Industrial dough rounder for high-capacity production lines

Optimize your bakery’s efficiency by integrating a high-capacity dough rounder designed to handle various dough types, ensuring consistent shaping for artisanal breads and rolls.

Processes and Rounds Diverse Dough Types

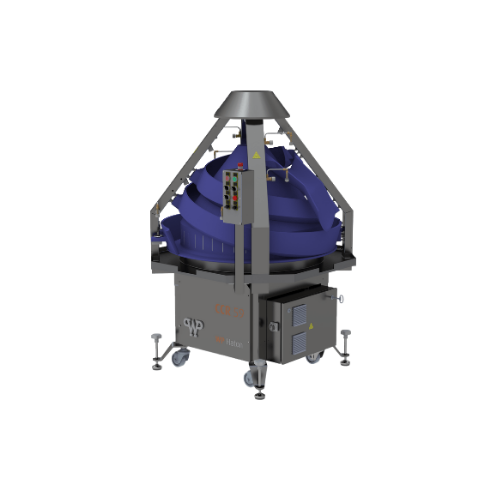

The CCR 69 AT Industrial Rounder from WP Haton is designed specifically for high-volume bread and bakery operations seeking efficient dough processing. This conical dough rounder excels in rounding both stiff and soft wheat and rye dough types, making it versatile for producing products such as bagels, baguettes, ciabatta, and artisan bread. Capable of handling up to 10,000 pieces per hour, it integrates seamlessly into high-capacity production lines, facilitating continuous operations with minimal downtime.

Its robust construction includes adjustable cone speed and longer tracks, ensuring precise shaping while minimizing the risk of dough pieces merging. The large-diameter cone provides ample distance between dough pieces, enhancing uniformity and quality. The equipment is PLC-controlled, offering easy integration into automated lines with options for remote monitoring. Designed for industrial baking conditions, it supports a range of dough compositions and is available with customization options to meet specific operational requirements. The CCR 69 AT also emphasizes time efficiency and ease of maintenance, streamlining your production processes for optimal productivity.

Benefits

- Maximizes production efficiency by processing up to 10,000 dough pieces per hour.

- Ensures consistent product quality with precise rounding, reducing rework and waste.

- Enhances production line flexibility by accommodating a variety of dough types and products.

- Reduces labor intervention with easy-to-adjust cone speed and track lengths.

- Streamlines integration into existing systems with PLC-controlled operations for seamless automation.

- Applications

- Bread, Wheat dough, Dough processing, Rye dough, Bakery products

- End products

- Baguettes, Rye bread, Sandwich loaves, Sourdough bread, Soft rolls, Bagels, Hard rolls, Ciabatta, Artisan bread, Focaccia

- Steps before

- Dividing, Proofing, Moulding

- Steps after

- Proofing, Moulding, Packing

- Input ingredients

- stiff wheat dough, soft wheat dough, wheat/rye dough

- Output ingredients

- rounded dough pieces

- Market info

- WP Haton is known for producing high-quality, industrial dough processing equipment. They specialize in designing and manufacturing custom engineered-to-order solutions for the baking industry, with a strong reputation for innovation, reliability, and customer service.

- Capacity

- Up to 10, 000 pcs/h

- Adjustable Cone Speed

- Yes

- Track Adjustability

- Adjustable tracks

- Dough Compatibility

- Stiff, soft wheat, wheat/rye

- Construction

- Robust

- Capacity

- Up to 10, 000 pcs/h

- Adjustable cone speed

- Adjustable

- Adjustable tracks

- Adjustable

- Operating flexibility

- Handles stiff and soft dough

- Rounding path

- Proven successful design

- Dough type compatibility

- Wheat and wheat/rye

- Distance control between dough pieces

- Large cone diameter

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Adaptable for various dough types

- Footprint

- Compact

- Shape

- Cylindrical Conical

- Diameter

- Large

- Discharge method

- Adjustable tracks

- Adjustable cone speed

- Yes

- Adjustable tracks

- Yes

- Capacity

- Up to 10, 000 pcs/h

- Robust construction

- Yes