Flow wrapper for biscuits in stacks

Optimize your biscuit packaging with a flow wrapper designed to efficiently portion and wrap dry and flat biscuits in stacks, ensuring consistent product quality while accommodating various production needs.

Portions and Wraps Biscuits in Stacks

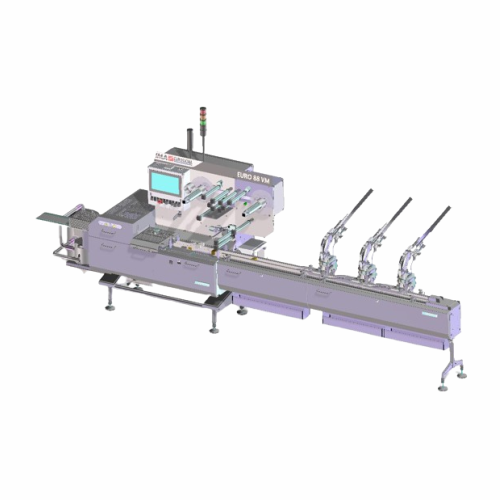

The EURO 88 VM from IMA Group is a versatile flow wrapper designed specifically for efficiently portioning and wrapping dry and flat biscuits in neat stacks. Equipped with gravity feeders and vertical loaders, this machine ensures precise and consistent feeding onto the wrapper’s chain, making it an ideal solution for semi-automated packaging lines in the food and bakery industries. It accommodates diverse product sizes, from digestive biscuits to square crackers, by facilitating easy customization and seamless integration into existing operations. Its modular design allows for the addition of self-cleaning vibrating channels, enhancing cleanliness and reducing downtime associated with maintenance. Additionally, the EURO 88 VM optimizes packaging efficiency with its ability to handle a wide range of film reel dimensions, accommodating varying production requirements.

Benefits

- Enhances packaging efficiency with precise portioning for consistent product presentation.

- Reduces maintenance time with customizable self-cleaning vibrating channels.

- Seamlessly integrates into semi-automated lines, boosting operational productivity.

- Accommodates various biscuit types, providing flexibility in production.

- Adjusts to different film dimensions, enabling adaptability to diverse packaging needs.

- Applications

- Bakery products, Biscuits, Snacks

- End products

- Wafer biscuits, Plain cookies, Digestive biscuits, Shortbread, Tea biscuits, Square crackers, Marie biscuits, Cream cracker, Graham crackers, Oat biscuits

- Steps before

- Biscuit Production, Biscuit Baking

- Steps after

- Packaging, Case Packing, Palletizing

- Input ingredients

- dry biscuits, plain biscuits

- Output ingredients

- stacked biscuits

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Product Size Range (Length)

- 35 to 950 mm

- Product Size Range (Width)

- 35 to 560 mm

- Product Size Range (Thickness)

- 5 to 60 mm

- Film Reel Inner Diameter

- 70 to 79 mm

- Film Reel External Diameter

- Up to 380 mm

- Film Reel Width

- 350/500 (opt)/ 650 (box motion) mm

- Max Film Reel Weight

- 25 kg

- Construction Type

- Modular

- Application Type

- Semi-automated lines

- Feeder Type

- Gravity Feeders

- Working mechanism

- Flow wrapping with gravity feeders

- Integrated steps

- Stacking and wrapping

- Feeding system

- Gravity loaders

- Operation type

- Semi-automated

- Changeover time

- Modular construction for varied needs

- Cleaning method

- Self-cleaning vibrating channels

- Automation level

- Possibility to link with self-cleaning systems

- Batch vs. continuous operation

- Semi-automated lines

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Vertical feeder type

- Gravity loaders

- Product discharge method

- Running chain of the wrapper

- Film reel dimensions

- Inner diameter

- Modular construction

- Yes

- Integration with semi-automated lines

- Yes

- Self-cleaning vibrating channels

- Linkable to vertical loaders