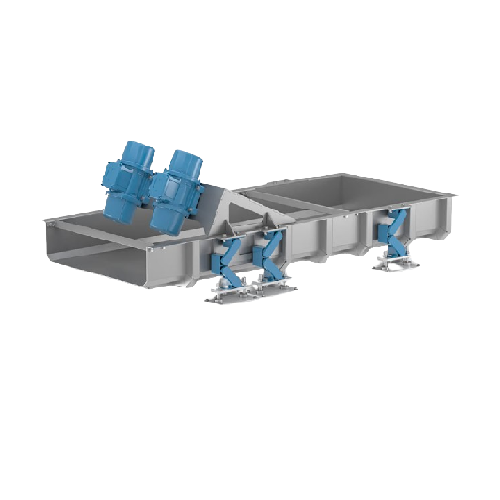

Industrial vibrating table for uniform product transport

Ensure consistent material flow and efficient transport with an industrial vibrating table, optimizing your production line by minimizing manual handling and reducing the risk of product damage.

Uniformly Transports and Vibrates Solid Materials

The PV Vibrating Table by GEA is engineered to enhance material transport in food, beverage, and pharmaceutical processes. This equipment features a robust stainless steel tank and a painted carbon steel frame supported by suspension elements to minimize oscillation. Key to its function are two rotary electric vibrators directly mounted to the tank, allowing manual adjustment of eccentric weights for precise control. The vibrating table efficiently conveys solid and granule products, addressing challenges in continuous operations for alternative protein and dairy processing. With optional product presence sensors, it integrates smoothly into existing lines, maintaining consistent material flow. GEA’s PV Vibrating Table is available with customization options to meet specific industrial requirements and ensure compliance with relevant industry standards.

Benefits

- Ensures uniform material transport, minimizing process bottlenecks in continuous operations.

- Adjustable vibrating mechanism enhances handling of varying product types and weights.

- Stainless steel construction offers durability and corrosion resistance for long-term use.

- Reduces operational interruptions with optional product presence sensors.

- Integrates seamlessly into existing production lines, supporting efficient process flow.

- Applications

- Food, Beverage, Dairy alternatives, Meat alternatives, Seafood alternatives, Egg alternatives, Alternative protein, Pharmaceuticals

- End products

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Tank Material

- Stainless Steel

- Frame Material

- Painted Carbon Steel

- Vibrating Unit

- Two Rotary Electric Vibrators

- Manual Adjustment

- Eccentric Weights

- Suspension Elements

- Variability based on size

- Product Transport

- Uniform Manner

- Optional Feature

- Product Presence Sensor

- Working mechanism

- Vibrating transport

- Automation level

- Manual / Adjustable

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Energy efficiency

- Optimized for low energy consumption

- Corrosive resistance (e.g. acids)

- Stainless steel tank

- Cleanability

- Stainless steel

- Abrasion resistance

- Painted carbon steel frame

- Tank Material

- Stainless Steel

- Frame Material

- Painted Carbon Steel

- Vibrating Unit

- Two Rotary Electric Vibrators

- Suspension Elements

- Variable

- Overall Design

- Easy Access for Manual Adjustment

- Discharge Method

- Uniform Transport to User System

- Vibrator type

- Rotary electric vibrators

- Suspension elements

- Varies by size

- Tank material type

- Stainless steel

- Frame material

- Painted carbon steel

- Eccentric weight adjustment

- Manual

- Product presence sensor

- Optional