Batch freeze drying system for food and beverage preservation

Achieve precise and efficient preservation of your food and beverage products with advanced freeze drying technology, enhancing shelf life while maintaining nutritional integrity and flavor.

Processes and Preserves Food and Bioactive Ingredients

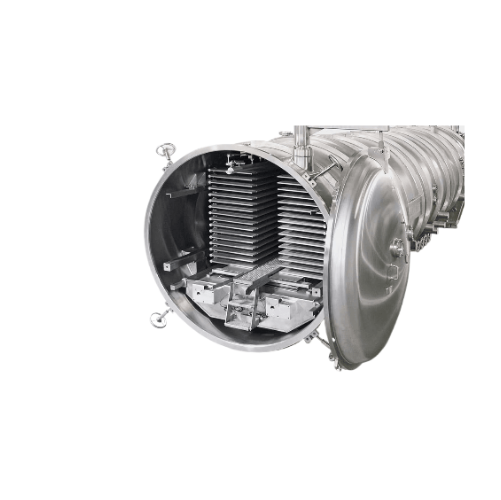

The RAY® Freeze Dryer series from GEA offers versatile freeze drying solutions tailored for food, beverage, pet food, and biotech industries. These dryers excel in preserving nutritional value and extending product shelf life through precise sublimation processes. The RAY® batch and continuous freeze dryers accommodate diverse applications, from freeze-dried fruits and vegetables to bioactive products like probiotics and enzymes. RAY® models, such as RAY®1, RAY®125, and RAY® Pilot Plant, process input volumes ranging from 20 kg to 30 tons per day. Integrating energy-saving technologies and automated features, they ensure efficient operation with minimal supervision. The modular design facilitates rapid installation while ensuring scalability and seamless integration into existing production lines. Constructed from robust materials, the dryers support high hygiene standards with optional sanitary designs. Available with CIP systems, these dryers offer easy maintenance, contributing to consistent operational reliability. Customization options and GEA’s engineering support further enhance process optimization, aligning with specific production goals.

Benefits

- Enhances product preservation and shelf life by maintaining nutritional integrity and flavor.

- Reduces energy consumption and operational costs with integrated heat pump technology.

- Facilitates flexible production scaling with modular and configurable capacity options.

- Simplifies installation and setup, minimizing downtime and associated costs.

- Ensures consistent product quality with fully automated control systems and precise process monitoring.

- Applications

- Food, Beverages, Ready meals, Seafood, Bioactive products, Pet food, Bacteria, Meat, Fruits, Enzymes, Vegetables, Tea, Instant coffee, Probiotics

- End products

- Freeze-dried smoothies, Freeze-dried fish, Freeze-dried strawberries, Freeze-dried mushrooms, Freeze-dried pineapples, Freeze-dried leeks, Freeze-dried pet food, Freeze-dried meat, Freeze-dried blackberries, Freeze-dried instant coffee, Freeze-dried snacks, Freeze-dried tea, Freeze-dried vegetable mix, Freeze-dried ready meals, Freeze-dried fruit mix

- Steps before

- Preparation, Loading product trays, Programming unit, Conveyance of trays using overhead trolley system

- Steps after

- Unloading product trays, Packaging, Inspection of freeze dried products, Quality control

- Input ingredients

- fruit, vegetables, pet food, meat, seafood, probiotics, convenience foods, instant coffee, tea, ready meals

- Output ingredients

- freeze dried fruit, freeze dried vegetables, freeze dried pet food, freeze dried meat, freeze dried seafood, freeze dried probiotics, freeze dried convenience foods, freeze dried instant coffee, freeze dried tea, freeze dried ready meals

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 20-30 kg/day to 20-30 T/day

- Automation

- Fully automated

- Batch vs. continuous

- Batch

- Heating plates

- Built-in

- Vapor condensers

- Integrated in unit

- Drying time

- 8–48 hours

- Cycle time

- 24 hours of freeze drying

- Product loss

- Less than 0.1%

- Freezer type

- Cylindrical cabinet

- Sublimation capacity

- High

- Temperature control

- Precise

- Vacuum control

- Precise

- Energy Usage per Batch

- Reduced with high efficiency refrigeration systems

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Fast setup and installation

- Modular design / Fast installation

- Energy efficiency

- High efficiency / Energy-saving

- Cleanability

- Easy access for cleaning and maintenance

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Cylindrical freeze drying cabinet

- Discharge method

- Front door for loading and unloading product trays

- Control panel type

- GEA Codex® control and automation system

- Compact footprint

- Modular design with connections at the rear

- Batch size

- 20-30 kg/day (RAY®1) to 20-30 T/day (6 x RAY® 125)

- Heating plates

- Included as a part of the complete unit

- Vapor condensers

- Built into the cabinet as a complete unit

- Overhead trolley system

- Used for conveying trays

- Unit configuration

- Batch freeze drying setup

- Control panel type

- GEA Codex® control and automation system

- Integration possibilities

- Full batch reporting, data management, and visualization tools

- System configuration

- Modular design

- Capacity customization

- 20-30 kg/day to 20-30 T/day

- Heating system

- Integrated heating plates

- Condenser integration

- Vapor condensers built as a complete unit

- Sanitary design

- Full sanitary design available