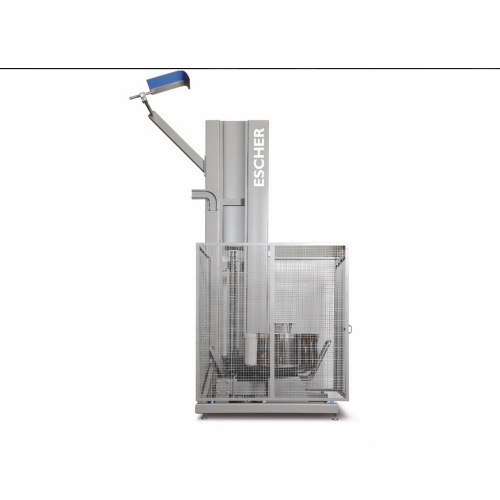

Industrial bowl lifter-tipper

Streamline your bakery production with a solution that simplifies dough handling by seamlessly lifting, tipping, and rotating, enhancing efficiency and ensuring consistent mixing quality across various dough types.

Lifts, Tips, and Rotates Dough Bowls

The ESBL Sollevatori from Escher Mixers is a versatile bowl lifter-tipper designed specifically for the food and bakery industries. This robust equipment effectively tackles the challenge of handling large batches of dough by providing seamless integration into existing production lines. It features both semi-automatic and fully automatic lifting and tipping capabilities, facilitating efficient upstream processing. With a bowl rotation system utilizing either a friction wheel or Escher’s patented technology, along with an optional bowl scraper, it ensures consistent processing of doughs for a range of baked goods such as bread loaves, pastries, and cookies. Its design supports heights of up to 3.5 meters, offering intermediate options for various operational needs. The ESBL Sollevatori can be configured with interface systems for feeding hoppers and subsequent systems, optimizing a wide array of food manufacturing processes. Built with food-grade materials, it assures compliance with hygienic standards while minimizing maintenance efforts.

Benefits

- Enhances productivity by seamlessly integrating lifting and tipping into existing baking processes.

- Minimizes manual intervention, reducing labor costs and operational risks.

- Customizable height options optimize space utilization in diverse production layouts.

- Supports hygienic operations with food-grade materials and compliance with industry standards.

- Reduces energy usage through efficient motor control and patented bowl rotation technology.

- Applications

- Bakery automation systems, Industrial bakery products, Dough processing, Food manufacturing, Ingredient mixing, Artisan bakery products

- End products

- Doughnuts, Cookies, Baguettes, Pizza dough, Artisan sourdough, Buns, Biscuit dough, Breadsticks, Muffin batter, Bread loaves, Bagel dough, Croissants, Pie crusts, Pastries, Cake batter, Industrial ciabatta, Pretzels

- Steps before

- Feeding, Loading

- Steps after

- Dividing, Interfacing with feeding hoppers, Output handling, Lowering, Safety operations

- Input ingredients

- bowl, ingredients for mixing, industrial applications

- Output ingredients

- output on table, output on standard divider, output up to 3.5 m height

- Market info

- Escher Mixers (Middleby) is known for manufacturing high-quality, engineered-to-order mixing equipment, specializing in spiral and planetary mixers, primarily for the bakery industry. They are reputed for innovative solutions and reliability in industrial dough mixing.

- Bowl rotation system

- Friction wheel/Escher patented system

- Bowl output height

- Up to 3.5 meters

- Bowl scraper

- Optional

- Safety grid

- Included

- Lifting mechanism

- Semi or fully automatic

- Interface systems

- Feeding hoppers integration

- Lifting mechanism

- Friction wheel / Patented system

- Automation level

- Semi / Fully automatic

- Output height range

- Table level to 3.5 m

- Interface system

- Feeding hoppers

- Safety features

- Safety grid

- Rotation system

- Friction wheel / Patented system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Bowl size range

- Standard to industrial sizes

- Discharge method

- Table output / Standard divider output / Up to 3.5 m height output

- Interface systems

- With feeding hoppers and systems afterwards

- Height

- Up to 3.5 m

- Adjustment options

- Semi or fully automatic lifting/output/lowering

- Bowl rotation system

- Friction wheel / Escher patented system

- Lifting mechanism

- Semi or fully automatic

- Interface systems

- Feeding hoppers and systems