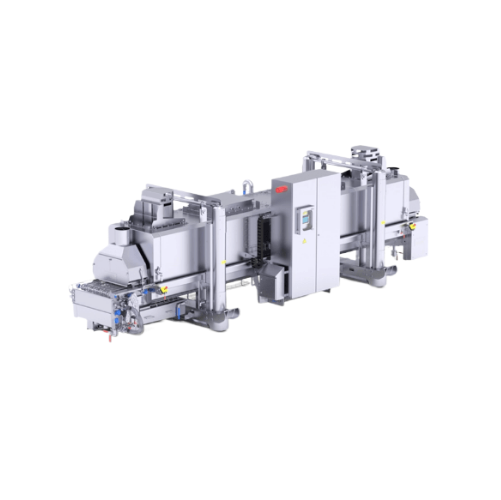

Linear convection oven for food processing

Achieve precise cooking and browning of diverse food products simultaneously while minimizing energy consumption with this dual-area convection oven, designed for optimal moisture control and consistent results.

Cooks and Browns with Precision

The alco Linear Convection Oven – AGU offers precision cooking with its unique dual-area system, allowing simultaneous heating and browning at varying temperatures. This industrial oven caters to bakery, pet food, and protein manufacturers, efficiently processing products like whole chicken, plant-based patties, and confectionery treats. It features top-performance heating elements powered by either electrical or thermal oil, handling different climate zones for optimal energy use and moisture control. With integrated PLC automation, this oven ensures seamless operation and is equipped with a Clean-in-Place (CIP) system for effortless maintenance. Built to your specific capacity, footprint, and application needs, this convection oven supports continuous processing with customizable configurations.

Benefits

- Optimizes product consistency with precise temperature control and targeted airflow.

- Minimizes energy costs through dual-area heating and moisture management.

- Enhances product quality by preventing moisture loss during cooking.

- Facilitates rapid production changeovers with CIP system for easy cleaning.

- Supports operational efficiency with customizable features for varied product sizes.

- Applications

- Seafood, Ready meals, Pet food, Bakery, Confectionery, Meat, Plant-based protein, Poultry

- End products

- Chicken nuggets, Lasagna, Dog kibble, Cat treats, Plant-based sausage links, Bacon strips, Seafood medley, Vegetarian lasagna, Beef burgers, Plant-based chicken patties, Meatloaf, Whole chicken, Pretzels, Fish sticks

- Steps before

- Portioning, Forming, Injection, Marination, Preparation

- Steps after

- Cooling, Freezing, Slicing, Packaging, Labeling

- Input ingredients

- whole chicken, burgers, nuggets, fish sticks, bacon, lasagna, pretzels

- Output ingredients

- cooked chicken, cooked burgers, cooked nuggets, cooked fish sticks, cooked bacon, cooked lasagna, browned pretzels

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Heating elements

- Electrical/Thermal oil

- Climate zones

- Up to 2

- Temperature control

- Precise, adjustable

- Cooking method

- Steam/Elevated temperature

- Capacity

- Customizable

- Belt cleaning

- Continuous with water spray, brushes

- Moisture control

- Dew point control system

- Cleaning system

- Integrated CIP

- Product size

- Accommodates different sizes

- Cooking consistency

- Hot circulating air/steam

- Dual-area system

- Yes

- Heating areas

- Separately adjustable

- Cooking method

- Hot circulating air / Steam

- Temperature control

- Precise control for repeatable results

- Airflow control

- Targeted for uniform heat transfer

- Steam cooking

- Available

- Indirect heat

- Eliminates by-products of combustion

- CIP Clean-in-Place system

- Integrated

- Custom-built

- Capacity, footprint, application requirements

- Dew point control

- Consistent and adjustable climate

- Belt wash system

- Rotating brushes and water spray lances

- Lecithin soak

- Minimizes product adhesions

- Cleanability

- Integrated CIP Clean-in-Place system

- Heat sensitivity

- Adjustable temperature zones

- Product adhesion

- Lecithin soak minimizes adhesion

- Machine footprint

- Custom built to meet exact capacity and application requirements

- Heating areas

- Dual-area system, separately adjustable

- Heating method

- Electrical and thermal oil-powered heating elements

- Belts

- Continuous with automatic cleaning system

- Control panel type

- Customizable for exact capacity and application needs