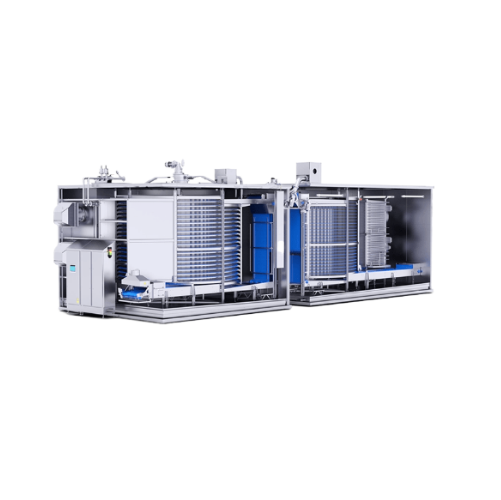

Spiral pasteurization system for packaged foods

Enhance product durability and quality with a compact spiral pasteurization system, optimizing heat and cooling processes for minimal germ presence in packaged foods.

Pasteurizes and Cools Packaged Foods Efficiently

The alco Spiral Pasto ASW from alco food-machines is a versatile pasteurizer and cooler designed for efficient thermal processing of packaged foods across multiple industries, including bakery, confectionery, poultry, meat, seafood, and plant-based proteins. This space-saving system uses spiral technology to conduct precise pasteurization and cooling processes. It features a dual-zone operation with separate heating and cooling areas, where products like sausages, tortellini, and plant-based patties are swiftly heated to eliminate harmful microorganisms and then cooled to enhance shelf life.

The machine supports a variety of packaging types and sizes, maintaining product integrity through gentle and uniform heating, aided by nozzle bars that ensure even water distribution. Its adjustable spiral belt guide allows for flexible assembly in diverse production environments while accommodating high-speed, continuous operations. Electrical, thermal oil, or steam-powered heating options are available, with dehumidification systems to optimize atmospheric conditions.

The alco Spiral Pasto ASW integrates seamlessly with existing lines, offering PLC control for automation and customization, and is designed for easy cleaning and maintenance with hinged ventilators and optional belt drying systems. This equipment is ideal for food manufacturers seeking to improve product quality and longevity while optimizing energy consumption.

Benefits

- Enhances product shelf life and safety by ensuring thorough pasteurization of packaged foods.

- Saves space and integrates easily into existing production lines with its compact spiral design.

- Increases energy efficiency through customizable heating options and reduced energy consumption.

- Offers flexible processing capabilities for various packaging sizes and product types.

- Simplifies maintenance and improves hygiene with easy access for cleaning and dehumidification systems.

- Applications

- Seafood, Ready meals, Pasta, Bread, Bakery, Confectionery, Meat, Plant-based protein, Poultry

- End products

- Lasagna, Bread rolls, Filled pastries, Ready-to-eat curry, Ravioli, Instant noodle packs, Tofu blocks, Tortellini, Plant-based burger patties, Shrimp dumplings, Nuremberg sausages, Packaged chicken breast, Marinated fish fillets

- Steps before

- Grinding, Mixing, Portioning, Packaging

- Steps after

- Cooling, Packing, Labelling, Distribution

- Input ingredients

- packaged products, foil bags of various sizes, Nuremberg sausages, ready meals, tortellini

- Output ingredients

- pasteurized products, germ-free products, durable food products

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Heating Method

- Direct and/or indirect steam-heated systems

- Temperature Regulation

- Continuously adjustable

- Cooling Areas

- Multiple, integrated into cooling line

- System Type

- Spiral technology with separate heating and cooling areas

- Heating Registers

- Electrical, thermal oil, or steam-powered registers

- Hygiene Design

- Hinged ventilators for heating register access, dehumidifying systems, optional belt drying/sterilization

- Water System

- Hot water sprinkler system for pasteurization

- Ventilation

- Hinged ventilators

- Dehumidifying System

- Uses exhaust air, condensation, and absorption

- Belt System

- Spiral belt guide with flexible, adjustable levels

- Nozzle Bars

- Even sprinkling with hot or cold water

- Space Efficiency

- Space-saving assembly of the spiral system

- Adjustability

- Free space between spiral levels can be adjusted variably

- Working mechanism

- Spiral technology

- Process type

- Pasteurization and cooling

- Flexibility

- Adjustable spiral belt guide

- Automation level

- Continuously adjustable temperature

- Energy efficiency

- Energy-efficient cooling areas

- Heating method

- Direct and/or indirect steam-heated

- CIP/SIP

- CIP principles suggested

- Batch vs. continuous operation

- Continuous operation

- Cleaning method

- Nozzle bars for sprinkling

- Temperature regulation

- Continuously adjustable

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact / Space-saving

- Discharge method

- Spiral belt guide

- Cooling areas

- Multiple / Flexible integration

- Spiral belt levels

- Selectable gap / Adjustable

- Assembly

- Space-saving / Flexible

- Control panel type

- Selectable gap between spiral levels

- Integration possibilities

- Multiple spirals in one machine

- Heating method

- Electrical, thermal oil, or steam-powered registers

- Cooling areas

- Multiple, adjustable

- Nozzle bar configuration

- Direct and/or indirect steam

- Sterilization enhancements

- Optional belt drying/sterilization