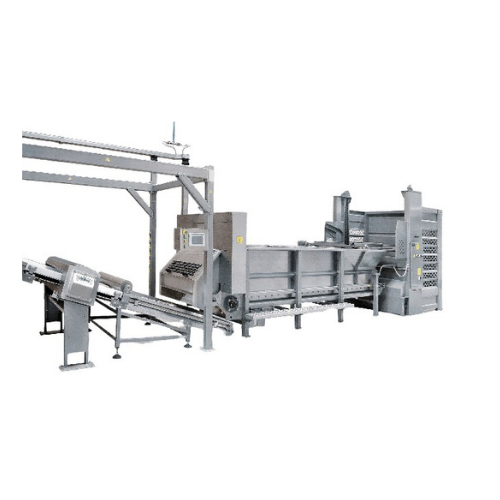

Dough feeding system for biscuits and cookies

Streamline your bakery production with a dough feeding system that efficiently handles diverse dough textures, ensuring consistent and precise portioning for your biscuits, cookies, and crackers.

Feeds, Lifts, Portions, and Monitors Dough

GEA’s Dough Feeding System is designed to seamlessly integrate into bakery production lines, enhancing efficiency in the processing of soft dough cookies, hard sweet biscuits, and rotary molded biscuits. This system features a vertical tub elevator for lifting and tilting dough into hoppers, and advanced monitoring sensors that adjust the dough flow to match production demands. It offers configurations including overhead hoppers with pneumatic guillotines and pocket rollers for precise portioning. Optional metal detectors ensure safety, while dough crumblers maintain processing efficiency by breaking up lumps. Available compliance with stringent food safety standards and constructed from high-quality food-grade materials, GEA’s system promotes hygiene and reduces energy consumption through optimized motor controls. With easy access for cleaning and maintenance, this equipment supports continuous high-speed operation and can be customized to fit specific plant layouts and product textures.

Benefits

- Enhances production efficiency with seamless integration into automated lines.

- Ensures product safety with integrated metal detectors on exit conveyors.

- Maintains consistent product quality through precise portioning and monitoring.

- Reduces energy use with optimized motor control technologies.

- Facilitates quick cleaning with easy-access design and food-grade materials.

- Applications

- Hard sweet biscuits, Cookies, Biscuits, Soft dough cookies, Rotary molded biscuits, Crackers

- End products

- Rich tea biscuits, Digestive biscuits, Animal crackers, Chocolate chip cookies, Mary biscuits, Peanut butter cookies, Saltine crackers, Ginger snaps, Shortbread cookies, Vanilla wafers, Chewy oatmeal cookies, Almond crackers

- Steps before

- Dough Mixing, Dough Crumbling

- Steps after

- Conveying to Forming Machines, Forming, Baking, Cooling, Packing

- Input ingredients

- soft dough cookies, hard biscuits, cracker dough, sweet biscuit dough

- Output ingredients

- dough portions, processed soft cookies, hard biscuits, crackers

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- Varies based on system configuration

- Dough Texture Compatibility

- Soft, hard, and variable viscosity doughs

- Integration Capability

- End-to-end line integration

- Automation

- Pneumatic control with guillotine

- Metal Detection

- Equipped on exit conveyor

- Dough Portioning

- Pocket rollers or guillotine

- Cleaning Access

- Easy access for cleaning

- Construction Material

- High-quality food grade materials

- Dough Crumbling

- Integrated crumbler for rotary molding

- Hopper System

- Overhead hopper

- Tub Lifting

- Vertical tub elevator

- Monitoring System

- Sensors for dough level monitoring

- Forming Control

- Speed control of conveyors

- Working mechanism

- Hopper and pneumatic guillotine

- Integrated steps

- Tub-lifting, dough portioning, metal detection

- Dough handling capability

- Soft dough cookies, hard biscuits, crackers

- Batch vs. continuous operation

- Continuous inline

- Changeover time

- Minimized through modular design

- Cleaning method

- Easy access for manual cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tub shape and size

- Vertical tub

- Discharge method

- Overhead hopper with pneumatic guillotine

- System configuration

- Ground-level tub-lifting and tilting, overhead hopper, pneumatic guillotine

- Integration possibilities

- Integration with existing production lines

- Control system

- Sensors for dough level monitoring, speed control of feeding conveyors

- Hygiene design

- Food safety and hygiene compliant materials

- Cleaning access

- Easy access for cleaning

- Dough types

- Soft cookies, hard biscuits, crackers

- Dough portioning

- Pocket rollers for dough portions

- Metal detection

- Metal detectors on exit conveyors

- Dough crumbling

- Dough crumbling technology to break lumps

- Tub elevator

- Vertical tub elevator for lifting and tilting