Continuous proofer and oven systems for commercial bakeries

Enhance product consistency and throughput in your bakery operations with cutting-edge systems designed for precise proofing and baking of diverse baked goods, ensuring every product—from soft breads to flaky pastries—meets exacting quality standards.

Processes and Bakes a Variety of Baked Goods

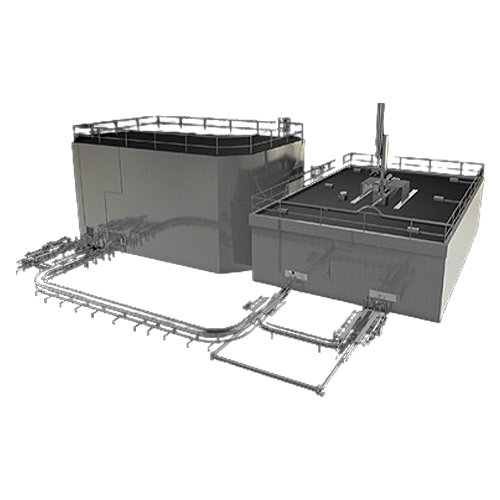

The BakeTech Continuous Proofer and Oven System from AMF BakeTech is engineered to streamline your commercial baking operations. With its unique continuous conveyorized design, this system ensures that each baked product, from gluten-free bread to artisan rolls, receives uniform heat treatment with precise heat placement, thanks to its superior burner configuration. Capable of processing a wide range of goods, including pizza crusts, pastries, and brioche rolls, it integrates seamlessly into high-speed production lines. The system operates continuously, featuring conveyance and inverting mechanisms to easily transition products through proofing, baking, and cooling stages. Energy efficiency is enhanced by the optimized burner placement, which reduces energy consumption while maintaining product quality. It supports a variety of product sizes and types, ensuring versatility in industrial and commercial bakery settings. Additionally, with customization options and engineering support from AMF, this system can be tailored to meet specific production requirements, ensuring performance and efficiency are maximized.

Benefits

- Ensures consistent product quality with uniform heat distribution and exact heat placement.

- Enhances operational efficiency through continuous and conveyorized processing, reducing transition time between stages.

- Offers versatility to accommodate a wide variety of baked goods, from bread to pastries, optimizing production flexibility.

- Minimizes energy usage by leveraging optimized burner configurations, contributing to more sustainable operations.

- Easily integrates into existing production lines with customizable configurations and engineering support, facilitating seamless upgrades.

- Applications

- Buns, Flatbreads, Pizza, Pies, Soft bread, Rolls, Cakes, Pastries, Croissants, Commercial baked products, Artisan bread

- End products

- Baguettes, Swirl breads, Sheeted pizza crusts, Organic rye bread, Puff pastries, Muffins, Brioche rolls, Hoagie rolls, Sweet pies, Savory pies, Pressed pan pizza bases, Gluten-free bread, Cinnamon rolls, Danish pastries

- Steps before

- Dough Mixing, Dough Distribution, Proofing

- Steps after

- Cooling, Freezing, Slicing, Bagging, Packaging

- Input ingredients

- gluten-free dough, organic bread dough, rye bread dough, brioche rolls dough, cinnamon rolls dough, hoagie rolls dough

- Output ingredients

- gluten-free bread, organic bread, rye bread, brioche rolls, cinnamon rolls, hoagie rolls

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Automation

- PLC-controlled

- Capacity

- Customizable based on requirements

- Baking uniformity

- Twice as many burners for exact heat placement

- Flexibility

- Conveyorized proofing, cooling, and baking systems

- System configuration

- Tailored to bakery needs

- Cooling method

- Continuous coolers

- Working Mechanism

- Continuous, Conveyorized

- Integrated Steps

- Proofing, Baking, Cooling

- Automation Level

- SCADA / PLC-controlled

- Heat Placement

- Exact, with Twice as Many Burners

- System Configuration

- Tailored to Bakery's Layout and Application

- Layout Flexibility

- Maximum Layout Flexibility

- Energy Efficiency

- Reduces Energy Usage

- Process Validation

- Scorpion® Oven Profiling and Analysis

- Product Uniformity

- Ensures Consistent, Uniformly Baked Products

- Batch vs. Continuous Operation

- Inline Continuous

- Changeover Time

- 0

- CIP/SIP

- 0

- Cleaning Method

- 0

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Variable, depending on system configuration

- Burner count

- Twice as many as competing ovens

- Conveyorized system

- Continuous

- Pan handling

- Tray in, tray out

- System configuration

- Customizable to bakery layout

- Proofer system

- Continuous

- Oven system

- Continuous

- Cooler system

- Continuous

- Control panel type

- HMI/PLC

- System integration capabilities

- AMFConnect™ compatibility

- Layout flexibility

- High