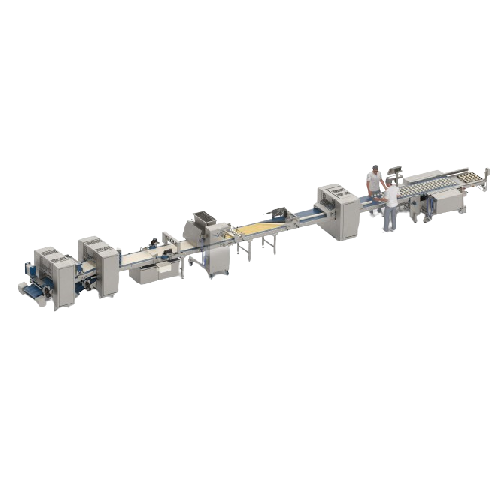

Pastry production line for large-scale bakeries

Streamline your bakery production with a versatile line designed to efficiently shape, fill, and decorate a broad range of pastries, ensuring consistent quality and maximizing your product variety while reducing manual labor and changeover time.

Shapes, Rolls, and Decorates Pastry Products

The Radini pastry make-up line from Rademaker offers a comprehensive solution for bakeries looking to enhance product variety while optimizing the efficiency of pastry production. This semi-automatic system is designed for shaping, rolling, folding, braiding, and decorating a wide range of bakery products including croissants, pain au chocolat, and almond pockets. Utilizing a user-friendly interface, it allows for easy operation and quick changeovers, handling up to 1,000 kg of dough per hour with a working width of 600 or 800 mm. With automation capabilities, it integrates seamlessly into existing production lines, offering both semi-automatic and fully automatic operations. The equipment can accommodate various types of products, from solid pastries to slurry-filled options, and includes features such as a variable-speed motor for energy efficiency and flexible customization options for different dough types. Designed with hygiene in mind, it supports quick, hassle-free cleaning to reduce downtime and ensure consistent quality production.

Benefits

- Enhances production efficiency by handling diverse pastries on the same line.

- Reduces changeover time with quick and easy tool adjustments.

- Minimizes labor requirements through automated shaping and decorating processes.

- Ensures consistent product quality with precise control over shaping and filling.

- Supports flexible production with scalable options from semi to fully automated operations.

- Applications

- Pie, Buns, Bread, Flatbreads, Laminated dough, Pizza, Croissants, Quiche, Donuts, Pastries

- End products

- Pain au chocolat, Double-layered pastries, Maple pecan braids, Book folds, Sausage rolls, Cinnamon rolls, Butterflies-shaped pastries, Triangular pastries, D-shape pastries, Almond pockets

- Steps before

- Dough preparation, Proofing, Laminating

- Steps after

- Baking, Cooling, Packaging

- Input ingredients

- dough, filled dough sheet, fillings, toppings

- Output ingredients

- pastries, croissants, folded products, rolled products, braided products, books folds, rectangular pockets, almond pockets, pain au chocolate, D-shape, triangles, sausage rolls, swirls, cinnamon rolls, butterfly-shaped pastry, maple pecan pastry

- Market info

- Rademaker is known for its expertise in manufacturing industrial bakery equipment, offering engineered-to-order solutions. They have a strong reputation for innovative, high-quality machines designed for efficiency and reliability in food production.

- Working width

- 600 or 800 mm

- Capacity

- up to 1, 000 kg dough per hour

- Product output

- Circa 14, 000 folded products on 5 rows per hour

- Croissant output

- Circa 7, 200 croissants on 3 rows per hour

- Automation

- Manual / Automated process steps

- Shaping methods

- Rolling, folding, braiding, cutting

- Filling options

- Automated / Manual

- Fill weight accuracy

- High weight accuracy

- Topping options

- Automated / Manual strewing

- Working mechanism

- Fully/Semi-automated

- Integrated steps

- Shaping, Folding, Filling, Decorating

- Changeover time

- Fast and easy

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Fully wet cleanable

- Automation level

- Semi-automatic to Fully automatic

- Cleanability

- Fully wet cleanable

- Machine footprint

- Compact design

- Working width

- 600 or 800 mm

- Control panel type

- User-friendly machine interface

- Capacity

- Up to 1, 000 kg dough per hour

- Product output

- Circa 14, 000 folded products per hour

- Product output

- Circa 7, 200 croissants per hour

- Tool changeover

- Fast and easy

- Mobile execution

- Available for croissant module

- Control panel type

- User-friendly machine interface

- Tooling flexibility

- Easy to place and remove tools

- Changeover time

- Fast and easy