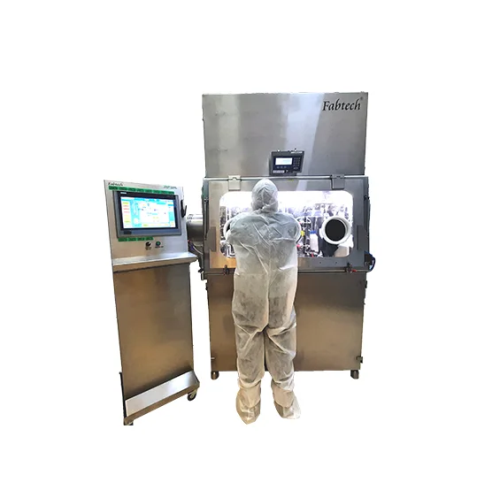

Liquid dispensing isolator for sterile environments

Maintain product sterility by utilizing a liquid dispensing isolator that ensures aseptic conditions for critical manufacturing processes like filtration and transfer, essential for high-purity injectable drugs and healthcare products.

Dispenses and Sterilizes Liquids in Aseptic Conditions

The Liquid Dispensing Isolator from Fabtech is designed for the pharmaceutical, biotech, and healthcare industries to ensure the sterile dispensing of liquids, such as injectable drugs and IV fluids. Constructed from robust SS 316L with ISO 5 Grade A laminar airflow, it facilitates aseptic transfer, measurement, and dispensing of pre-sterile liquids. The system is equipped with inline sterile filters and is compatible with VHP decontamination, ensuring a contamination-free environment. It includes a standard configuration of a Pass Box with 2 glove ports, a main chamber with 4 glove ports, and a glove integrity tester, with options for multiple chamber configurations. On-demand process equipment integration and an optional H2O2 decontamination process further enhance its flexibility. Designed to fit seamlessly into existing production lines, it supports both manual and continuous operations, making it an ideal solution for sterile liquid excipient and vaccine diluent processing.

Benefits

- Ensures contamination-free liquid dispensing with robust aseptic processing capabilities.

- Enhances operational flexibility with customizable chamber configurations for varied production needs.

- Minimizes operational risks with password-protected authorization levels for process integrity.

- Reduces maintenance downtime through integrated glove integrity tester and easy integration with existing systems.

- Achieves superior environmental control with optional H2O2 decontamination and VHP compatibility.

- Applications

- Biopharmaceuticals, Healthcare products, Liquid formulations, Pharmaceuticals

- End products

- Sterile injectable drugs, Iv fluids, Ophthalmic solutions, Antibody drug conjugates, Sterile liquid excipients, Vaccine diluents, Electrolyte solutions

- Steps before

- Purification, Decontamination

- Steps after

- Sterilization, Packing

- Input ingredients

- pre-sterile liquids, products requiring sterile transfer

- Output ingredients

- measured liquids, dispensed sterile liquids, smaller containers with sterile content

- Market info

- Construction Material

- SS 316L

- Airflow Classification

- ISO 5 Grade A

- Chamber Configuration

- Multiple options

- Glove Ports

- 6 total (4 main, 2 pass box)

- Decontamination Compatibility

- VHP (H2O2)

- Particle Counter Integration

- Online

- Password Protection

- Authorization levels

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Construction Material

- SS 316L

- Airflow Classification

- ISO 5 Grade A

- Pass Box Configuration

- 1 Pass Box (2 Glove Ports)

- Main Chamber Configuration

- 4 Glove Ports

- Customization Option

- Multiple Chamber Configuration

- Construction Material

- SS 316L

- Glove Port Configuration

- 2 Glove Ports (Pass Box), 4 Glove Ports (Main Chamber)

- Chamber Configuration

- Multiple Options Available

- Integration Capabilities

- On-demand process equipment, online particle counter

- Decontamination Options

- VHP compatibility, Optional H2O2

- Security Features

- Password protection for different authorization levels