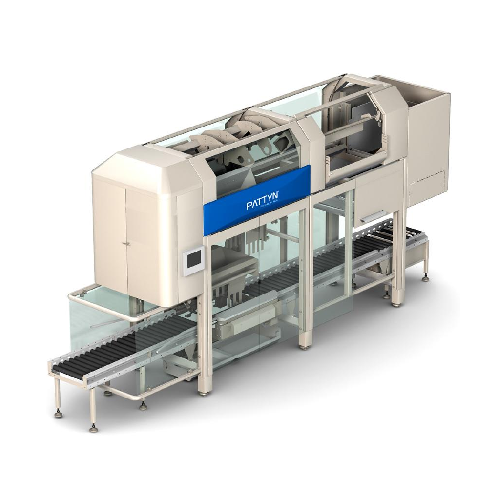

High-speed baguette case filling station

Effortlessly organize and pack bakery products into cases at high speed, ensuring product integrity and optimizing throughput with versatile adjustments for varying product sizes and types.

Packs and Organizes Bakery Products

The MEC-31 Case Filling Station, a solution from Pattyn Packaging Lines, is engineered for high-speed packing of bakery and pastry products. This specialized equipment efficiently organizes baguettes, artisan bread, and mini bakery items directly into cases. Capable of handling up to 60,000 small products per hour, the MEC-31 enhances productivity with its continuous operation. Featuring an open-frame design and automatic, unlockable top hoppers, it ensures both easy cleaning and safe accessibility for operators. It seamlessly integrates with existing production lines, especially when combined with Pattyn’s case erectors, bag inserters, and palletizers, creating a fully automated packaging system. With variations available for different production needs, the MEC-31 offers robust performance and adaptability, making it an ideal choice for bakery producers and food processing companies.

Benefits

- Enhances production efficiency with high-speed throughput, handling up to 60,000 small items per hour.

- Ensures reliable operation with trouble-free packing, even in cases with poor-quality materials.

- Facilitates easy maintenance through tool-free removable sections for swift cleaning.

- Maximizes operational safety and comfort with easily accessible hoppers and open-frame design.

- Increases production capacity with optional dual-machine setup for expanded output.

- Applications

- Pastry products, Baguettes, Half-baguettes, Small bakery items, Bakery products, Artisan bread

- End products

- Petit fours, Sourdough baguettes, Baguette bread loaves, Garlic or herb), Small croissants, Mini danishes, Flavored baguettes (e.g, Pastry rolls, Mini bread rolls, Artisan ciabatta loaves, Traditional french baguettes

- Steps before

- Mixing, Kneading, Baking, Cooling

- Steps after

- Sealing, Palletizing, Labeling, Distribution

- Input ingredients

- bakery products, pastry products, baguette style products, white baguettes, artisan baguettes, half-baguettes, small bakery products

- Output ingredients

- packed bakery products, packed pastry products, boxed baguettes, boxed half-baguettes, boxed small products

- Market info

- Pattyn is known for its expertise in designing and manufacturing industrial packaging solutions, specializing in ETO equipment for bulk packaging automation, with a strong reputation for innovation, quality, and customer-focused service in the industry.

- Capacity

- Up to 60, 000 small products/hour

- Capacity

- Up to 9, 000 baguettes/hour

- Capacity

- Up to 13, 000 half-baguettes/hour

- Output

- Up to 8 batches/min

- Automation

- Numerous automatic adjustments

- Cleaning method

- Tool-free removable section doors

- Configuration

- Standard and Artisan style versions

- Working mechanism

- Automated high-speed filling

- Batch vs. continuous operation

- Batch inline

- Changeover time

- Quick changeover with automatic adjustments

- Cleaning method

- Tool-free removable section doors

- Automation level

- High automation with PLC control

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Box

- Product type

- Bakery and pastry products

- Product speed

- Up to 60, 000 products/hour

- Machine footprint

- Compact open frame

- Access doors

- Wide access doors

- Hopper accessibility

- Unlockable top hoppers brought to operator level

- Removable section doors

- Tool-free removable section doors

- Configuration versions

- Standard (S), Artisan style (L)

- Machine configuration

- Standard / Artisan Style

- Double machine layout

- Yes / No

- Top hopper accessibility

- Automatic unlockable

- Frame type

- Open frame with wide access doors