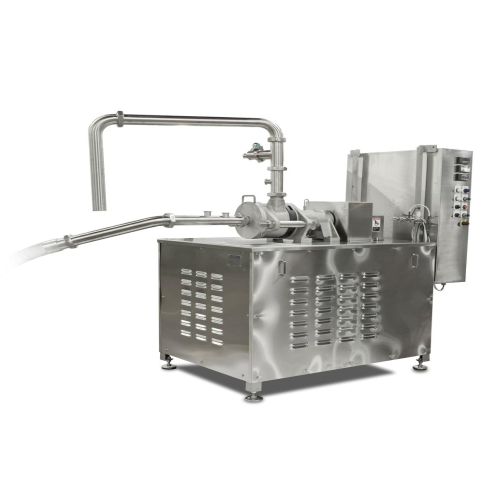

Emulsion and reduction system for meat processing

Achieve precise particle consistency and texture control in food processing, perfecting emulsions and reductions for superior end-product quality.

Reduces and Emulsifies Meat Products Efficiently

The PrimeCut AR922 Emulsion/Reduction System from Cozzini is engineered for rigorous meat and food processing applications, ensuring precise particle reduction and emulsification. Featuring a professional-grade MultiCut Ø9″ diameter (230 mm) cutting system, it utilizes a variable speed pump for controlled product feed into the reduction chamber. This system is adept at producing uniform textures suitable for an extensive range of end-products such as meatballs, bologna, and gourmet pet food. The AR922 seamlessly integrates into production lines, connected to upstream equipment like horizontal screw loaders, and minimizes the need for additional handling. Its design conserves space by replacing conventional bowl choppers and emulsifiers, while reducing energy consumption and labor costs. Customizable configurations are available with various plate and knife options, catering to specific texture requirements. Compliance with USDA and CE standards underscores its commitment to sanitary design and safety. Maintenance is simplified with automated start/stop, bone/gristle elimination capabilities, and contamination prevention mechanisms.

Benefits

- Ensures consistent product quality with precise particle reduction and emulsification.

- Reduces labor and energy costs by eliminating the need for conventional bowl choppers and separate handling equipment.

- Enhances production efficiency with automated start/stop operation and seamless integration into continuous processing lines.

- Meets stringent sanitary standards for food safety with USDA acceptance and CE approval.

- Customizable for diverse product textures with a range of plate and knife configurations.

- Applications

- Meat paste, Pet food, Meat processing, Burgers, Food processing, Emulsions, Ground meat, Sausages, Reductions

- End products

- Chicken nuggets, Meat loaf, Meatballs, Salami paste, Minced meat, Liver sausage, Bologna, Hamburger patties, Luncheon meat, Pâté, Gourmet pet food, Frankfurters, Hot dogs, Processed cheese spread

- Steps before

- Product Loading, Initial Grinding, Pre-trimming, Temperature Monitoring

- Steps after

- Product Discharge, Texture Verification, Temperature Stability Check, Packaging

- Input ingredients

- meat, bone, gristle, emulsion materials

- Output ingredients

- reduced meat particles, emulsified product, selected texture product

- Market info

- Cozzini (Middleby) is known for manufacturing industrial food processing equipment, specializing in grinding, mixing, and emulsifying machinery, with a strong reputation for innovation, quality, and customer service in engineered-to-order solutions for the food processing industry.

- Plate/Knife Cutting System Diameter

- Ø9″ (230 mm)

- Holeplate Sizes Range

- Ø1.0 mm (.039″) to Ø9.9 mm (.39″)

- Product Monitoring

- Inlet Pressure and Inlet/Outlet Temperatures

- Bone/Gristle Elimination

- Available

- Pumping System

- Variable Speed Pump

- Knife Holders

- 3 arm to 6 arm

- Direct Discharge

- To Hoppers

- Automation

- Start/Stop with Optional Hopper Product Sensors

- Working Mechanism

- MultiCut plate/knife cutting system

- Automation level

- Start/stop automation with optional sensors

- Batch vs. continuous operation

- Inline Continuous

- Bone/gristle elimination system

- Available

- Lubrication contamination prevention

- Unique separation design

- Temperature Control

- Product inlet/outlet temperature sensors

- Pressure Monitoring

- Product inlet pressure sensors

- Direct discharge capability

- Via specially designed pumping impeller

- Abrasion resistance

- High

- Biological compatibility

- Food-grade

- Cleanability

- Easy to clean with CIP

- Corrosive resistance

- Stainless steel

- USDA Acceptance

- Yes

- CE Approval

- Yes

- AMI Sanitary Equipment Design Principles

- Yes

- Cutting system diameter

- Ø9″ (230 mm)

- Holeplate size

- Ø1.0 mm to Ø9.9 mm

- Feed method

- Force-fed with variable speed pump

- Discharge method

- Direct to hoppers via pumping impeller

- Plate Hole Size Options

- 1.0 mm to 9.9 mm

- Knife Holder Options

- 3 arm to 6 arm

- Cutting System Configuration

- Single plate and knife or two plates and knives

- Integration with Feed Systems

- Compatible with horizontal screw loader

- Pumping and Discharge System

- Direct discharge to hoppers

- Optional start/stop automation