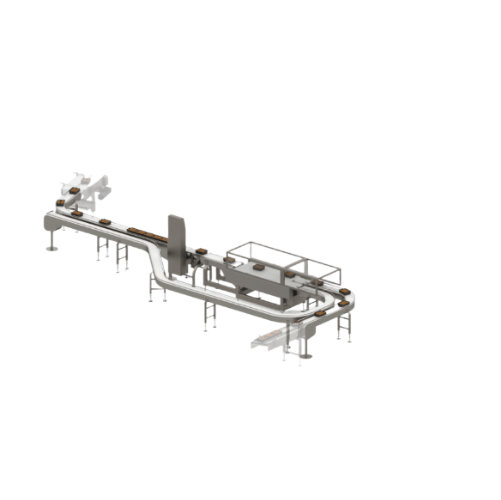

Tray weight inspection system

Ensure accurate and efficient quality control by seamlessly integrating a high-speed tray weight inspection system to identify and sort underweight or overweight trays in your production line.

Inspects and Sorts Tray Weights

The Tray Weight Inspection system from Royal Houdijk is designed to enhance efficiency in food processing, packaging plants, and industrial manufacturing facilities by ensuring accurate tray weight adherence. This system specializes in weighing, inspecting, and sorting trays to maintain consistency in pre-packaged meals, confectionery, and electronic component packaging. Operated continuously at high speeds, it utilizes a check weigher equipped with a tray re-work loop to separate trays that fall outside weight specifications. Integrated seamlessly into packaging operations, it enables real-time corrections, minimizing downtime. Featuring PLC controls, it supports automated processes and remote monitoring, reducing labor costs and improving accuracy. Suited for solid products, it operates using energy-efficient technology, promoting sustainability in high-throughput environments.

Benefits

- Ensures consistent product quality by accurately managing tray weight deviations.

- Increases operational efficiency with continuous high-speed sorting.

- Minimizes waste and reduces rework through precise weight inspection.

- Facilitates seamless integration into existing production lines with PLC controls.

- Promotes sustainability with energy-efficient operation.

- Applications

- Trays, Industrial components, Food products, Packaged goods

- End products

- Hardware packaging trays, Industrial machinery parts trays, Snack food trays, Medical equipment trays, Assembly line parts trays, Electronic component trays, Pre-packaged meals, Confectionery trays, Frozen food packages

- Steps before

- Tray Loading, Weighing Preparation

- Steps after

- Tray Rework, Weight Correction, Quality Assurance, Packaging

- Input ingredients

- trays

- Output ingredients

- underweight trays, overweight trays, tray re-work

- Market info

- Houdijk is known for designing and manufacturing advanced handling and processing equipment for the biscuit and bakery industry, specializing in automated systems to improve efficiency and maintain product quality.

- Accuracy

- Check weigher

- Automation

- Tray re-work loop

- Working mechanism

- Check weigher

- Integrated steps

- Tray re-work loop

- Batch vs inline flow

- Inline, with tray re-work loop

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tray Material Compatibility

- Plastic/Metal

- Discharge method

- Tray re-work loop

- Control panel type

- Touchscreen / Button-based

- Integration possibilities

- PLC / SCADA systems

- Tray re-work loop

- Configurable / Extendable

- Weight threshold setting

- Adjustable

- Discharge options

- Automatic / Manual