Cutting solution for large fruits and vegetables

Optimize your food processing operations with a semi-automatic solution designed for efficient slicing, segmenting, and coring of large fruits and vegetables, ensuring precise cutting results and streamlined workflow in your production line.

Cores, Slices, and Segments Large Produce

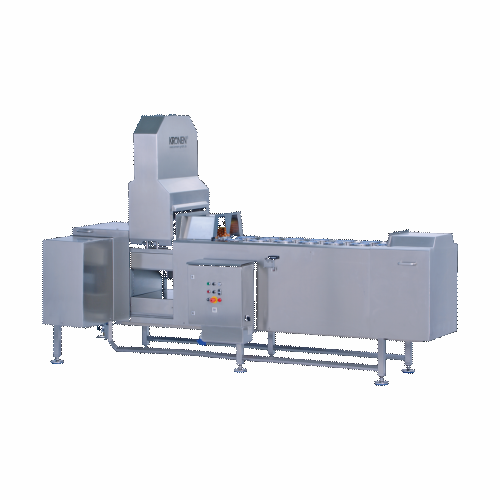

The Tona Rapid XL from KRONEN GmbH is a semi-automatic cutting machine engineered for precision coring, slicing, and segmenting of large fruits and vegetables, such as pineapples and eggplants. This machine stands out due to its double-row product holders, ensuring optimum alignment and a clean cut. It seamlessly integrates into food processing lines, supporting the production of items from vegetable salad mixes to pet food chunks. With a throughput of up to 2,400 pieces per hour, it operates pneumatically for efficient slicing. The Tona Rapid XL offers easy tool changeability with a broad selection of cutting inserts, enhancing its adaptability for diverse applications. Crafted for durability, it is constructed with corrosion-resistant materials and features an intuitive control panel for user-friendly operation. Optional mobile and specialized versions cater to various production needs, making it a versatile choice for food, agriculture, and industrial food service sectors.

Benefits

- Enhances product quality with precise alignment and consistent cuts, ensuring optimal presentation.

- Increases production efficiency by processing up to 2,400 pieces per hour.

- Offers operational flexibility with quick tool changes for varied cutting needs.

- Minimizes waste through efficient separation of good product from off-cuts.

- Facilitates easy cleaning and maintenance with corrosion-resistant materials and a user-friendly control panel.

- Applications

- Baked goods, Salads, Pet food, Meat, Fruits, Vegan products, Vegetables, Fish

- End products

- Fruit salad ingredients, Pet food vegetable chunks, Vegetable salad mixes, Decorative fruit garnishes, Vegan burger components, Eggplant slices, Orange segments, Pineapple slices, Fish fillet portions, Diced meat for stir fry, Beetroot cubes

- Steps before

- Trimming, Sorting, Manual placement in holders

- Steps after

- Separation of good product and waste, Packaging, Weighing

- Input ingredients

- larger fruits, larger vegetables, pineapples, beets, oranges, eggplants, aubergines

- Output ingredients

- slices, segments, cubes, cored fruits, cored vegetables

- Market info

- KRONEN is known for manufacturing industrial food processing equipment, specializing in washing, cutting, peeling, and packaging machinery, recognized for innovation, high quality, and efficiency in automated food processing solutions.

- Capacity

- up to 2, 400 pieces/h

- Cycle time

- max. 1200 cycles/h

- Max Diameter of Raw Product

- 130 mm

- Max Height of Raw Product

- 220 mm

- Cutting Thickness

- min. 5.2 mm (1 mm steps)

- Electric Power

- 0.55 kW

- Voltage

- 230 V

- Frequency

- 50 Hz

- Working Pressure

- 6 bar

- Air Consumption

- 86, 400 NL/h

- Dimensions (LxWxH)

- 3300 x 1200 x 1700 mm

- Weight

- 820 kg

- Infeed/Placement Height

- 1222 mm

- Outfeed/Delivery Height

- 590 mm

- Automation

- Semi-automatic

- Cutting Mechanism

- Pneumatic

- Product Alignment

- Manual Placement in Product Holders

- Automation Level

- Semi-Automatic

- Batch vs. Continuous Operation

- Batch

- Air Consumption

- 86, 400 NL/h

- Working Pressure

- 6 bar

- Changeover Time

- Quick Change of Cutting Inserts

- Cleaning Method

- Manual

- Capacity

- Up to 2, 400 pieces/h

- CIP/SIP

- N/A

- User Interface

- Control Panel

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- 3300 x 1200 x 1700 mm

- Infeed/Placement Height

- 1222 mm

- Outfeed/Delivery Height

- 590 mm

- Maximum Diameter of Raw Product

- 130 mm

- Maximum Height of Raw Product

- 220 mm

- Product Holder Type

- Double-row, manually placed

- Discharge Method

- Separate belt for good product and waste

- Weight

- 820 kg

- Cutting inserts

- Interchangeable inserts for slices, segments, cubes

- Control panel type

- User-friendly control panel

- Mobile version

- Equipped with casters for flexible use and cleaning

- Discharge method

- Separate discharge belt for good product and waste

- Product holders

- Adapted for larger and taller products