Low-emission belt dryer for timber industry

Achieve maximum drying efficiency and significant energy savings in your processing line with an advanced belt dryer that integrates energy recovery through a dual-module design, ensuring optimal air circulation and reduced emissions.

Reduces Moisture and Recovers Heat Efficiently

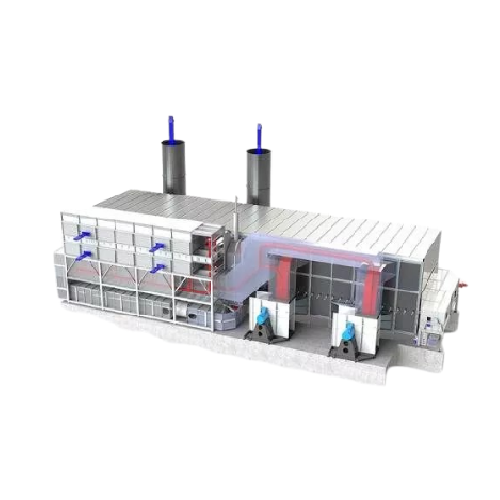

The Belt Dryer BTU RecuDry® from STELA Laxhuber sets a new standard in industrial drying by effectively reducing energy consumption and emissions. This equipment features a dual-zone drying process, leveraging both the Recu and condensation modules to utilize energy-rich air and maximize heat recovery. Ideal for drying a range of solid, powder, and granule forms, it supports industries including agriculture, timber, food processing, pet food, pulp and paper, pellet production, cement manufacturing, renewable fuels, recycling, and water management. Capable of processing up to 14.8 tons per hour, it ensures continuous, low-temperature, and efficient moisture reduction, making it perfect for diverse applications such as drying grains, wood chips, pet food, and sewage sludge pellets. Integrated with a PLC-controlled system, it allows seamless adaptation into existing production lines and offers energy savings between 35% to 55%. Constructed for durability, the dryer is engineered to retrofit existing systems with ease, enhancing efficiency and operational performance without compromising on material integrity or compliance standards.

Benefits

- Cuts energy usage by up to 55% through efficient heat recovery.

- Lowers operational emissions, supporting sustainable production practices.

- Enhances process integration with easy retrofitting to existing systems.

- Provides continuous low-temperature drying, protecting product quality.

- Adapts to various industrial applications, boosting versatility and production line flexibility.

- Applications

- Water management, Timber, Pet food, Pellets, Recycling materials, Renewable fuels, Agricultural products, Foodstuffs, Pulp and paper, Cement

- End products

- Osb chipboards, Wood chips, High-quality pet food, Recycled paper products, Dried vegetables, Snack extrudates, Dried grains, Sewage sludge pellets, Cement kiln fuels, Alternative fuel pellets

- Steps before

- Chipping, Grinding, Moisture Measurement, Material Sorting

- Steps after

- Packing, Pelletizing, Bulk Storage, Transportation

- Input ingredients

- sawdust 50%, wood chips 50%, sawdust 57%, SRF 20%

- Output ingredients

- sawdust 10%, sawdust 6%, sawdust 11%, wood chips 25%, sawdust 9%, SRF 10%

- Market info

- Stela Laxhuber is known for their expertise in manufacturing custom-engineered drying systems, particularly belt dryers for biomass, sludge, and food industries, with a reputation for innovation, quality, and energy efficiency in the market.

- Dryer output capacity

- sawdust

- Energy saving

- 35 – 55%, depending on drying surface area

- Drying efficiency

- Maximum

- Use of energy recovery via air-to-air heat exchanger

- Exhaust airflows and emissions

- Low

- System convertibility

- Existing systems can be converted to RecuDry®

- Dryer type

- Belt dryer / Layer dryer

- Heat recovery

- Air-to-air heat exchanger

- Moisture reduction

- Sawdust from 50% to 10% / SRF from 20% to 10%

- Primary drying substance

- Sawdust / Wood chips / SRF

- Heat source

- Convection via recirculation and reheating

- Working mechanism

- Belt dryer with recirculation and reheating

- Energy recovery method

- Air-to-air heat exchanger

- Circulation type

- Uses energy-rich air in condensation module

- Drying efficiency

- 35 – 55% energy savings

- Automation level

- PLC

- Emissions control

- Low exhaust airflows

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Feed material type

- Sawdust, SRF, Wood chips

- Machine footprint

- Varies per model

- Feed/discharge method

- Conveyor belt

- Belt width

- 1.6200 - 3.000 m

- Modular system

- Yes

- Compact footprint

- Designed for space optimization

- Control panel type

- PLC-controlled

- Control panel type

- PLC-controlled

- Integration possibilities

- Compatible with existing systems

- Energy recovery module

- Air-to-air heat exchanger