Camera quality control for industrial production

Ensure flawless product quality by integrating a precision optical inspection system capable of multi-channel analysis and accurate rejection, minimizing waste and maximizing efficiency in high-speed production lines.

Inspects and Rejects Defective Products

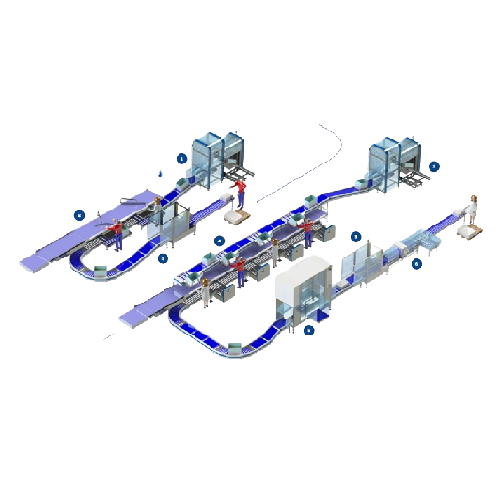

The Quality Checker from Niverplast is a versatile camera system designed for comprehensive product inspection in the bakery, food production, and packaging sectors. It employs a multi-channel camera setup capable of evaluating multiple product types simultaneously, such as baguettes and bakery rolls, by assessing dimensions and surface characteristics. The system features an intuitive touchscreen interface for easy operation and can adapt to any production speed, ensuring seamless integration into your existing production line. With a compact design executed in stainless steel, the Quality Checker is both durable and easy to maintain. Equipped with servo-driven retract conveyors, it ensures precise rejection of non-compliant products, minimizing waste. Its capability to store and analyze inspection data helps in refining quality control processes over time. Customization options, such as the number of reject belts and SQL software tools, are available to fit specific production requirements.

Benefits

- Enhances product quality by accurately identifying and rejecting defective items.

- Integrates seamlessly into production lines with variable speed compatibility.

- Reduces operational costs through minimized waste and optimized resources.

- Offers easy maintenance with a compact, stainless steel design.

- Supports diverse production needs with customizable rejection and inspection options.

- Applications

- E-commerce, Bakery, Meat, Fats, Oils, Fruits, Laundry, Powder, Vegetables, Moulding, Fish

- End products

- Baguettes, Kaiser rolls, Under-baked bread, Over-baked bread, Bakery rolls, Black-spotted products

- Steps before

- Product sorting, Initial inspection, Calibration of quality standards

- Steps after

- Product packing, Labeling, Storage or shipping

- Input ingredients

- baguettes, Kaiser rolls, products

- Output ingredients

- approved products, rejected products

- Market info

- Niverplast is known for innovative packaging solutions, specializing in industrial engineered-to-order equipment for bag-in-box systems, tray handling, and carton erecting machinery, with a strong reputation for quality and reliability in the packaging industry.

- Channels

- Up to 6 channels

- Capacity

- Depends on amount of quality requirements to check

- Rejection System

- Up to 8 retractable belts

- Dimension Accuracy

- Accuracy 2 mm

- Production Speed

- Capable to match any production speed

- Material

- Stainless steel

- Control Interface

- Touchscreen with interactive software

- Optional Features

- 6 or 8 reject belts, SQL software tool

- Automation

- Niverplast software integration

- Multi-product channels

- Up to six channels

- Product rejection mechanism

- Retractable belts

- Automation level

- Easy adjustment and operation

- Modular configuration

- Optional 6 or 8 reject belts

- Data management

- Data saving per product

- Integration with reject module

- Niverplast software

- Material construction

- Stainless steel

- Interactive control

- Touchscreen with interactive software

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CE marking

- Yes

- FDA compliance

- Possible

- FDA materials

- Stainless steel

- Machine footprint

- Compact design with a small floor print

- Material of construction

- Stainless steel

- Control panel type

- Touchscreen with interactive software

- Discharge method

- Servo-driven retractable conveyor

- Compact footprint

- Small floor print, compact design

- Control panel type

- Touchscreen with interactive software

- Integration capabilities

- System coupled with reject module by Niverplast software, optional SQL software tool

- Channel configuration

- Up to six independent channels

- Product rejection configuration

- Optional 6 or 8 retract belts