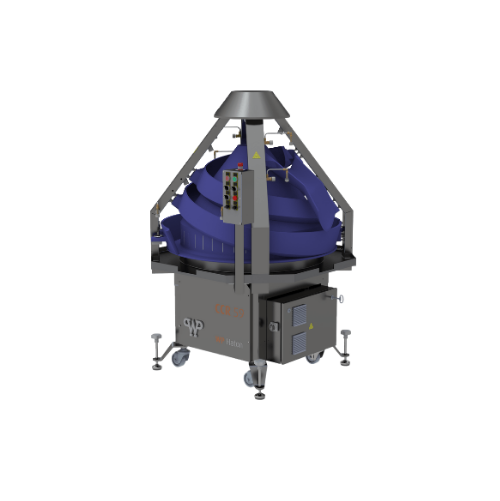

Adjustable conical dough rounder

Optimize your dough processing with a conical rounder that effortlessly handles high water content doughs, ensuring perfect separation and weight accuracy for a variety of bakery products.

Rounds and Separates Diverse Dough Types

The CR 59 AT Conical Dough Rounder from WP Haton is engineered to meet the demanding needs of bakeries and bread manufacturers. With its adjustable tracks, this rounder expertly processes a wide range of dough weights and types, from wheat to multigrain. Equipped with a Teflon-coated cone, it minimizes sticking, eliminating the need for flour, while the optional automated oiling system facilitates smooth handling of sticky doughs. Ideal for operations that require efficient dough rounding and separation in both manual and continuous batch processes, the CR 59 AT seamlessly integrates into existing production lines for enhanced product quality. Designed with the flexibility to handle doughs with high water content, it is a vital component for producing everything from artisan breads to pizza dough. Its robust construction ensures longevity and consistent performance, while the modular design supports easy upgrades. The rounder can be customized to fit specific operational needs, ensuring it complements your current production capabilities efficiently.

Benefits

- Enhances dough consistency and shape for superior end-product quality.

- Supports a wide range of dough types, increasing production versatility.

- Reduces labor and time with its automated oiling system for sticky doughs.

- Minimizes material waste with efficient dough separation and handling.

- Integrates seamlessly into existing production lines for streamlined operations.

- Applications

- Rye-based products, Bread, Wheat-based products, Bakery products, Multigrain products, Dough-based products

- End products

- Rye bread, Pizza dough, Sandwich loaves, Sourdough bread, Multigrain baguettes, Whole grain bread, Wheat rolls, Ciabatta, Rye rolls, Artisan bread

- Steps before

- Dough Dividing, Dough Weighing

- Steps after

- Proofing, Moulding

- Input ingredients

- wheat dough, wheat/rye dough, rye dough, multigrain dough, high water content dough

- Output ingredients

- rounded dough, smooth dough pieces, separated dough pieces

- Market info

- WP Haton is known for producing high-quality, industrial dough processing equipment. They specialize in designing and manufacturing custom engineered-to-order solutions for the baking industry, with a strong reputation for innovation, reliability, and customer service.

- Weight Range

- Wide, adjustable

- Material Type

- Wheat, Rye, Multigrain

- Automation

- Automated oiling system

- Stickiness Handling

- Teflon coated cone

- Flour Usage

- Not required

- Automation level

- Automated oiling system

- Changeover time

- Easy handling

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Teflon coated, no flour required

- Adaptability

- Adjustable tracks for a wide weight range

- Dough type compatibility

- Wheat, wheat/rye, rye, multigrain

- Water absorption handling

- High water content dough

- Sticky dough handling

- Automated oiling system for smooth throughput

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Dough type compatibility

- Wheat / Rye / Multigrain

- Dough water absorption level

- High

- Dough stickiness

- Handled with Teflon coated cone

- Weight range

- Wide

- Adjustment Type

- Adjustable tracks

- Adjustable tracks

- Suitable for wide weight range

- Cone material

- Teflon coated

- Discharge method

- On the outfeed side

- Shape

- Conical

- Automation

- Automated oiling system

- Adjustable tracks

- Wide weight range

- Automated oiling system

- Available for sticky dough types

- Teflon coated cone

- Prevents sticking without flour

- Dough type compatibility

- Wheat, Rye, Multigrain

- Dough absorption capacity

- High water absorption