Stunner monitoring and reporting system for poultry processing

Optimize your stunner performance by accessing real-time and historical data that helps ensure consistent quality and compliance with animal welfare audits.

Monitors and Reports Stunner Performance

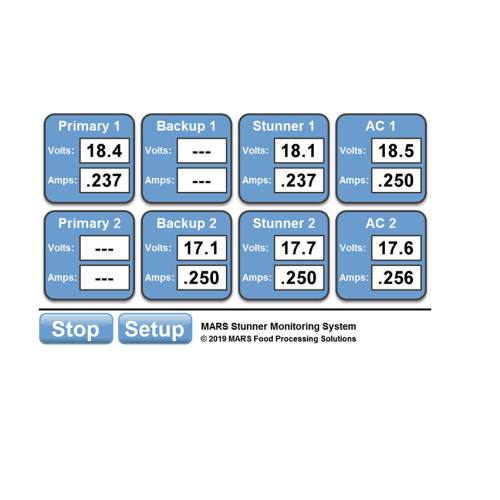

The JBT MARS Stunner Monitoring and Reporting System is designed for poultry and meat processing plants requiring precise equipment performance analysis. Its real-time monitoring captures vital data on voltage and amperage, allowing you to optimize stunner settings for different poultry breeds and sizes, ultimately improving meat quality and animal welfare compliance. Operating continuously, it seamlessly integrates into automated processing lines, enabling you to monitor up to two stunners via a user-friendly 7-inch touchscreen interface. Data is securely stored in a Microsoft SQL Server database, accessible for reports and audits. This system supports informed decision-making, reducing the risk of production issues such as meat downgrades and improper stunning without localized data storage concerns. Configured for diverse processing environments, it facilitates efficient operational oversight and long-term data analysis.

Benefits

- Enhances meat quality by optimizing stunner settings per poultry breed and size.

- Facilitates animal welfare compliance through accurate data for audits.

- Reduces downtime with continuous real-time monitoring and automated data storage.

- Provides easy access to performance insights via a user-friendly touchscreen interface.

- Integrates seamlessly with existing automated processing lines to streamline operations.

- Applications

- Seafood, Ready meals, Pet food, Meat, Poultry

- End products

- Turkey wings, Chicken nuggets, Chicken breasts, Pre-cooked chicken strips, Duck legs, Fully cooked ready chicken meals, Seafood fillets, Pet food poultry chunks, Whole broiler chickens, Processed poultry sausages, Battered chicken wings, Deli sliced turkey

- Steps before

- Poultry Processing - Primary, Injection, Marination, Portioning, Slicing

- Steps after

- Poultry Processing - Secondary, Freezing, Chilling, Proofing, Coating, Cooking

- Input ingredients

- poultry, birds, poultry breeds, flocks

- Output ingredients

- stunned poultry, meat without downgrades, ethical stunning, quality wing joints

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Data Update Interval

- 5 seconds

- Display Type

- 7-inch touchscreen

- Data Storage

- Microsoft SQL Server

- Monitoring Capability

- Amperage and Voltage

- Stunner Compatibility

- Up to two stunners

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Live data update interval

- 5 seconds

- Data storage and accessibility

- Stored on Microsoft SQL Server

- User Interface

- 7-inch touchscreen display

- Number of stunners managed

- Up to two

- Control panel type

- Touchscreen

- Compact footprint

- Yes

- Control panel type

- 7-inch touchscreen

- Data storage method

- Microsoft SQL Server

- Integration possibilities

- Report emailing, alarms

- User interface

- User-friendly interface