Thermoforming solution for flexible or rigid packaging

Optimize your packaging efficiency with a high-performance thermoforming machine, engineered for seamless integration with your production line, enabling precise vacuum sealing and modified atmosphere packaging to ensure product quality and extend shelf life.

Thermoforms and Packages Solid Products

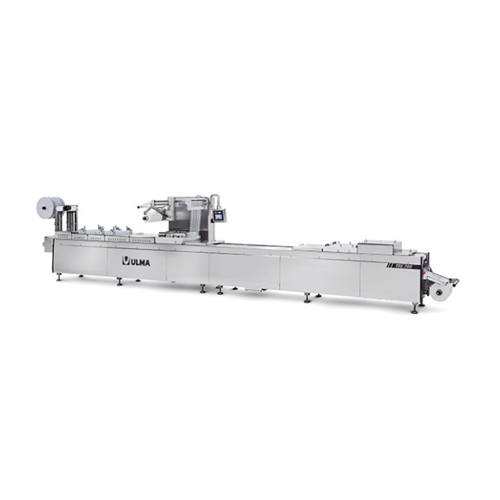

The TFE 700 from ULMA Packaging is a high-performance thermoforming machine designed for both food and non-food packaging applications. It excels in creating modified atmosphere packages (MAP) and vacuum-sealed products, utilizing flexible or rigid films. With its modular construction and corrosion-resistant stainless steel frame, the TFE 700 ensures durability and adaptability for various production requirements. The machine is suitable for packaging sliced ham, packaged lettuce, frozen chicken breasts, sterile syringes, croissants, chocolate chip cookies, and hard candies, providing significant versatility.

Equipped with a user-friendly 7″ color touch screen UPC control system, the TFE 700 supports multi-language capabilities and remote control access, making it easy to integrate into your existing production line. The machine operates at high speed with continuous automation, optimizing cycle time through real-time monitoring. It includes options for dosing systems, product loading, coding and printing, and metal detection, ensuring comprehensive packaging solutions tailored to your needs.

Constructed to meet EC safety standards, the TFE 700 offers integrated maintenance programs and remote support management for minimized downtime. Its original top-level commercial components and ease of integration make it an ideal choice for food packaging companies, medical product manufacturers, meat processing industries, bakery and confectionery producers, and poultry processing industries seeking reliable and efficient packaging solutions.

Benefits

- Ensures product longevity and freshness with MAP and vacuum sealing capabilities.

- Enhances operational efficiency through continuous, high-speed automation.

- Provides versatile packaging solutions for diverse industries, from food to medical products.

- Minimizes maintenance downtime with integrated remote support and easy-access design.

- Adapts to production needs with modular construction and customizable options.

- Applications

- Biscuits, Bakery, Meat, Confectionery, Medical products, Produce, Poultry

- End products

- Sterile syringes, Chocolate chip cookies, Hard candies, Frozen chicken breasts, Croissants, Sliced ham, Packaged lettuce

- Steps before

- Product Loading, Dosing

- Steps after

- Pack Converging, Coding and Printing, Seal Testing, Metal Detection, Integration in End of Line

- Input ingredients

- flexible film, rigid film, food products, non-food products, medical products

- Output ingredients

- vacuum packages, modified atmosphere packages, flexible packaging, rigid packaging

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Construction Material

- Stainless steel

- Control System

- UPC control system

- Display Type

- 7" colour touch screen

- Language Support

- Multi-language with Cyrillic, Arabic, Katakana

- Network Connectivity

- Ethernet

- Security Backup

- Pendrive (USB)

- Remote Control

- Ethernet interface

- Pack Options

- Flexible and rigid packaging

- Vacuum Options

- Yes, optional vacuum and gas flushing systems

- Cycle Optimization

- Tools based on time monitoring

- Maintenance Level

- Minimum maintenance required

- Support Management

- Remote Support Management (RSM)

- Automation

- High operational reliability

- Adaptability

- Modular construction

- Safety Standard

- EC regulations

- Material Resistance

- Corrosion resistant materials

- Working mechanism

- Thermoforming with MAP and vacuum options

- Integration

- Optional vacuum and gas flushing systems

- Automation level

- PLC-controlled, Remote control via HMI

- Changeover time

- Easy format change

- Modularity

- Modular construction, adaptable to project needs

- Control interface

- UPC control system with 7" colour touch screen

- Permission levels

- Access protection with 3 levels

- Remote operations

- Remote view and control system

- Safety

- Safety standard according to "EC" regulations

- CIP/SIP

- Minimum maintenance with maintenance program integrated

- Cycle optimization

- Cycle optimization tools based on time monitoring of stations

- Expansion capability

- Machine enlargement depending on project

- Corrosion resistance

- Stainless steel

- Packaging type

- Modified atmosphere packaging (MAP)

- Product suitability

- Food and non-food products

- Machine footprint

- Modular construction

- Material used

- Stainless steel

- Frame

- Stainless steel frame

- Structure

- Corrosion resistant materials

- Customizability

- Modular machine, adaptable to different formats

- Accessibility

- Removable lateral covers

- Machine expansion

- Can be enlarged depending on the project

- Optional components

- Additional dies available

- Control panel

- 7" colour touch screen display

- Modular construction

- Can be enlarged based on project

- Control panel type

- 7" colour touch screen display

- Format change

- Easy

- Remote control and update

- Ethernet interface, USB updates

- Integration possibilities

- Remote Support Management via Ethernet

- Machine adaptations

- Special adaptations for medical products

- Optional components

- Optional additional dies