Automatic oven loading and unloading system

Streamline your bakery’s production efficiency with precise and synchronized oven loading and unloading, ensuring consistent baking and reducing downtime.

Transfers and Synchronizes Baked Goods Efficiently

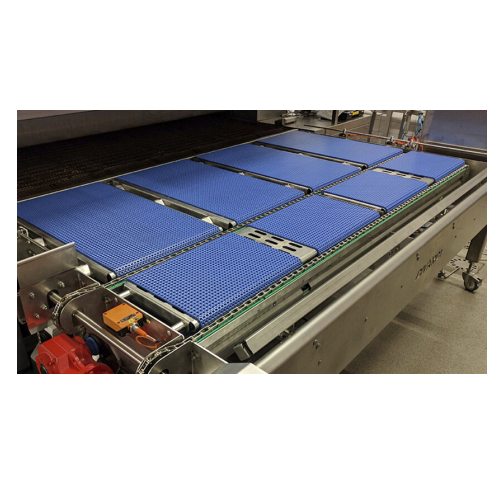

The Radilinq Oven Loading and Unloading System from Rademaker is designed to enhance the efficiency of industrial bakeries by ensuring seamless synchronization in transporting baked products to and from ovens. This system uniquely synchronizes each row of trays or pan-straps during loading and unloading, maintaining a continuous flow that prevents production bottlenecks. Applications range from sourdough bread and croissants to pastries and pizzas, making it versatile for various bakery products.

The system operates with high-speed automation, capable of integrating into existing production lines as standalone units or part of a modular setup. Constructed with robust and open designs, the equipment requires minimal maintenance, featuring chain-free, lubrication-free operation. Options include rollers or high-temperature resistant belts to meet specific production needs. With Radilinq, you benefit from customizable configurations and engineering support, all while optimizing floor space with elevated design solutions.

Benefits

- Enhances production line efficiency by seamlessly synchronizing tray movements, reducing bottlenecks.

- Minimizes maintenance demands with lubrication-free, chain-free design, saving on operational costs.

- Offers flexible integration options, either as standalone or within modular systems, for tailored production solutions.

- Conserves floor space with elevated design, optimizing facility layout.

- Adapts to various baking processes with customizable configurations, improving versatility.

- Applications

- Pie, Bread, Flatbreads, Laminated dough, Pizza, Croissants, Quiche, Pastries, Donuts

- End products

- Glazed donuts, Custard tart, Danish pastry, Pita bread, Chocolate donuts, Traditional pizza, Whole grain bread, Meat pie, Puff pastry, Multigrain bread, Sourdough bread, Focaccia, Margherita pizza, Cheese croissant, Chocolate croissant, Flaky pastry dough, Naan, Baguette, Brioche, Spinach and feta quiche

- Steps before

- Proofing, Conveying, Dough sheeting

- Steps after

- Depanning, Cooling, Packing

- Input ingredients

- baking trays, pan-straps

- Output ingredients

- loaded baking trays, loaded pan-straps, unloaded baking trays, unloaded pan-straps

- Market info

- Rademaker is known for its expertise in manufacturing industrial bakery equipment, offering engineered-to-order solutions. They have a strong reputation for innovative, high-quality machines designed for efficiency and reliability in food production.

- Automation

- PLC-controlled

- Loading and Unloading Speed

- Based on user demands

- Precision

- High Accuracy in Synchronization

- Movement

- Precise and synchronized

- Design

- Open and Robust

- Floor Space

- Elevated Design for Ample Space

- Belt Options

- Rollers or High-Temperature Resistant Belts

- Lubrication

- Chain-free Systems

- Configuration

- Stationary or Movable

- Integration

- Standalone or Integrated

- Working mechanism

- Automatic loading/unloading

- Integrated steps

- Loading and unloading synchronization

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Easy maintenance

- Flexibility

- Stationary or movable configurations

- Abrasion resistance

- High durability materials

- Cleanability

- Stainless steel surfaces

- Corrosive resistance (e.g. acids)

- Corrosion-resistant alloys

- High-temperature resistance

- High-temp resistant belts

- Footprint

- Compact/Open

- Design

- Robust/Elevated

- Floor Space

- Ample

- Construction Material

- High-Temperature Resistant Components

- Configuration

- Stationary/Movable

- System Type

- Standalone/Integrated

- Loading/Unloading Method

- Rollers/Belts

- Chain

- Chain-free

- Control panel type

- Integrated HMI/PLC

- System configuration

- Standalone or integrated line

- Loading and unloading configuration

- Stationary or movable units

- Material handling option

- Rollers or high-temperature resistant belts

- Design flexibility

- Open, robust design

- Space optimization

- Elevated design for ample floor space

- Lubrication requirement

- Chain-free systems