamline your powder handling process with a system designed to improve stability and acc...

Selective ion exchange for copper refining operations

Optimize your copper refining process by efficiently removing conta...

Curd unloader for dairy production

Streamline your cheese production with efficient curd unloading and transfer, ensuring s...

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

Demineralization and carbonation for bottled table water

Ensure consistent carbonation and precise blending for beverage ...

Powder filling and stoppering for antibiotic production

Tackle antibiotic resistance with precision powder filling and st...

Linear vial washer for injectable drug containers

Achieve sterile conditions by efficiently removing contaminants from va...

Ground coffee handling and conveying system

Enhance your coffee production with precise handling systems that ensure aroma...

Material container emptying device

Efficiently unload and empty material containers with adaptable mounting options, ensuri...

Potato slice washer for surface starch and fines removal

Ensure optimal cleaning and dewatering of potato slices while si...

Industrial water removal system for food preparation

Enhance your production line with advanced surface water and starch ...

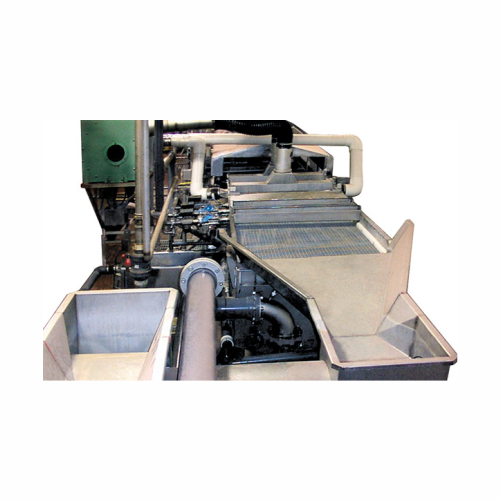

Vacuum belt filters for solid-liquid separation

Ensure high-efficiency solid-liquid separation and maximize filtrate recov...

Vacuum table filters for liquid-solid separation

Optimize your liquid-solid separation with vacuum table filters, designed...

Production of sterilized aluminum blister packs

Optimize your medical product packaging with our high-speed solution for p...

Ultra-hygienic vacuum conveyor for pharmaceutical industry

Optimize powder transfer with ultra-hygienic vacuum conveying...

Ultra-hygienic vacuum conveyor for pharmaceutical and food industries

Streamline material handling with this ultra-hygi...

Dust control sack tip station for bag unloading

Ensure efficient powder unloading and minimize dust emissions in your prod...

Hygienic vacuum conveyor for pharmaceutical and food industries

Optimize your material handling process with a vacuum co...

Empty capsule transfer system

Ensure seamless capsule filling operations by eliminating manual handling and preventing produ...

Filled capsule conveyor system for pharmaceutical production

Ensure gentle and efficient conveying of filled capsules in...

Industrial sausage and ham vacuum filler

Achieve unmatched precision in filling and portioning with high-capacity vacuum te...

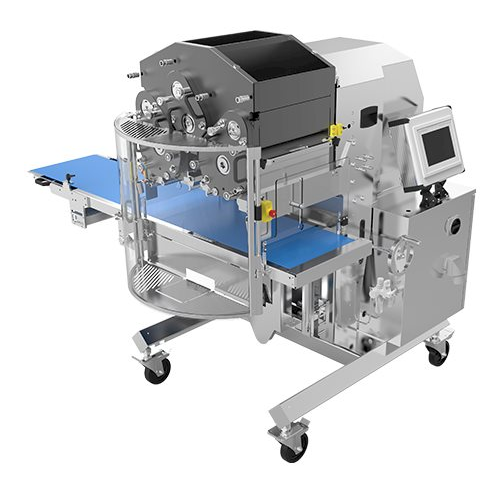

Forming system for minced meat products

Achieve high-quality formed meat and plant-based patties with precision and flexibi...

Large-scale coffee roaster for specialty coffee production

Elevate your coffee production with a high-capacity roaster d...

Vacuum pneumatic conveying for infant nutrition

Ensure efficient handling of delicate powders with a versatile vacuum pneu...

Pneumatic truck unloading for bulk tankers

Efficiently unload bulk materials from trucks with minimal dust emissions while...

Sack tipping station for dust-free bulk material handling

Efficiently manage bulk materials while minimizing dust exposu...

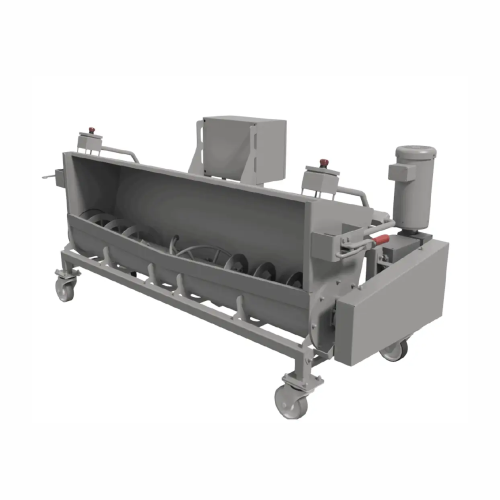

Single shaft batch mixer for chemical and pharmaceutical applications

Optimize mixing efficiency with rapid batch proce...

Laboratory mixer for r&d and small batch production

Achieve superior mixing precision for R&D and pilot production w...

Hygienic flexible sleeves for food and pharmaceutical use

Say goodbye to contamination risks with this tool-free, quick-...

Big bag unloader for industrial bulk materials

Efficiently handle bulk materials with this modular unloading system, desig...

Heavy duty blowing seals for abrasive products

For operations dealing with abrasive materials under high pressure, these r...

Liquid dispensing isolator for sterile environments

Maintain product sterility by utilizing a liquid dispensing isolator ...

Bulk packaging solution for biochar

Protect biochar from rapid oxidation and ignition with a vacuum-sealed, nitrogen-purged...

Fluid bed processor for large batch spray granulation

Optimize your production with precision granulation, drying, and co...

Modular big bag unloading station for various materials

For hassle-free handling of bulk materials, this modular solution...

Drum and container emptying system

Ensure safety and efficiency when handling and emptying drums or containers, whether dea...

Ibc and drum filling system for chemical substances

Ensure safe and efficient handling of sensitive materials with a modu...

Concentrate drum emptying system

Efficiently extract every drop of fruit concentrate from your drums with precision and ease...

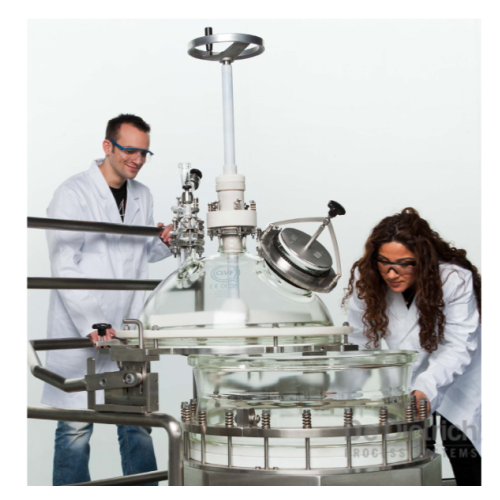

Glass nutsche filter for fine chemical and pharmaceutical filtration

For precise separation and filtration in R&D ...

Big bag emptying station for powder handling

Ensure safe and efficient powder discharge with precision containment, adapta...

Mobile powder transfer system for pharmaceuticals and chemicals

Efficiently transfer and charge powders into various ves...

12l solid/liquid extractor for pilot plant solutions

Optimize your extraction processes with a versatile extractor that a...

High-capacity inline mixer for dairy and beverages production

Achieve a rapid and homogeneous mix in high-capacity produ...

Modified atmosphere packaging for bulk bins

Achieve ultra-low oxygen levels and preserve product quality during bulk proce...

Inclined screw loader for food processing

Optimize your food processing line with an inclined screw loader, designed for e...

Sanitary bulk solids receiver for food and pharma

Ensure precise control over bulk solid transfer with a system designed ...

Laboratory fluid bed dryer for pharmaceutical granulation

Optimize your lab-scale drying and granulation processes with ...

Batch weigh vacuum receiver

Optimize precision in ingredient batching and streamline your production line with advanced vacu...

Feed bins for pre-conditioning materials

Optimize your material flow by pre-conditioning bulk solids for efficient vacuum c...

Industrial vacuum blower for continuous pressure conveying

Optimize your production line with reliable vacuum conveying,...

Vacuum sequencing blower for industrial conveying systems

For manufacturers handling bulk materials like powders and gra...

Casing and flavor preparation kitchens for tobacco industry

Enhance your tobacco product versatility with precision-engi...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Dust particulate extraction system

Ensure safe containment and minimize airborne particulates in your production line with ...

Robotic handling systems for beverage containers and bins

Streamline your container handling with precision-engineered r...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Automatic sleeving for rolled and molded cones

Optimize your cone production line with precision sleeving and reliable det...

Premixer for cream production

Achieve precise mixing of liquid and solid fats for diverse cream formulations with insulated ...

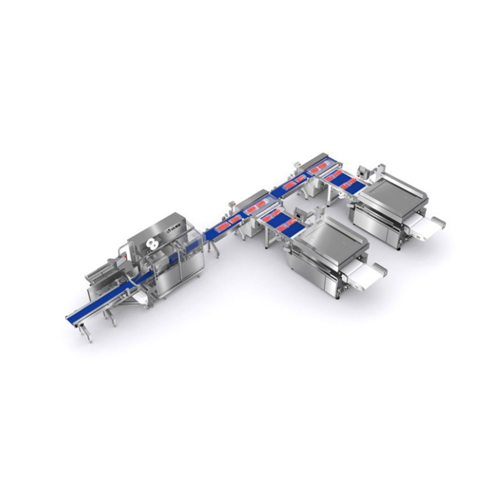

Material handling system for confectionery production

Optimize your production line with a system designed for efficient ...

Ballistic separator for paper, cardboard, and foil

Optimize your waste stream with high-precision material separation, en...

Media and buffer preparation solution for bioprocessing

Achieve seamless media and buffer preparation with precise dosing...

Multi feeding system for baby food and purees

Streamline your puree production with a versatile feeding system that expert...

Automated container loading system for ampoules and syringes

Ensure precise loading and nesting of sterile containers in...

Silicone spraying unit for laboratory and small-scale production

Ensure precise silicone application for cartridges, syr...

Automatic tub de-bagging and de-nesting solution

Efficiently prepare your RTU containers by seamlessly integrating de-bagg...

Efficient topping strewer for bakery production lines

Enhance your product’s appeal and streamline topping applicat...

Integrated pickup station for bagged products and big bags

Streamline the handling and transition of bulk materials with...

Modular big bag discharge station for bulk material handling

Streamline your bulk material handling with a customizable ...

Dust-free big bag connection system for bulk solids

Eliminate dust and ensure reliable discharge with this vacuum docking...

Fine chemical powder system

Optimize your powder processing with a solution tailored to handle complex feeding, conveying, a...

Vacuum conveyor for powder and granule transfer

Ensure efficient and contamination-free transfer of powders and granules w...

Vacuum transfer system with integrated cleaning

Ensure sterile powder handling and contamination-free production with vacu...

Powder hopper loaders for free-flowing materials

Efficiently transport free-flowing powders, including PVC and polyethylen...

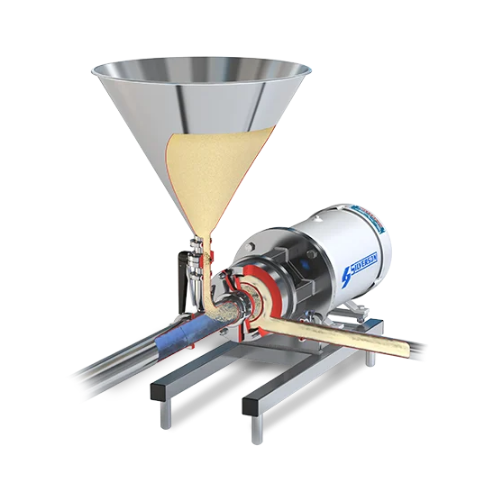

Atmospheric powder induction system

Enhance your mixing efficiency with a system designed for rapid powder induction and th...

Containment tablet coater for high-potency pharmaceuticals

Ensure operator safety and maintain stringent OEB 4 complianc...

Integrated granulation train for pharmaceutical processes

Achieve precise granulation, uniform mixing, and efficient dry...

Automated powder and pellet product conveying system

Optimize your encapsulation process effortlessly with this fully aut...

Powder filling machine for dry products

Achieve precision and consistency in filling dry powders and granules with a versat...

Flexible depositor and extruder for small-scale production

Achieve precise multi-mass creations with a compact, versatil...

Automatic inline tray sealer for food packaging

Streamline your packaging process with high-speed, reliable tray sealing t...

In-line vacuum powder filler

Optimize your production line with precise, contamination-free filling for nutritional powders,...

Vacuum powder filler for dairy and pharmaceutical products

Achieve precision and maintain product integrity with a versa...

Big bag loading station for bulk product handling

Efficiently manage big bag handling with a system that combines hoistin...

Lean phase vacuum conveying system for powder handling

Efficiently transport and separate powders and granules with preci...

Vacuum powder sampler for particle size distribution control

Ensure precise quality control with a vacuum powder sampler...

Intermittent motion bulk packaging for pasta and granular products

Optimize your production line with precision packagi...

Marine water treatment systems

Effectively manage marine water systems with solutions designed to purify bilge water, extrac...

Inline automatic powder fillers for food and nutraceuticals

Ensure precise and efficient filling of sensitive powders in...

Aerosol separator system for industrial emission control

Enhance your emission control measures with our aerosol separato...

Vacuum hopper loader for automatic feeding of powders and pellets

Optimize your material handling with seamless automat...

High-pressure rotary feeder for continuous powder handling

Optimize your production line with reliable powder handling, ...

Rotary feeder for powdered bulk materials

Achieve precise control in feeding and discharging powdered materials with a rot...

Powder wetting and dispersion system

Revolutionize your production with a system that seamlessly inducts, wets, and dispers...

Inline disperser for food production

Quickly achieve stable, agglomerate-free dispersions and emulsions with minimal manual...

A-type rotary feeder for powder and pelleted bulk materials

Ensure precise feeding and discharging of powdered and pelle...

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

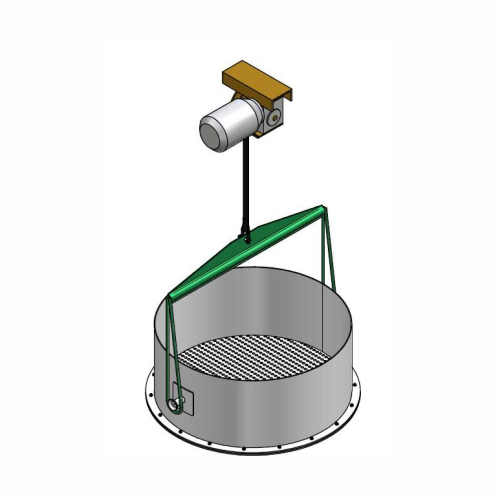

Biomass digester feeding system

Efficiently integrate biomass into your biogas production process with a system that seamles...

Vertical screw conveyors for sludge handling

Efficiently lift and blend sludge with minimal footprint and costs, while ens...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

High flow rate Fibc discharger

Optimize your bulk material handling with a system designed for efficient and dust-free FIBC ...

Automatic bag splitter for bulk solids handling

Streamline your production line with an efficient solution to split, empty...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Explosion-proof electric motovibrators for oil & gas industry

Ensure safe and efficient material flow with explosion-pro...

Loading bellows for drums and Ibcs

Ensure dust-free loading of bulk solids into confined spaces with compact, pneumatically...

Open truck loading bellows with dust collector

Achieve efficient, dust-free loading of dry bulk solids into open trucks, m...

Vacuum conveyor for tablets and capsules

Ensure the integrity of your tablets and capsules with gentle vacuum conveying des...

Integrated conveying and weighing system for bulk materials

Achieve precise material management with a solution that sea...

Vibratory feeder for dosing powders and bulks

Ensure precise feeding of powders and bulk materials with a system that inte...

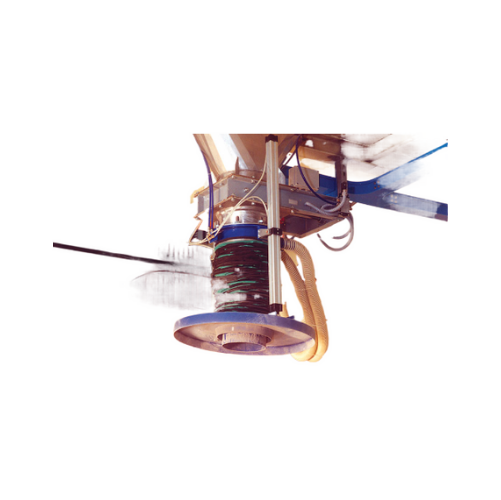

Closed powder handling loop for Eos metal Am printers

Effortlessly manage metal 3D printing powders with a solution that ...

Metal powder buffer storage for additive manufacturing

Streamline your additive manufacturing workflow with our advanced ...

Industrial vacuum pumps for efficient powder conveyance

Harness the power of efficient vacuum generation to streamline th...

Bag rip-and-tip dump stations for bag emptying

Efficiently manage bag emptying operations with advanced dust containment a...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Containment system for product loading

Ensure safe handling of hazardous materials with this containment system, designed t...

Drum discharge system for bulk material handling

Achieve precise, gentle transfer of sensitive pharmaceuticals and granula...

Ibc docking and discharge stations

Ensure seamless material transfer with dust-free docking and effective discharge, mainta...

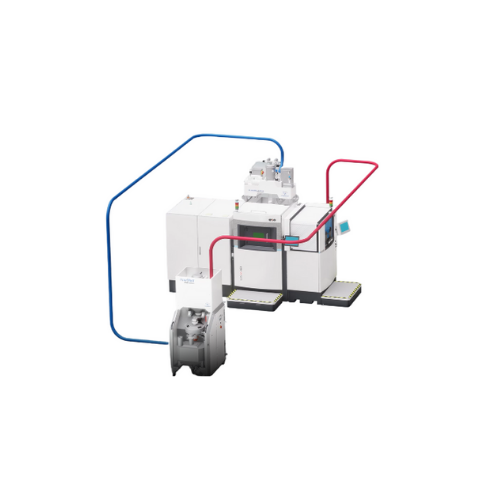

Automatic metal powder filling system for 3d printers

Ensure seamless operation of your 3D printing process with a system...

Automatic unpacking and depowdering station for metal 3d prints

Streamline your post-printing process with a solution th...

Docking station for intermediate bulk container (ibc)

Streamline your metal powder management by efficiently connecting a...

Vacuum dissolver for high viscosity products

Optimize your production with a vacuum dissolver designed to efficiently prev...

Lump breaker for breaking agglomerates and lumps

Effortlessly break down challenging agglomerates and clumps to ensure smo...

Explosion-proof vacuum disperser for high-viscosity substances

Achieve precise dispersion and eliminate air inclusions w...

Industrial fluid and paste preparation system

Eliminate air bubbles and achieve uniform viscosity in fluids and pastes to ...

Consistent material supply system for industrial applications

Ensure seamless production with a system designed for cont...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Continuous motion liquid packaging system

Achieve precise and clean liquid packaging with advanced servo-driven squeegee s...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Brushing systems for agricultural produce

Enhance the precision and efficiency of fruit and vegetable processing with vers...

Pepper sorting and grading technology

Ensure consistent quality and precision in size and color sorting for a wide array of...

Vacuum packaging for industrial cuts of meat

Enhance production efficiency and packaging integrity with a system designed ...

Pharmaceutical drops and sprays filling system

Streamline your liquid formulation process with precision filling and seali...

Food production conveyors for efficient material handling

Streamline your food production with versatile conveyors desig...

Fresh cheese former for hygienic production

Streamline your cheese production with a hygienic and no-mould solution that s...

Vibrating conveyor for short-distance powder transport

Achieve precise and hygienic powder conveying and dosing with this...

Pneumatic conveyor for fragile powders

Handle your delicate powders with care, ensuring minimal breakdown while achieving h...

Vacuum bottling equipment for wineries and breweries

Optimize your bottling process with a vacuum solution that fills up ...

Vacuum filler for wine and oils

Optimize your beverage bottling process with a compact vacuum filler designed for precise le...

Caramel treats production line

Enhance your snack production with a comprehensive solution for crafting caramel treats, effi...

Accu-feed system for dry material separation

Boost efficiency by combining storage, feeding, and screening into one space-...

Vacuum belt filter for sludge and suspension filtration

Optimize your production line with efficient filtration and dewat...

Degassing and mixing unit for beverage production

Ensure precise beverage formulation and maintain high quality standards...

Powder/liquid mixing system for homogeneous dispersions

Struggling to integrate challenging powders into liquid formulati...

High shear powder mixing solution

Achieve agglomerate-free, homogeneous mixing of powders and liquids with high shear effic...

Pneumatic conveying system for dry bulk powders

Ensure seamless and contamination-free transfer of pharmaceutical powders ...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

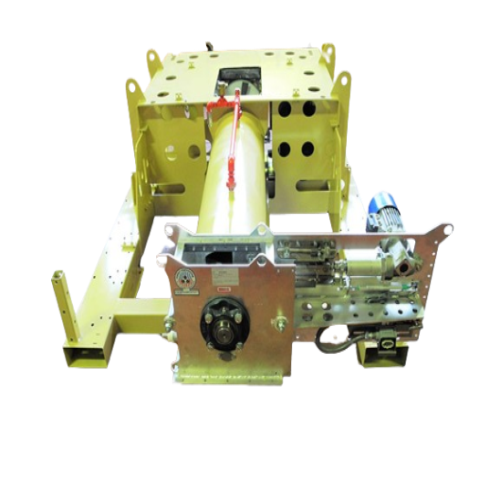

Carcass drum tire building solution

Enhance your tire production with a flexible solution that seamlessly transitions betwe...

Cleaning system for green coffee beans

Ensure optimal purity in your coffee production with a system designed to remove imp...

Degassing system for ground coffee

Optimize your coffee production with a robust degassing solution designed to preserve fl...

Industrial coffee grinder for ground coffee production

Enhance your coffee production line with precise grinding capabili...

Dosing feeder for coffee production

Streamline your coffee production with precision control, ensuring consistent packing l...

Industrial vacuum conveying system

Simplify bulk material movement and separation with a versatile vacuum conveying system,...

Dense phase pneumatic conveying accessories

Optimize material flow and reduce power consumption with dense phase pneumatic...

Semi-automatic filling solution for syringes and vials in isolators

Achieve precise aseptic fill-finish operations for ...

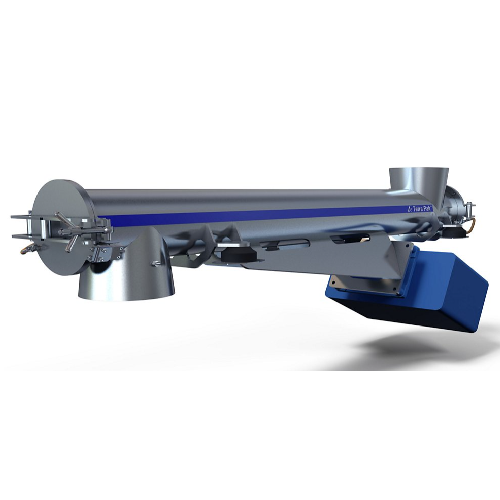

Industrial vacuum conveyor

Oftentime utilized as an alternative to mechanical conveyors when a requirement for dust free con...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

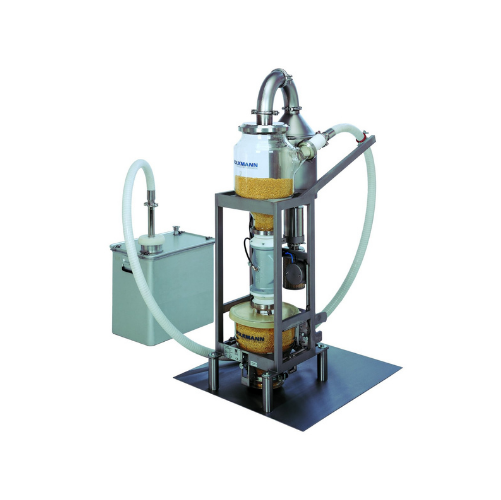

Dense phase conveyor for powders and granules

Some manufacturing and filling operations require a smaller pneumatic transp...

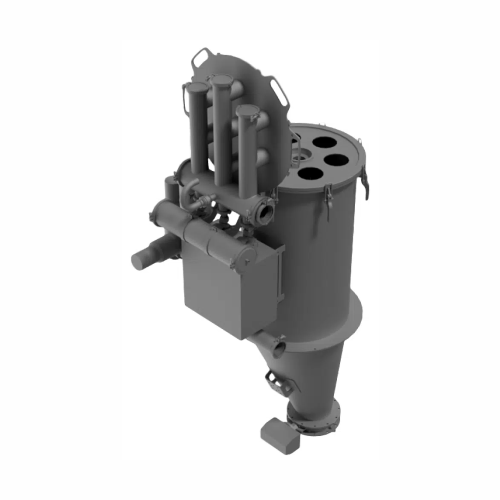

Food vacuum conveyor

Widely used in industries where a high rating in food quality is imperative.