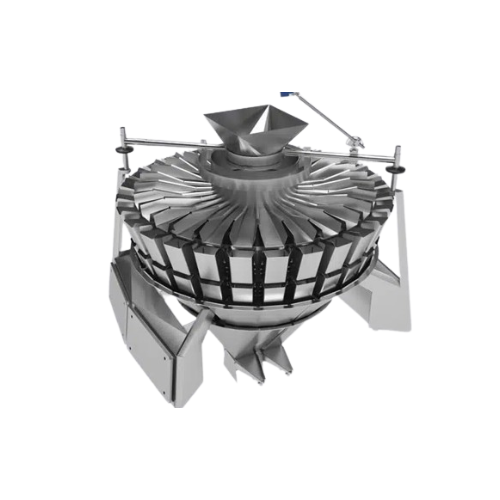

Multihead weigher with vibratory feeding

Experience precise and efficient weighing with a multihead system designed for complex products, enhancing speed and precision in your production line operations.

Precisely Weighs and Feeds Solid Products

The Multihead Weigher with Vibratory Feeding (MHW VF) from Cabinplant is designed to streamline precision weighing in food processing. Utilizing vibratory feeding, the system provides accurate portioning by controlling product flow through time and amplitude adjustments. Ideal for products like fish fillets, cheese cubes, and ready-to-eat meals, this equipment supports various applications in industries such as seafood, meat, and convenience food.

Capable of handling continuous high-speed operations, the MHW VF ensures minimal giveaway and consistent accuracy across diverse product types, including solid and granular forms. The equipment can be configured with multiple heads and customizable pan sizes, improving throughput and efficiency tailored to specific production needs.

Its robust construction is tailored for low maintenance, with easy-to-clean surfaces reducing downtime. The PLC control system enables seamless integration into existing production lines, enhancing automation and precision. Energy consumption is minimized through optimized vibration motor controls, and the system’s flexible design accommodates a range of material contact surfaces, making it suitable for handling sticky or frozen products. Available customer-centric solutions ensure that your requirements are met with dedicated engineering support.

Benefits

- Enhances production efficiency with precise portion weighing and reduced product giveaway.

- Decreases maintenance needs and operational interruptions due to easy-to-clean design.

- Supports high-speed operations, ensuring consistent output for demanding processing environments.

- Adapts to various product types, including sticky and frozen, with customizable material surfaces.

- Seamlessly integrates with existing lines, offering flexible configurations for specific production requirements.

- Applications

- Seafood, Dairy food, Berries, Convenience food, Pet food, Meat, Fruits, Vegetables, Poultry, Fish

- End products

- Chicken nuggets, Cheese cubes, Carrot sticks, Apple slices, Pet kibble, Shrimp, Sliced turkey, Frozen berries, Ready-to-eat meals, Fish fillets, Cut vegetables

- Steps before

- Sorting, Thawing, Glazing, Preparation

- Steps after

- Packing, Filling, Dosing

- Input ingredients

- dry products, frozen products, sticky products, complex products, fish, seafood, meat, poultry, fruits, vegetables, dairy food, convenience food, pet food

- Output ingredients

- weighed portions, packaged products, bags, buckets, cans, glass jars, cups, trays

- Market info

- Cabinplant is known for designing and manufacturing tailored processing solutions for the food industry, specializing in fish, seafood, fruits, and vegetables. They are reputed for their innovative technology and efficiency in delivering customer-specific engineered-to-order equipment.

- Type of Weighing

- Single or multiple weighing, Flow weighing, Floating set-point weighing, Multiple target weighing, Mix weighing

- Pan size

- Various configurations available such as 10–28

- Number of Heads

- Available in configurations such as 10, 12, 14, 18, 20, 24, 28

- Vibratory Feeding

- Yes

- Weighing Accuracy

- Excellent

- Noise Level

- Minimum

- Maintenance

- Minimum

- Cleaning Method

- Easy cleaning

- Automation

- Touch operator panel, Continuous weighing, Vibration dosing time automatically adjusted

- Surface for Special Products

- Special surface for frozen and sticky products

- Tailor-made Design

- According to customer request

- Product Compatibility

- Dry, frozen, and some sticky products

- Configurations

- Several configurations of pan size and number of heads

- Working Mechanism

- Vibratory feeding

- Automation Level

- Touch operator panel

- Batch vs. Continuous Operation

- Batch or Continuous

- Cleaning Method

- Easy cleaning

- Product Distribution

- Vibration cone on top

- Maintenance Requirement

- Minimum maintenance

- Noise Level

- Minimum noise level

- Product State

- Dry / Frozen / Sticky

- Material Handling

- Vibration Feeding

- Product Compatibility

- Frozen, Dry, Sticky Products

- Mixing Capability

- Custom Mix Precision

- Container Size and Shape

- Bags / Buckets / Cans / Glass Jars / Cups / Trays

- Feeding Mechanism

- Vibratory Chutes

- Pan size

- 10/12, 14/18, 20/24, 28/32

- Number of heads

- 10-28

- Vibratory feeding

- Yes

- Touch operator panel

- Included

- Vibration cone on top

- Yes

- Configuration

- 10/12, 14/18, 20/24, 28/32

- Discharge method

- Vibration dosing time control

- Compact footprint

- Yes

- Control Panel Type

- Touch operator panel

- Design Customization

- Tailor-made design according to customer request

- Product Contact Materials

- Specially adapted for handling sticky products