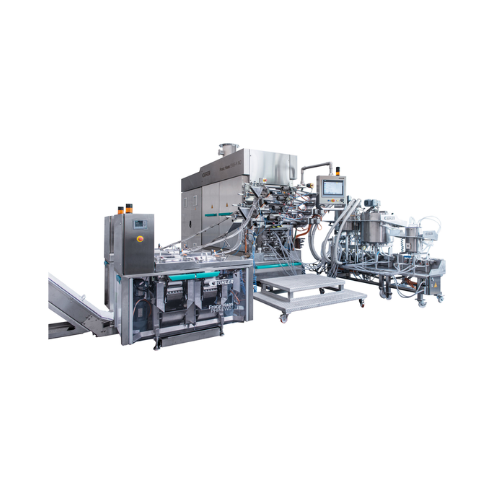

Wafer stick baking oven

Enhance your confectionery production with precision, from forming to filling and coating, achieving exceptional product variety in wafer sticks and snacks with sustainable and energy-efficient induction heating.

Bakes and Forms Diverse Wafer Stick Varieties

The Franz Haas EWB-R IND from Bühler Group is a fully automatic wafer stick baking oven engineered for continuous production lines in the food, confectionery, and snack industries. Utilizing emission-free induction heating, this oven efficiently bakes strips of batter high in sugar content onto a revolving heated baking ring. After baking, precision stripping knives release the batter strips, which are then formed into various wafer stick designs, including filled, two-colored, and fan-shaped options. The system integrates seamlessly with other production stages, offering add-ons for twisting, crimping, and coating, thus enhancing product diversity. It boasts an intuitive touch-screen operation, allowing easy adjustments for custom end-product designs. Engineered with sturdy construction, the oven ensures consistent quality, while its suspended installation facilitates maintenance. Additionally, the induction heating reduces energy consumption, promoting sustainable production practices. This equipment supports production lines requiring high throughput and flexibility, making it invaluable for manufacturers seeking to diversify their product offerings efficiently.

Benefits

- Enhances production flexibility with customizable end-product designs, supporting diverse wafer stick varieties.

- Promotes sustainability with energy-efficient, emission-free induction heating technology.

- Streamlines operations with a user-friendly touch screen interface, reducing training time and errors.

- Ensures consistent product quality through sturdy construction and precise baking mechanisms.

- Integrates easily into existing production lines, allowing for scalable and adaptable manufacturing solutions.

- Applications

- Baked goods, Wafer products, Confectionery, Snacks

- End products

- Pressed wafer sticks, Two-colored wafer sticks, Wafer pillows, Filled wafer sticks, Fan-shaped wafer sticks

- Steps before

- Dough preparation, Extrusion, Shaping

- Steps after

- Filling, Decorating, Packing, Coating

- Input ingredients

- batter, sugar

- Output ingredients

- filled wafer sticks, two-colored sticks, wafer pillows, pressed sticks, fan-shaped sticks

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Heating Method

- Induction heating

- Automation

- Touch screen operated

- Sugar Content of Batter

- 40–70%

- Baking Ring

- Revolving heated baking ring

- Output Variation

- Filled sticks, two-colored sticks, wafer pillows, etc.

- Construction

- Steel ring, suspended installation

- Operation Principle

- Central touch screen

- Emissions

- Emission-free

- Energy Efficiency

- Sustainable production

- Customization Options

- Twisting and crimping add-ons

- Stick Formation

- Wrapped around mandrels

- Product Handling

- Aerated creams handling possible

- Automation level

- Centrally controlled via touch screen

- Batch vs. continuous operation

- Continuous operation

- Energy efficiency

- Emission-free induction heating

- Changeover time

- Rapid

- Flexible product variety

- Cleaning method

- Not specified

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design for space efficiency

- Discharge method

- Conveyor belt / Wafer stick elevator

- Control panel type

- Touch screen interface

- Heating system type

- Induction heating

- Structure material

- Steel ring construction

- Baking ring size

- Customizable

- Control panel type

- Touch screen

- Heating system

- Induction heating

- End product customization

- Various surfaces, twisting, crimping

- Add-on capabilities

- Filling device for cream and coatings

- Material handling

- Aerated creams