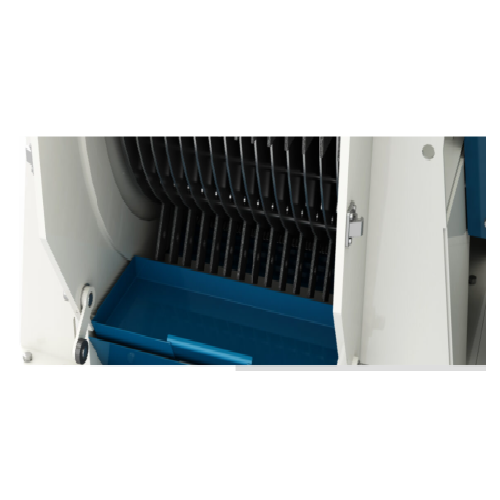

Quick hammer exchange system for hammer mills

Streamline hammer replacement in your milling process with a system designed to reduce manpower and downtime—perfect for operations requiring frequent maintenance for optimal feed quality.

Facilitates Quick Hammer Replacement in Mills

Ottevanger’s Quick Hammer Exchange System revolutionizes maintenance in hammer mills, reducing labor requirements from two operators to one. It boosts efficiency by enabling swift hammer replacement, critical for maintaining feed quality across applications in feed, animal feed, pet food, and grain processing. The system operates through a user-friendly mechanism that simplifies access to hammers, minimizing operational downtime. This engineered solution integrates seamlessly within existing milling and grinding processes and is suitable for manual and semi-automatic operations. Designed for durability and efficiency, it supports the production of pelletized animal feed, poultry feed mash, and other granule or powder products, ensuring consistent output with less maintenance interruption.

Benefits

- Reduces labor costs by allowing single-person hammer replacement.

- Minimizes production downtime, enhancing overall process efficiency.

- Increases ease of maintenance with straightforward access to components.

- Ensures continuous high feed quality with timely hammer changes.

- Streamlines operations in diverse feed and grain processing environments.

- Applications

- Animal feed, Feed, Pet food, Grain processing, Aqua feed, Concentrates, Premix

- End products

- Vitamin concentrate mix, Fish pellets, Cat kibble, Mineral premixes, Crushed grain meal, Pelletized animal feed, Poultry feed mash

- Steps before

- Grinding, Pre-cleaning, Micro Dosing

- Steps after

- Sieving, Pelleting, Crumbling

- Input ingredients

- feed raw material

- Output ingredients

- processed feed, quality feed

- Market info

- Ottevanger Milling Engineers is renowned for designing and manufacturing innovative milling equipment and complete production lines for the grain processing industry, including feed mills, flour mills, and biomass processing, with a reputation for quality, efficiency, and customized solutions.

- Automation

- Single-person operation

- Time for hammer replacement

- Reduced time

- User-friendly access

- Easy hammer accessibility

- System compatibility

- Hammer Mills GHM

- Labor requirement

- Single-person

- Down time

- Less down time

- Changeover time

- Reduced with QHE System

- Automation level

- Manual / Single Operator

- Batch vs. continuous operation

- N/A

- Energy efficiency

- Minimized downtime

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Quick hammer exchange

- Access method

- Easy access for single-person operation

- Control panel type

- Manual / Automated

- Integration possibilities

- Compatible with existing hammer mills

- User interface accessibility

- Single-person operation