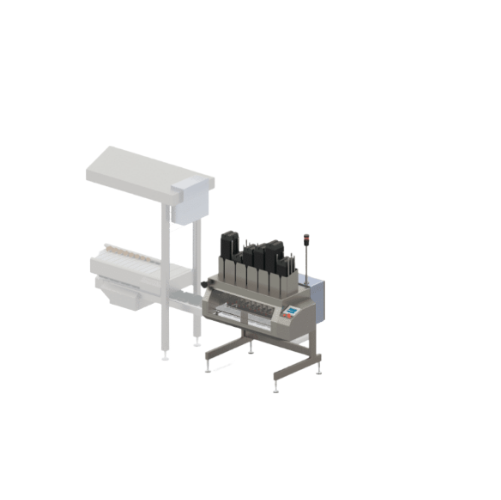

Automatic tray denesting and erecting system

Streamline your packaging line with precise and efficient tray handling—ensuring consistent tray separation and erection for seamless flow in high-speed food production environments.

Denests and Erects Packaging Trays

The Plastic Tray Denester and Carton Tray Erector by Royal Houdijk is a high-speed solution designed for seamless integration into food packaging lines. Engineered for automatic and continuous operation, it excels in precisely denesting and erecting trays for various applications, including bakery goods, frozen foods, and ready meals. Capable of handling multiple tray types, from plastic to carton, this system enhances throughput and reduces manual handling times.

Key features include a robust PLC-controlled interface, facilitating easy integration into existing production systems with remote monitoring capabilities for streamlined operations. The system’s efficient motor control reduces energy consumption, offering both economic and environmental advantages. Constructed from durable materials to ensure longevity and resistance to wear, it meets stringent industry standards, ensuring compliance in packaging environments.

For industries looking for tailored solutions, the equipment offers customization options to accommodate specific production needs. With a focus on minimizing downtime, the system incorporates user-friendly maintenance protocols and supports quick tray size and format adjustments. Whether in high-demand bakery lines or diverse ready-meal packaging, this denester and erector offer unparalleled versatility and efficiency.

Benefits

- Enhances packaging efficiency by automating tray denesting and erecting processes.

- Minimizes manual labor costs through continuous, high-speed operation.

- Reduces energy use with optimized motor control systems.

- Supports diverse product lines with flexible tray size adjustments.

- Ensures compliance with industry standards for food packaging environments.

- Applications

- Food packaging, Plastic packaging, Tray handling, Carton packaging

- End products

- Ready meal containers, Meat and poultry trays, Beverage carton carriers, Snack food packaging, Frozen food packaging trays, Seafood packaging containers, Dairy product trays, Fresh produce cradles, Confectionery trays, Bakery trays

- Steps before

- Tray Production, Material Loading

- Steps after

- Product Filling, Sealing, Packaging

- Input ingredients

- plastic trays, carton trays

- Output ingredients

- denested trays, erected trays

- Market info

- Houdijk is known for designing and manufacturing advanced handling and processing equipment for the biscuit and bakery industry, specializing in automated systems to improve efficiency and maintain product quality.

- Tray Handling

- Automatic Plastic Tray Denesting and Carton Tray Erecting

- Automation

- Automatic

- Automation level

- Automatic

- Changeover time

- Quick

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual / CIP

- Plastic Compatibility

- Yes

- Carton Compatibility

- Yes

- Tray type

- Plastic / Carton

- Feed Method

- Automatic