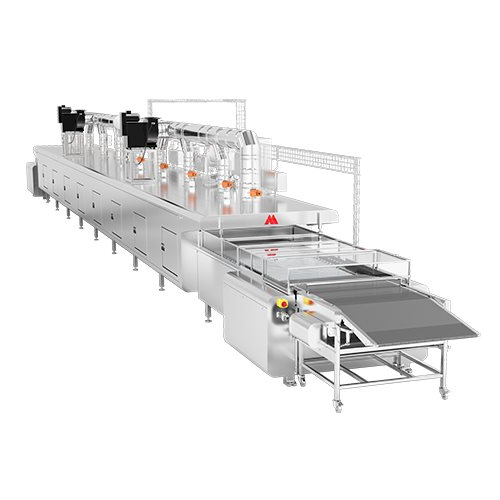

Direct gas fired oven for biscuit and cracker production

Achieve consistent, energy-efficient baking for a wide range of products with this direct gas fired oven, designed to deliver precise temperature control and uniform heating throughout each baking zone.

Bakes and Heats Biscuits, Cookies, and Confectionery

The Conny™ Direct Gas Fired Baking Oven from Aasted is engineered for industrial bakeries and chocolate manufacturers seeking consistent quality and energy efficiency. With gas burners strategically placed within the oven, it offers precise temperature control and rapid heating. This system is ideal for baking a variety of products, including hard biscuits, crackers, and chocolate-coated confections. Its modular design allows for handling belt widths from 800 to 1500 mm and streamlined installation with preassembled sections. Integrated with a zero gas pressure system, the oven ensures optimal gas and air mixture for each zone, enhancing energy savings by up to 80%. Additionally, the interior utilizes CorTen steel for durability against corrosion, with large hinged doors for easy cleaning and maintenance. The oven’s design supports continuous, high-speed operations, essential for scalable production.

Benefits

- Achieves uniform baking with precise temperature control and gas distribution.

- Minimizes energy costs with up to 80% savings through efficient burner systems.

- Reduces installation time with preassembled sections.

- Enhances durability and maintenance ease with corrosion-resistant materials.

- Supports high-speed production with continuous operation capability.

- Applications

- Cookies, Biscuits, Confectionery, Crackers, Bakery products, Chocolate

- End products

- Oatmeal cookies, Chocolates with inclusions, Sugar biscuits, Chocolate chip cookies, Chocolate-coated confectionery, Saltine crackers, Pastries, Cheese crackers, Hard biscuits, Sponge cakes

- Steps before

- Ingredient Mixing, Dough Preparation, Feeder Mixer

- Steps after

- Cooling, Packaging, Chocolate Coating, Quality Control

- Input ingredients

- gas, air, chocolate mass, ingredients for hard biscuits, ingredients for crackers, ingredients for cookies

- Output ingredients

- baked hard biscuits, baked crackers, baked cookies, baked products with perfect crust, reduced energy consumption products

- Market info

- Aasted is known for its expertise in manufacturing equipment for the chocolate, bakery, and confectionery industries, offering solutions like tempering, molding, and baking machinery with a strong reputation for innovation and quality.

- Belt Width

- 800–1500 mm

- Heating Type

- Direct Gas Fired / Electric

- Energy Consumption

- Low

- Section Length

- 2 m preassembled sections

- Capacity

- Up to 2½ tons/hr (Filling, Weighing St.)

- Melting Tank Capacity

- 150 kg to 3, 000 kg

- Speed Control

- High pressure fan with speed control

- Gas Pressure System

- Zero gas pressure system

- Temperature Control

- Correct mixture of gas and air

- Baking Method Flexibility

- Variety of baking methods

- Working mechanism

- Direct gas-fired

- Heating method

- Direct gas burners

- Automation level

- PLC Control

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Energy efficiency

- Fast heating, low energy

- Burner control system

- Central distribution

- Temperature control

- Individual zone control

- Air incorporation control

- High pressure fan

- Cleaning access

- Hinged cleaning door

- Corrosion resistance

- CorTen steel, stainless steel

- Cleanability

- Enameled steel, stainless steel

- Temperature tolerance

- High temperature baking

- Heat Sensitivity

- Yes

- Viscosity of Material

- Low to High

- Material Compatibility

- Corrosive resistance (e.g. acids)

- Size and Shape

- Hard Biscuits, Crackers, Cookies

- Machine footprint

- 2m preassembled sections

- Belt width

- 800 – 1500mm

- Tank capacity

- 150 kg to 3, 000 kg

- Material

- Corrosion resistant steel/CorTen

- Control panel type

- Available with PLC/SCADA integration

- Heating method

- Direct Gas or Electric

- Section length

- 2m preassembled sections

- Belt width

- 800–1500 mm

- Material of construction

- CorTen and Stainless Steel

- Cleaning access

- Hinged doors

- Burner control system

- Gas/air mix injection with speed control