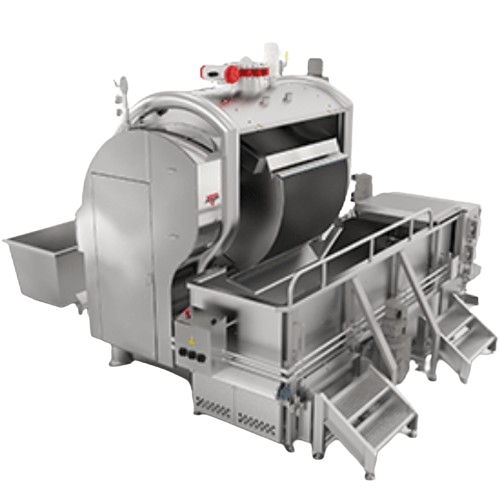

Industrial dough mixing system for bakeries

Enhance your bakery’s efficiency with a system that ensures precise dough mixing and seamless handling, ideal for producing consistent high-quality bread, pastry, and snack foods on an industrial scale.

Mixes, Ferments, and Distributes Industrial Dough

The AMF Fusion industrial dough mixing and handling system, engineered by AMF Bakery Systems, offers a comprehensive solution for high-capacity bakery operations. It features horizontal batch, Sigma Arm, and Triple Roller Bar Mixers to precisely mix a wide range of dough types, crucial for products such as whole grain bread, brioche buns, and gluten-free pizza crusts. The integration of automatic guided vehicles facilitates efficient dough transport while minimizing manual handling, enhancing both safety and workflow efficiency. With the ability to process at industrial scale, this system supports batch and high-speed operations, incorporating fermentation and dough distribution to streamline production for applications in bread, pastries, and snack foods. The equipment’s superior design ensures sanitary operation, backed by localized support for consistent performance and longevity, making it ideal for food production facilities seeking high efficiency and product uniformity.

Benefits

- Enhances production efficiency with seamless dough handling and mixing integration.

- Reduces manual labor through automated dough transportation using guided vehicles.

- Ensures consistent quality across a wide array of bakery products.

- Minimizes energy usage due to optimized motor controls.

- Provides customizable solutions to meet specific bakery production needs.

- Applications

- Cookies, Buns, Bread, Flatbreads, Snack foods, Pizza, English muffins, Crackers, Croissants, Rolls, Pastries, Bakery products, Pretzels, Artisan bread

- End products

- Gluten-free pizza crusts, Butter croissants, Sourdough rolls, Flatbreads with herbs, Chocolate chip cookies, Almond pastries, Whole grain bread, Salted pretzels, Cheese crackers, Ciabatta artisan bread, Whole wheat english muffins, Brioche buns

- Steps before

- Dough Preparation, Ingredient Weighing, Ingredient Mixing

- Steps after

- Dough Fermentation, Dough Proofing, Dough Baking, Cooling, Freezing, Slicing, Bagging

- Input ingredients

- dough, flour, water, yeast, baking ingredients

- Output ingredients

- soft panned or tin bread, soft buns and rolls, English muffins, artisan bread and rolls, pizza and flatbreads, pastries, croissants, snack foods, cookies, crackers, pretzels

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Mixing Capacity

- Up to 4, 000 lbs

- Control System

- Automated GPS

- Flexibility

- Multi-purpose mixing

- Operating Temperature

- Not specified

- Precision in Mixing

- High

- Cleaning Method

- Sanitary Design

- Automation Level

- Fully Automated

- Dough Transportation

- Automatic Guided Vehicle (AGV)

- Capacity Range

- Wide Range

- Construction Material

- Sanitary

- Installation Base

- 500+ installations worldwide

- Batch Size

- Not specified

- Working mechanism

- Horizontal batch mixing

- Integrated steps

- Dough handling and mixing

- CIP/SIP

- Sanitary design

- Batch vs. continuous operation

- Batch

- Automation level

- Fully automated

- Durability and performance

- High

- Flexibility

- Multi-purpose mixing

- Footprint

- Compact

- Machine Configuration

- Batch Mixer

- Mixing Arm Type

- Sigma Arm

- Mixing Arm Type

- Triple Roller Bar

- Discharge Method

- Automated Handling

- System Integration

- Fully Automated Dough Handling

- Internal Vehicle System

- Automatic Guided Vehicle (AGV)

- Max Capacity

- Up to 4, 000 lbs

- Control panel type

- Touchscreen HMI

- Integration possibilities

- AMFConnect™ for data-driven solutions

- Tilt system customization

- Innovative tilt for sigma arm mixers

- Automated handling options

- Automatic Guided Vehicle (AGV) for dough transport