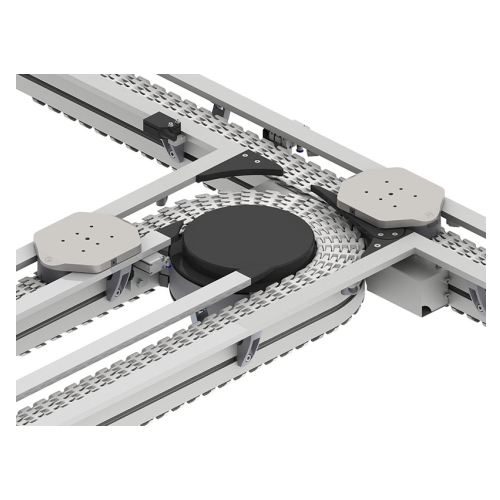

Single track pallet conveyor for productions cells

Streamline your production operations with a versatile pallet conveyor designed to handle diverse product sizes and weights, enhancing traceability and logistical control for single-piece flow applications.

Handles and Tracks Pallets for Efficient Logistics

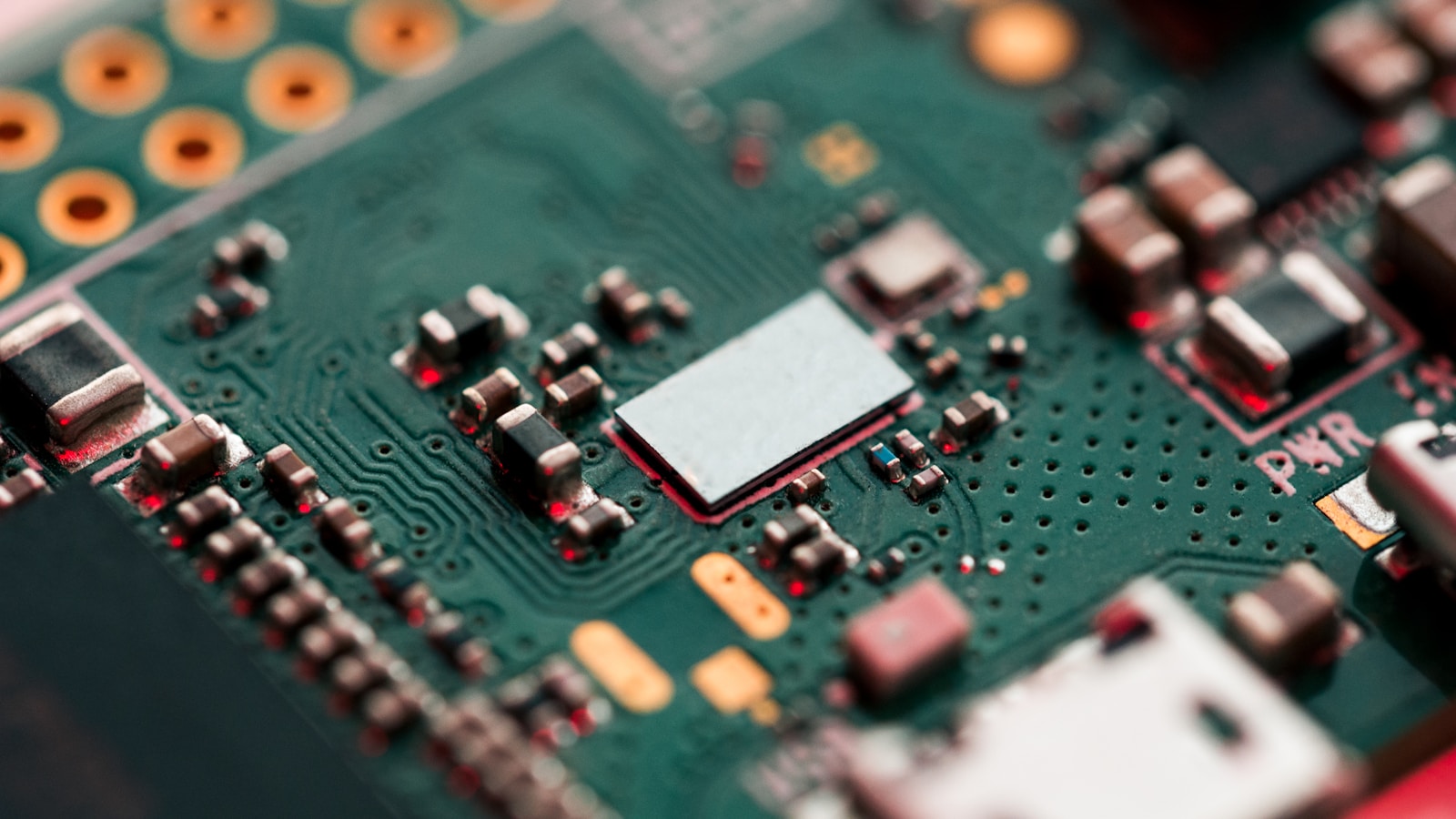

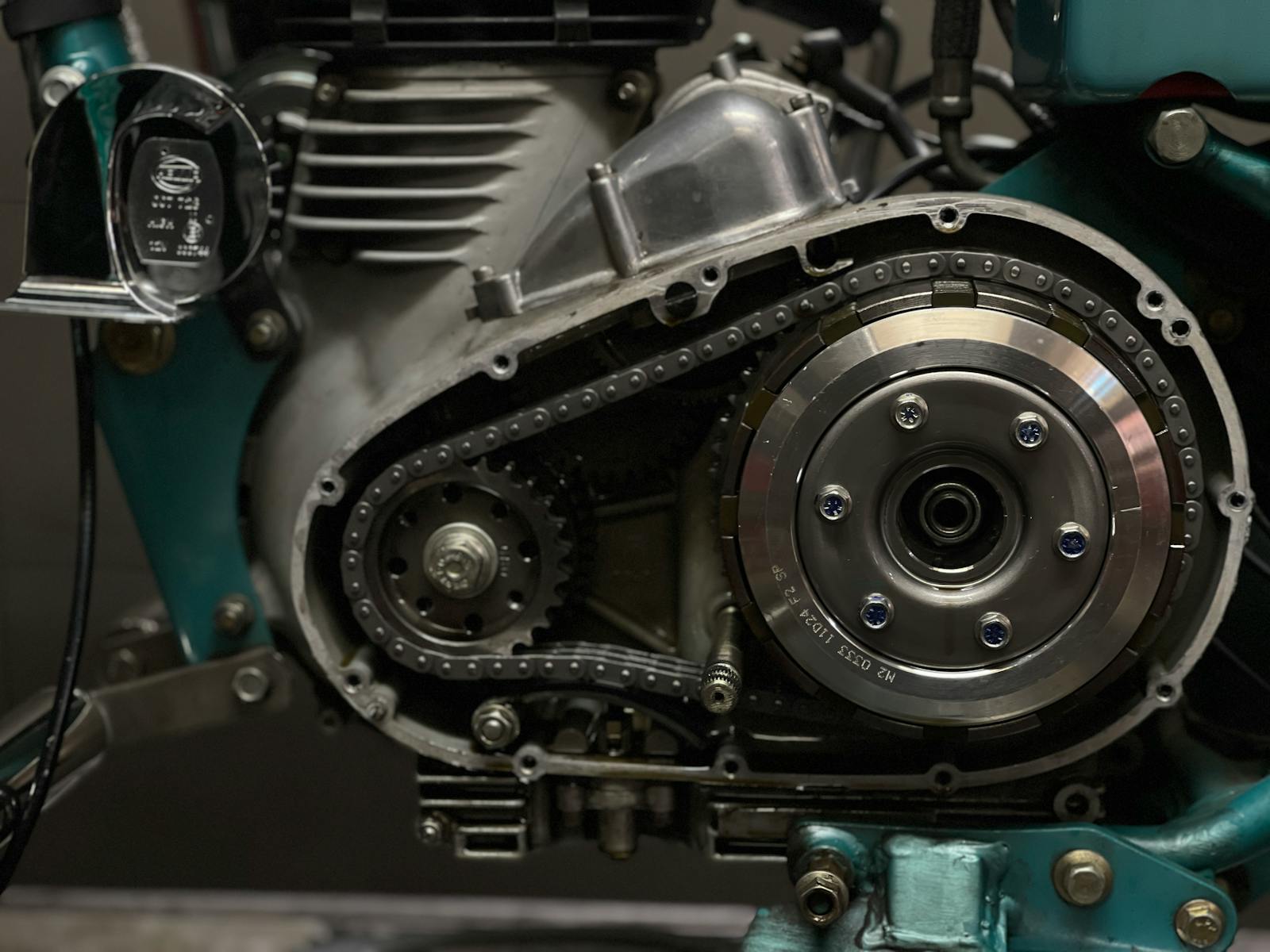

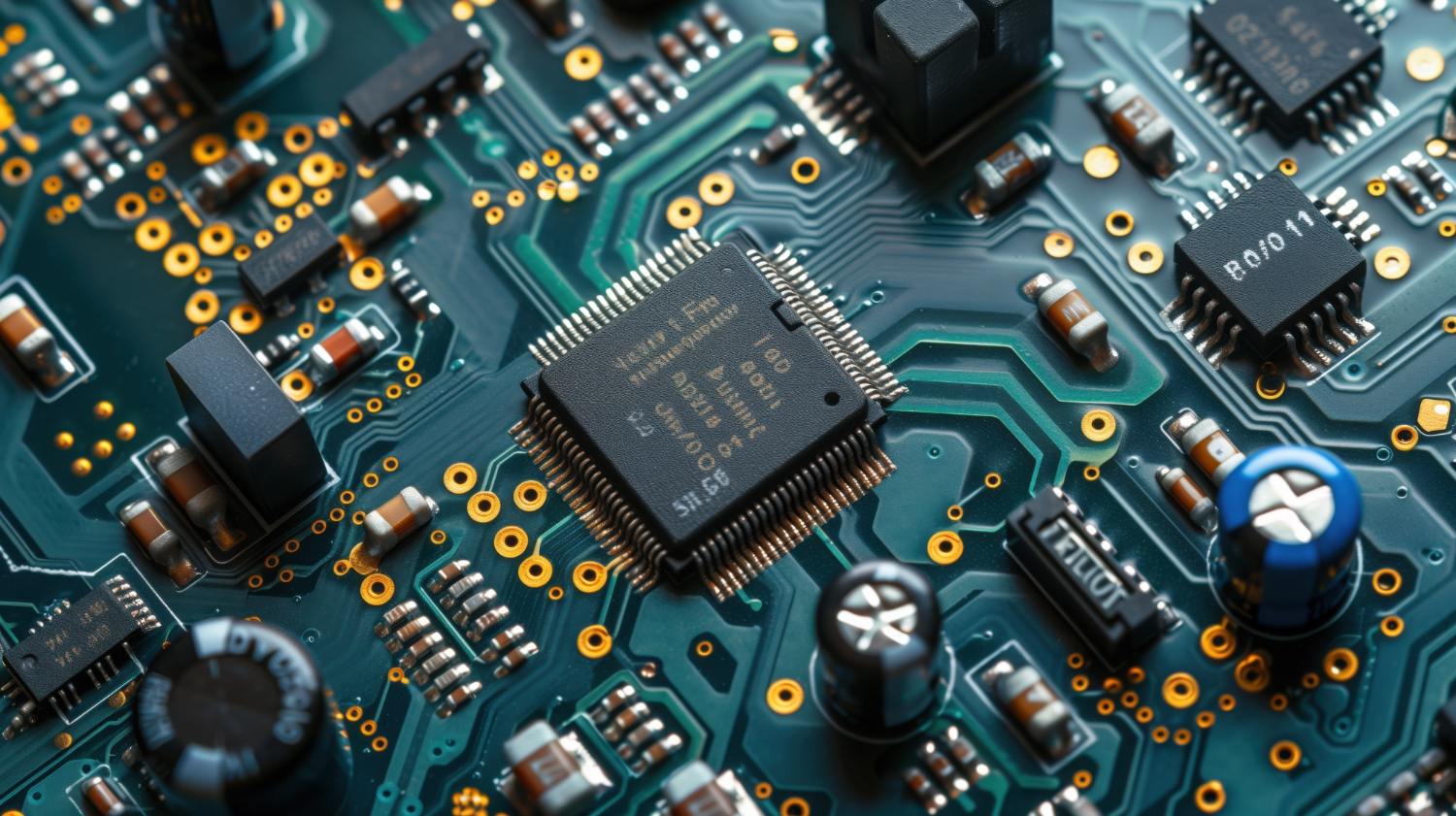

The X85P Single Track Pallet Conveyor from FlexLink is engineered to seamlessly handle and track product carriers within production lines, offering superior routing, balancing, and buffering capabilities. This conveyor utilizes a standardized module design, enabling rapid configuration of complex layouts suitable for electronics to automotive components. With the capability of handling products up to 10 kg and a pallet width of 85 mm, it ensures efficient logistics with RFID-enabled track-and-trace features for high-speed operations. Its integration with other FlexLink solutions, such as spiral and plastic chain conveyors, optimizes flow in dry environments with operating temperatures ranging from -20°C to +60°C. The X85P is ideal for continuous operation in sectors demanding stringent logistic control, ensuring compatibility with a wide range of solid products, from microchips and medical devices to engine parts. Configurable options and FlexLink’s engineering support further enhance its adaptability for production challenges, ensuring streamlined operations across departments.

Benefits

- Enhances efficiency with rapid configuration and integration into existing production lines.

- Ensures precise logistic control through RFID-enabled track-and-trace for real-time monitoring.

- Minimizes handling errors and increases throughput with reliable pallet management.

- Adapts to diverse product sizes and weights, supporting flexible manufacturing needs.

- Streamlines operations in dry environments with a maintenance-friendly design.

- Applications

- Automotive, Pharma, Healthcare, Industrial goods, Electronics, Racing

- End products

- Circuit boards, Engine parts, Syringes, Medical devices, Automotive components, Microchips, Industrial machinery parts, Medical tablets, Racing car parts

- Steps before

- Routing, Balancing, Buffering, Positioning

- Steps after

- Track-and-trace, Logistic control, Palletizing

- Input ingredients

- individual products, product carriers, pallets, products up to 10 kg, clean products, dirty products, dry products

- Output ingredients

- tracked products, positioned pallets, products with track-and-trace, logistically controlled products

- Market info

- FlexLink (Coesia Group) is renowned for its innovative conveyor and automation systems, optimizing production efficiency for various industries such as food, automotive, and electronics, with a strong emphasis on modular and customizable solutions.

- Max Product Weight

- Up to 10 kg

- Pallet Width

- 85 mm

- Max Speed

- 30 m/min

- Operating Temperature

- -20 to +60 °C

- RFID Identification

- Track-and-trace enabled

- Product Length

- Max 225 mm

- Product Width

- Max 160 mm

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- High

- Density/particle size

- Varies

- Pallet width

- 85 mm

- Max product length

- 225 mm

- Max product width

- 160 mm

- Integration possibilities

- RFID track-and-trace

- Layout configurability

- Advanced and straightforward

- Pallet width options

- 85 mm standard