Wafer sheet cooling system

Ensure optimal cooling and conditioning of baked wafer sheets with a system designed to maintain integrity and quality, accommodating seamless integration into high-speed, continuous production lines.

Cools and Conditions Wafer Sheets

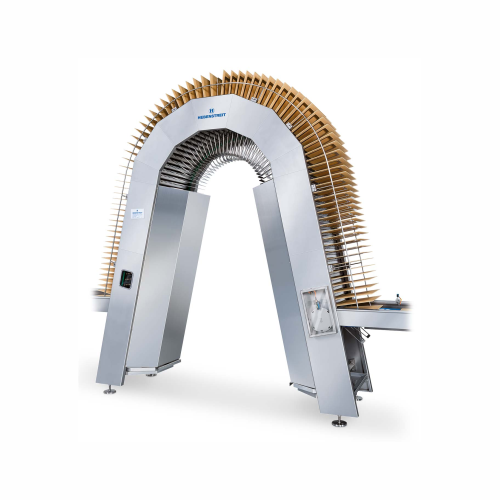

The Wafer Sheet Cooler EPH from Hebenstreit GmbH is engineered to provide efficient cooling and conditioning of wafer sheets in high-speed, continuous operations. Designed for snack manufacturers, wafer producers, and food processing companies, it stands out for its arch-shaped configuration, allowing personnel easy access and mobility underneath. This cooler effectively reduces thermal stress, preserving the structural integrity of flat and coated wafers before they move to subsequent processes like spreading, stacking, and sandwich cooling.

With applications spanning snacks, extruded products, and cereals, the EPH model is versatile, handling various end-products such as flat wafers, hollow wafers, and even pork rind snacks. The equipment operates seamlessly within existing production lines, integrating an energy-efficient cooling process that optimizes air flow for uniform temperature control.

Capable of processing large volumes with minimal energy consumption, its construction materials ensure durability and compliance with industry standards. Hebenstreit offers customization options to align with specific production requirements, with comprehensive engineering support for configuration and integration. Additionally, the cooler’s robust design facilitates easy cleaning and maintenance, ensuring continuous operation with minimal downtime.

Benefits

- Enhances product quality by reducing thermal stress on wafer sheets.

- Facilitates efficient production flow with its unique arch design for unobstructed access.

- Integrates seamlessly into existing lines with energy-efficient cooling operations.

- Supports a wide range of products, increasing production line versatility.

- Minimizes maintenance needs with easy access for cleaning and service.

- Applications

- Wafers, Snacks, Pet food, Cereals, Extruded products

- End products

- Moulded wafers, Pork rind snacks, Flakes, Spirals, Curls, Coated hollow wafers, Rings, Protein crisps, Flat wafers, Microcrispies, Hollow wafers, Breakfast cereals, Filled snacks, Malt rings, Flat breads, Whole grain curls, Legumes snacks, Crispies, Croûtons, Coated wafers, Balls, Sticks

- Steps before

- Batter Preparation, Baking

- Steps after

- Spreading, Stacking, Sandwich Cooling, Cutting, Discharge, Distribution

- Input ingredients

- baked wafer sheets, wafer batter

- Output ingredients

- cooled wafer sheets

- Market info

- Hebenstreit is known for specializing in the manufacture of industrial equipment for wafer production, offering advanced technology and customization for the food industry, with a reputation for high-quality and reliable machinery.

- Cooling Time

- 2-3 minutes

- Structure

- Arch form

- Design Flexibility

- Designed to suit plant capacity and current requirements

- Wafer Type Compatibility

- Baked wafer sheets

- Cooling time

- 2–3 minutes

- Working mechanism

- Arched cooling system

- Flow type

- Inline

- Capacity adaptability

- Designed to suit plant capacity

- Integration in production line

- Allows personnel movement

- Machine footprint

- Customizable to suit plant capacity

- Cooling path design

- Arch-shaped design for stress-free cooling

- Headroom

- Designed to allow walking underneath

- Width

- Customizable to current requirements

- Feed/discharge method

- Wafer sheets transported through cooler

- Headroom

- Customized to suit plant capacity

- Width

- Customized to suit plant capacity

- Construction type

- Arch form