Bakery product quality control and counting system

Optimize your bakery line with precise control and counting of long products, ensuring seamless batch creation while rejecting non-compliant items—all within a compact system designed to handle high-speed operations.

Controls Quality, Counts, and Creates Batches

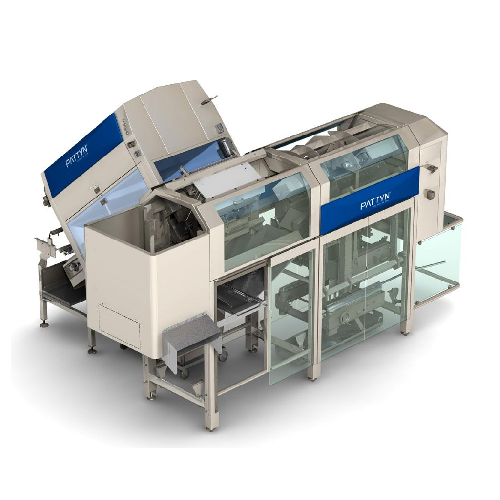

The Quality Control, Product Counter & Batch Creator CQC developed by Pattyn Bakery Division is a compact solution designed for industrial bakeries and food processing companies. Utilizing advanced 3D vision technology, it precisely inspects and rejects defective baguettes and barras, ensuring only compliant products reach final batch creation. With versions available for both prebaked and raw products, the CQC caters to a wide range of bakery applications, including French baguettes and artisan breads. Capable of processing up to 12,000 baguettes or 40,000 subway sticks per hour, the CQC optimizes throughput while occupying minimal floor space. Fully integratable into automated packaging lines, it pairs seamlessly with Pattyn’s case erectors and sealers, facilitating a complete automated bulk packaging process. Designed with efficiency in mind, this system combines quality assurance, counting, and packaging in one streamlined unit, reducing operational complexity and boosting productivity.

Benefits

- Ensures precise product quality with 3D vision inspection and automatic defect rejection.

- Increases production efficiency by handling up to 12,000 baguettes per hour.

- Saves floor space with its compact design integrating quality control, counting, and batch creation.

- Enhances operational flexibility with versions for both prebaked and raw products.

- Facilitates full automation in packaging lines when combined with Pattyn's ancillary equipment.

- Applications

- Raw products, Baguettes, Prebaked products, Subway sticks, Barras, Bakery products

- End products

- Raw baguette dough, Whole wheat baguettes, Subway white bread, Sourdough baguettes, Classic barras loaves, French baguettes, Subway multigrain bread, Whole grain barras, Raw artisan dough, Prebaked artisan breads, Prebaked wholemeal rolls

- Steps before

- Production Line Setup, Product Preparation, Prebaking (if applicable)

- Steps after

- Packing, Case Erecting, Bag Inserting, Bag Sealing, Case Closing

- Input ingredients

- long bakery products, baguettes, barras, subway sticks, prebaked products, raw products

- Output ingredients

- controlled bakery products, counted products, batch created products, rejected non-compliant products

- Market info

- Pattyn is known for its expertise in designing and manufacturing industrial packaging solutions, specializing in ETO equipment for bulk packaging automation, with a strong reputation for innovation, quality, and customer-focused service in the industry.

- Capacity

- Up to 12, 000 baguettes/hour or 40, 000 Subway sticks/hour

- Batch size

- Up to 20 batches/min

- Automation

- Fully automated

- Detection type

- 3D vision system

- Accuracy

- Length, width, and height checks

- Compact footprint

- Low space occupation

- Automation level

- Fully automated

- Batch vs. continuous operation

- Batch

- Changeover time

- Minimal

- Cleaning method

- Manual

- Energy efficiency

- Optimal for bakery operations

- Integrated functions

- Quality control, counting, batch creation

- Space efficiency

- Compact design

- Machine Footprint

- Compact

- Integration

- 3-in-1 Functionality

- Discharge Method

- Batch Creation and Product Counting