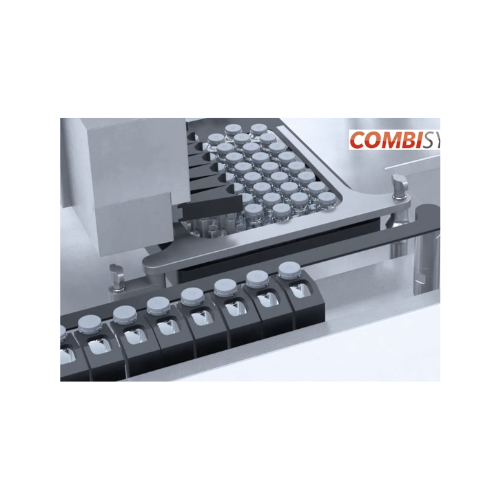

Automated container loading system for ampoules and syringes

Ensure precise loading and nesting of sterile containers in high-speed pharmaceutical packaging, optimizing efficiency and reducing contamination risks in liquid formulations processing.

Loads and Nests Containers with Precision

The MEC 80106 from Bausch+Ströbel is a specialized nest and tub loading machine designed for pharmaceutical and biotech applications. It expertly handles the loading, nesting, and packing of containers with efficiency and precision, accommodating a wide processing range of container diameters and heights. With a throughput of up to 12,000 items per hour, this machine is suited for the production of sterile injectable solutions, pre-filled syringes, and biologic drugs. Its modular design ensures straightforward integration into existing production lines, compatible with RABS and isolators for high process reliability. Built for pharmaceutical environments, it features an optimal laminar air flow system and offers easy central operation. Maintenance is streamlined with optional extras such as a service portal vision system and various checking devices. The MEC 80106 complies with stringent GMP standards, making it an ideal choice for companies demanding cleanroom-compatible, high-speed automation.

Benefits

- Enhances production efficiency by seamlessly handling up to 12,000 containers per hour.

- Reduces operational errors with precise container nesting and placement capabilities.

- Minimizes energy consumption through optimized modular design.

- Ensures high process reliability in sterile environments with RABS/isolator compatibility.

- Simplifies line integration and maintenance with easy operation and optional service upgrades.

- Applications

- Liquid formulations, Syringes, Ampoules, Biopharmaceuticals, Pharmaceuticals

- End products

- Biologic drugs, Injectable antibiotics, Liquid vaccines, Pre-filled syringes, Anesthetic ampoules, Monoclonal antibody formulations, Sterile injectable solutions, Hormonal injections

- Steps before

- Filling, Capping

- Steps after

- Sterilization, Packing

- Input ingredients

- filled containers, closed containers

- Output ingredients

- nests, tubs, fully loaded nests

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Output

- up to 12, 000 items/h (Ampoules)

- Container Diameter

- 7 - 47 mm

- Container Height

- 35 - 100 mm

- Syringe Volume

- 0.5 - 10 ml

- Automation

- Automatic placing of nests into tubs

- Operation

- Easy and centralized

- Design

- Compact

- Set-up Time

- Short

- Process Reliability

- High

- Air Flow

- Laminar

- Compatibility

- RABS / Isolator

- Software Upgrades

- Available

- Vision System

- Cleanroom compatible

- Checking and Alarm Devices

- Available

- Automation level

- Automatic

- Changeover time

- Short

- Batch vs. continuous operation

- Batch

- Cleaning method

- Suitable for RABS/isolator

- Modular design

- Yes

- Energy efficiency

- High

- Process reliability

- High

- Set-up time

- Short

- Airflow control

- Optimal laminar air flow

- Container size range

- Diameter

- Container height range

- Height

- Container type

- Ampoules, Syringes

- Machine Footprint

- Compact Design

- Holder Type

- Suction Compact Holders

- Holder Distance

- Variable

- Processing Range

- Container Diameter

- Container Height

- 35 - 100 mm

- Syringe Volume

- 0.5 - 10 ml

- Output

- Up to 12, 000 items/h (Ampoules)

- Control panel type

- Centralized operation

- Discharge method

- Automatic placement into tubs

- Compact footprint

- Compact design