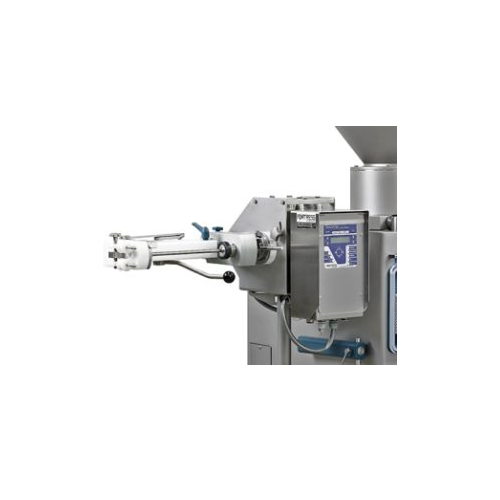

Metal detection system for twisted sausages production

Ensure the safety of your twisted sausage production line by detecting and removing metal contaminants efficiently before they compromise product quality.

Detects Metal Contaminants in Sausage Production

The Metal Detection System on Twister by Risco is a critical component in ensuring the safety and integrity of your meat processing operations. Positioned between the vacuum filler and automatic twister, this system rapidly detects metal contaminants in continuous sausage production, including bratwurst, frankfurters, and pork sausages. Operating with sonic and visual alerts, it integrates seamlessly into existing lines and meets CE standards, guaranteeing compliance and enhancing product safety. The system is easily connected via a fast connection system, ensuring minimal downtime during installation or maintenance. Constructed with durable materials suitable for food environments, it offers reliability and peace of mind for processors targeting stringent food safety regulations.

Benefits

- Enhances food safety by preventing metal contamination in meat products.

- Minimizes production interruptions with quick connection and integration into existing lines.

- Complies with CE standards, ensuring regulatory adherence and customer trust.

- Increases operational efficiency with continuous automatic detection.

- Delivers real-time alerts, reducing waste and safeguarding product quality.

- Applications

- Pet food, Bakery, Mortadella, Ham, Wurstel, Fruit and vegetables, Hot dogs, Ground meat, Sausages, Dairy products, Fish

- End products

- Cod portions, Mortadella bologna, Pork sausages, Bratwurst, Cheese blocks, Salmon fillets, Dog food pouches, Mortadella with pistachios, Diced carrots, Bologna, Croissants, Brined ham, Minced beef patties, Canned peaches, Burger buns, Smoked ham, Yogurt containers, Bockwurst, Frankfurters, Prosciutto, Cat food sachets

- Steps before

- Vacuum filling, Twistlinking

- Steps after

- Packaging, Quality control

- Input ingredients

- twisted sausages, sausages, hot dogs, wurstel

- Output ingredients

- metal-free sausages, detected metal contaminants

- Market info

- Risco is known for manufacturing industrial equipment, particularly for meat processing and food production. They specialize in innovative vacuum fillers, portioning systems, and stuffing machines, recognized for quality, reliability, and advanced technology in the food processing industry.

- Metal detection

- Sonic and visual detection

- Positioning

- Between vacuum filler outlet and twister

- Connection type

- Fast connection system

- Safety standard

- Conforms to CE standards

- Product compatibility

- Sausages, hot dogs, wurstel

- Detection mechanism

- Metal detection

- Connection system

- Fast connection

- Automation level

- Integrated with automatic twister

- Batch vs. continuous operation

- Continuous inline detection

- Security features

- Total security in production

- Alert Systems

- Sonic and visual alerts

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CE marking

- Yes

- Discharge method

- Fast connection system

- Control panel type

- Sonic and visual detection