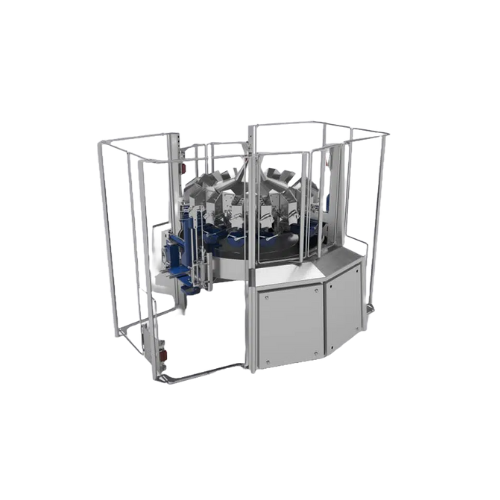

Multihead weigher for sticky products

Efficiently tackle the challenge of weighing extremely sticky products like mixed salads and tuna flakes while reducing labor costs and contamination risks with advanced combinatorial weighing technology.

Automates Weighing of Sticky Food Products

The Multihead Weigher SF Extreme from Cabinplant revolutionizes the way you handle extremely sticky food products. Leveraging a screw feeding principle originated in 2005, this equipment excels at precise combinatorial weighing, significantly reducing manual labor by up to 70% and minimizing contamination risks. Ideal for products like coleslaw, tuna salad, and pulled meat, it efficiently supports industries ranging from meat and poultry to dairy and convenience foods.

Designed with a compact 1,750 mm height, it integrates seamlessly into any production environment without building height restrictions. The system is PLC-controlled, allowing for easy automation and monitoring of production lines, and is capable of handling mixed solids and slurry products continuously and at high speed. Its cleaning process is remarkably efficient, lowering time requirements to just 5-10 minutes, ideal for operations with frequent product shifts. The weigher’s compact design, paired with its efficient energy use and low give-away costs, ensures cost-effective and streamlined production.

Benefits

- Cuts manual labor by up to 70%, increasing operational efficiency.

- Enhances food safety by reducing human contamination risks.

- Integrates easily into constrained spaces due to its compact design.

- Minimizes cleaning downtime with quick 5-10 minute changeovers.

- Maximizes precision and reduces product waste with accurate combinatorial weighing.

- Applications

- Seafood, Dairy food, Berries, Convenience food, Pet food, Meat, Vegetables, Poultry, Fish

- End products

- Smoked salmon, Marinated tofu, Mixed vegetable medley, Rte pasta salad, Cheese curds, Gourmet pet food, Coleslaw mix, Berry compote, Chicken strips, Tuna salad, Pulled pork, Cottage cheese

- Steps before

- Product Preparation, Ingredient Mixing, Initial Processing

- Steps after

- Packaging, Sealing, Distribution

- Input ingredients

- extremely sticky products, mixed salads, coleslaw, tuna flakes, RTE pasta salads, wet and sticky products, pulled meat products, cottage cheese, fruit, vegetables, convenience food

- Output ingredients

- precisely weighed sticky products, automated product batches, reduced give-away costs

- Market info

- Cabinplant is known for designing and manufacturing tailored processing solutions for the food industry, specializing in fish, seafood, fruits, and vegetables. They are reputed for their innovative technology and efficiency in delivering customer-specific engineered-to-order equipment.

- Automation

- Automated/Manual reduction by up to 70%

- Capacity

- Extremely sticky products

- Cleaning time

- 5–10 min

- Footprint

- Height 1, 750 mm

- Handling ability

- Sticky products like mixed salads, coleslaw, tuna flakes

- Weighing method

- Combinatorial weighing with screw feeding principle

- Accuracy

- Higher weighing accuracy

- Flexibility

- Ideal for small production batches with frequent product shifts

- Automation level

- PLC / Manual / Automatic

- Cleaning time

- 5-10 minutes

- Batch vs. continuous operation

- Batch / Inline Continuous

- Handling capability

- Sticky products

- Changeover time

- 5-10 minutes

- Cleaning method

- Easy Clean

- Labor reduction

- Up to 70%

- Footprint size

- Extremely small

- Combinatorial weighing

- Efficient and precise

- Height

- 1, 750 mm

- Cleanability

- Easy to clean, 5-10 min changeover

- Compact footprint

- Height

- Discharge method

- Screw feeding

- Discharge method

- Screw feeding