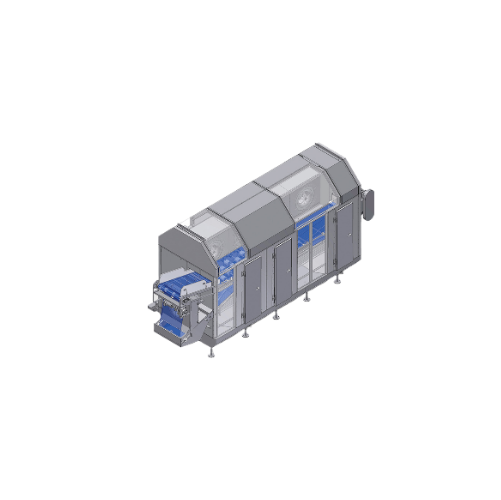

Industrial tunnel freezer for individual quick freezing (iqf)

Achieve precise temperature control and prevent product damage during freezing and chilling processes with an engineered solution designed to handle diverse applications—from frozen foods to vegan alternatives—ensuring quality and consistency in every batch.

Freezes and Chills Foods Continuously and Efficiently

The GEE IQF Tunnel Freezer is designed by GEA, offering a flexible and integrated solution for high-demand food processing environments. Utilizing precise individual quick freezing technology, it prevents product clumping and deformation, ensuring superior quality for diverse products like frozen peas, vegan burgers, and seafood. With a continuous operation capability, it handles varying throughputs efficiently, supporting high-speed processing lines across the food and beverage industries. The system integrates seamlessly with existing pre-cooling, freezing, and chilling lines, equipped with energy-efficient motors to reduce consumption. Built with robust materials, it ensures longevity and corrosion resistance, while compliance with food safety standards guarantees reliable operation and peace of mind for food producers.

Benefits

- Ensures product integrity by minimizing breakage and over-freezing damage.

- Enhances operational efficiency with continuous high-speed processing.

- Reduces energy costs due to optimized motor controls.

- Seamlessly integrates into existing production lines for streamlined operation.

- Complies with industry safety standards for reliable and safe food processing.

- Applications

- Seafood, Meat products, Fruits and vegetables, Pre-cooked meals, Vegan alternatives, Chilled foods, Frozen foods, Bakery products, Dairy products

- End products

- Frozen beef patties, Vegan burgers, Frozen shrimp, Chilled chicken breasts, Frozen pizza bases, Ice cream bars, Frozen peas, Frozen berries, Pre-cooked lasagna

- Steps before

- Pre-cooling, Retrograding

- Steps after

- Finish-freezing, After-glaze hardening

- Input ingredients

- hollow and soft products, ripe products

- Output ingredients

- frozen products, chilled products, finish-frozen products, after-glaze hardened products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Integration

- Pre-cooling, retrograding, freezing, chilling, finish-freezing, after-glaze hardening

- Handling

- Hollow, soft, sensitive, flexible, avoid over-freezing

- Capacity

- Flexible for wide range of product types

- Working mechanism

- IQF Tunnel Freezer

- Integrated steps

- Pre-cooling, Retrograding, Freezing, Chilling, Finish-Freezing, After-Glaze Hardening

- Automation level

- Configured for flexible handling of applications

- Cleaning method

- Hygiene and gentle handling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Feed method

- Flexible product handling

- Discharge method

- Gentle product handling

- Control panel type

- Digital interface

- Integration capability

- Processing line integration

- Handling capability

- Hollow and soft, cracked, damaged prevention