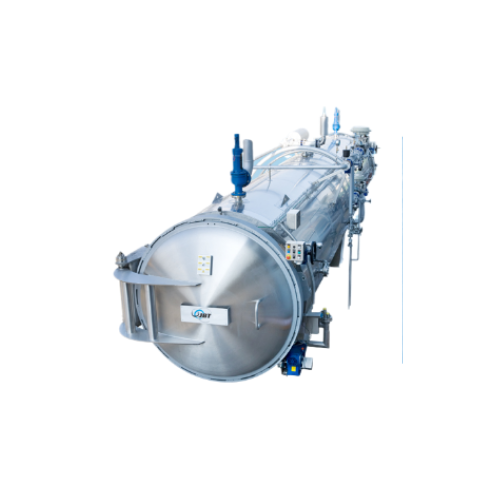

Tuna vacuum pre-cooker cooler

Optimize your tuna and seafood processing with precise thawing, cooking, and cooling under vacuum conditions, enhancing product yield and quality while minimizing oxidation for superior end results.

Thaws, Cooks, and Cools Tuna Efficiently

The Tuna Vacuum Pre-Cooker Cooler from JBT FoodTech is engineered to optimize seafood processing by thawing, cooking, and cooling under controlled vacuum-pressure conditions. This equipment is particularly valuable for processing tuna fillets, canned seafood, and wet pet food products. The use of TunaCAL™ mathematical modeling software ensures precise temperature control and heat distribution, enhancing yield and product quality while minimizing oxidation. With a capacity of up to eight tons per cycle, this system features automatic loading and unloading via a “drag chain” mechanical system for seamless integration into existing production lines. The inclusion of options such as a steam ejector vacuum system further enhances its effectiveness. Built with durable materials, it supports CIP systems for easy maintenance, making it a reliable and efficient choice for food and pet food processing companies.

Benefits

- Enhances product quality with uniform heat distribution and reduced oxidation.

- Increases yield by efficiently managing thawing and cooking cycles.

- Streamlines operations with automatic loading and unloading systems.

- Optimizes production consistency using predictive modeling software.

- Facilitates easy maintenance with built-in CIP system compatibility.

- Applications

- Seafood, Pet food, Meat, Tuna processing, Poultry

- End products

- Tuna fillets, Canned pet food, Wet pet food, Chicken breast, Shrimp, Tuna chunks, Processed meat products, Canned tuna, Tuna loins, Vacuum-packed seafood, Cooked poultry, Cooked meat strips

- Steps before

- Thawing, Preparation, Loading

- Steps after

- Cooling, Filling, Packaging

- Input ingredients

- tuna fish, shellfish, cephalopod, raw fish

- Output ingredients

- cooked tuna, cooked shellfish, cooked cephalopod, cooking broths

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Capacity

- Up to 8 tons/cycle

- Automation

- Automatic loading and unloading through "drag chain" system

- Heat Distribution

- Uniform inside the chamber

- Yield and Product Quality

- Increased yield, high product quality

- Vacuum System

- Steam ejector vacuum

- Mathematical Modeling Software

- TunaCAL™

- Cooling Method

- Steam ejector vacuum cooling

- Working Mechanism

- Steam vacuum-pressure

- Integrated Steps

- Cooking and Cooling

- Automation Level

- Automatic loading/unloading

- Batch vs. continuous operation

- Batch

- Yield Optimization

- Increased yield

- Machine footprint

- Depends on model and configuration

- Chamber size

- Holds up to eight tons of product

- Loading method

- Automatic "drag chain" mechanical system

- Discharge method

- Automatic unloading