Production of sterilized aluminum blister packs

Optimize your medical product packaging with our high-speed solution for precise and sterile aluminum blister formation, ensuring safe containment and easy integration into your production line.

Packages Medical Products into Sterile Blister Packs

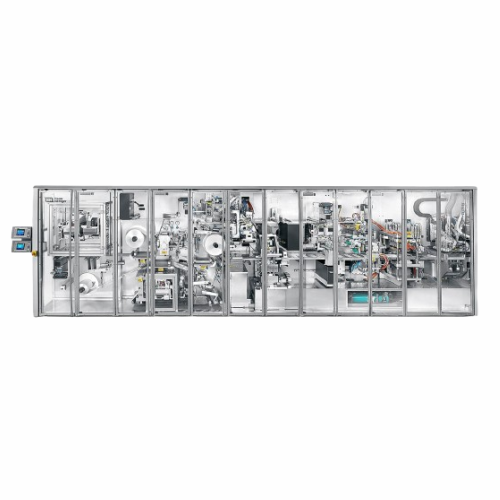

The PFM-KV and PFM-KV 300 from Harro Höfliger are designed to address the unique challenges of packaging medical and pharmaceutical products into sterile blister packs. Utilizing a combination of forming, cutting, sealing, and web handling processes, these machines ensure the integrity and sterility of each package. Capable of producing blister packs for surgical sutures, catheters, and other medical devices, they offer continuous, high-speed, fully automatic operations, making them ideal for use in the medical, pharmaceutical, and biotech industries.

Engineered for seamless line integration, the PFM-KV series allows for precise foil guidance and fast format changes, and supports a wide array of camera systems for quality control. With fully automatic feeding systems, these machines maintain high throughput while ensuring product safety and compliance with industry standards. Available material options and configurations enable customization for specific needs, while robust construction ensures longevity and reliability.

Benefits

- Maximizes production efficiency with continuous, high-speed operation.

- Ensures product sterility with integrated sealing and sterilization-grade packaging.

- Enables rapid adaptability to different product formats with quick changeover capabilities.

- Reduces inspection time with integrated quality control camera systems.

- Minimizes labor involvement with fully automatic feeding and handling systems.

- Applications

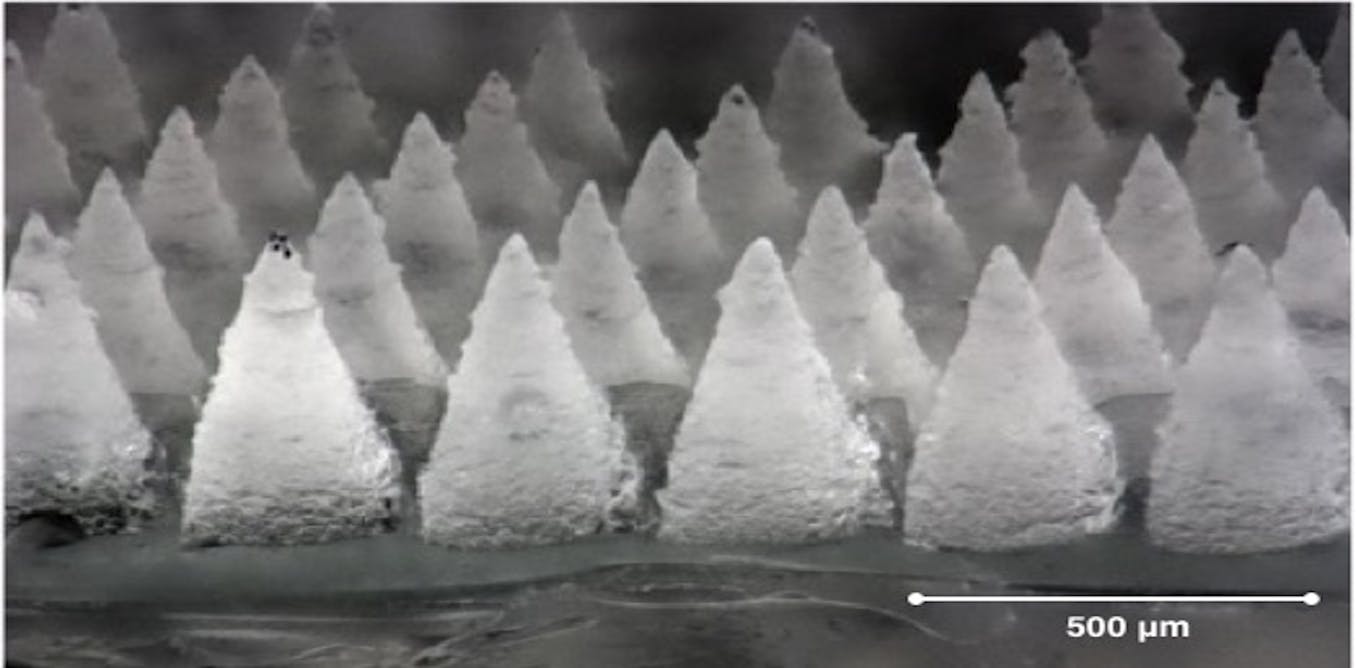

- Catheters, Inhalation products, Transdermal, Eye care products, Microneedles, Surgical sutures, Medical products, Ostomy, Oral delivery systems, Continence care products, Skin care products, Diagnostic products, Pharmaceutical device assembly, Wound

- End products

- Asthma inhaler components, Ostomy pouch systems, Oral thin films, Pre-filled syringe kits, Surgical suture packets, Microneedle patches, Continence care inserts, Transdermal patches, Sterile gauze blister packs, Hydrogel wound dressings, Contact lens blisters, Catheter blister packs

- Steps before

- Material preparation, Foil unwinding, Product sorting

- Steps after

- Sterilization, Packing, Cutting/Punching

- Input ingredients

- aluminum foil, Tyvek® cover film, medical products

- Output ingredients

- sterilized aluminum blisters, surgical suture material, catheters

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Output Speed

- Extremely high

- Foil Guidance Accuracy

- Precise

- Format Change

- Fast

- Print Systems Integration

- Variety of systems

- Camera Systems Integration

- Large variety

- Feeding Systems

- Fully automatic

- Sealing Methods

- Platen, roller, pulse, ultrasonic, thermal

- Automation level

- Fully Automatic

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Fast

- Cleaning method

- Manual / CIP

- Energy efficiency

- High Output Model

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Packaging type

- Sterilized aluminum blister packaging

- Chain conveyor system

- For aluminum foil transport

- Tyvek® cover film option

- Sterilization-grade

- Conveyor foil transport

- Precise foil guidance

- Integrated camera systems

- Variety available

- Feeding systems

- Fully automatic

- Forming methods

- Thermoforming, deep drawing, vacuum forming

- Sealing methods

- Platen, roller, pulse, ultrasonic, thermal

- Cutting systems

- Cutting cylinders, sleeves, flying blades, steel band cutter, laser contour cutter

- Format change

- Fast format change

- Camera system integration

- Large variety of camera systems

- Feeding system

- Fully automatic feeding systems

- Sealing methods

- Platen, roller, pulse, ultrasonic, thermal

- Forming methods

- Thermoforming, deep drawing, vacuum forming